And there are many factors that cause dead models, the product development stage, large production stage, the sales stage may cause a section of the sales situation is very unsatisfactory.

And for designers, product development stage is what we need to pay attention to. Indeed, a considerable part of the dead models, in fact, is “designed” out, and even in the designer drawing, can determine the fate of the paragraph.

Product development stage, and can be divided into: product factors (shape and color quality), commodity factors (seasonal wave), planning factors (development and implementation) and customer factors.

In this article, I break down the product factors, how to avoid the design of “dead models”? I divided into four parts, briefly talk about: color, fabric, pattern, process.

Color

Color is important to note: acceptability.

Because a piece of clothing. What makes the most impression is its color. The choice of color reflects the customer’s personality and attitude, and color is the primary key factor for customers to come to a decision to buy.

In a sense, the color can become both the core selling point, but more likely to become a minefield. According to my analysis over the years, a considerable number of stagnant models (dead models) inventory pressure because of the color.

That is to say, the color may not determine the upper limit of a paragraph sales, but can certainly determine the lower limit of sales.

We Chinese people generally yellow skin, and the color is too bright clothing is particularly not lined with skin tone, looks dull face or even dark.

For example, a very vegetable very vegetable grass green, the show looks so wonderful, there are many trends in those years to hold this color:.

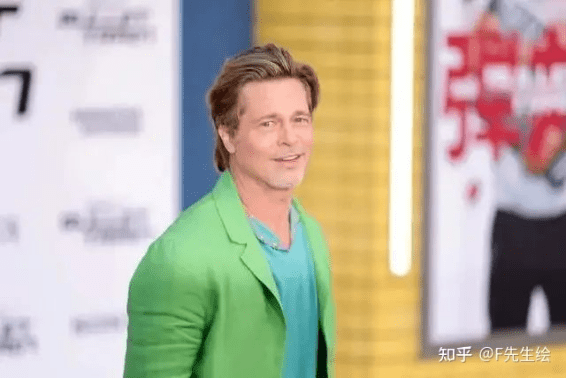

But a little darker skin, a large area to wear on the body, it is called a tragedy …… Even Brad Bitt temperament so good, skin so white big star, wearing this color is so, not to mention the average Asian skin tone:.

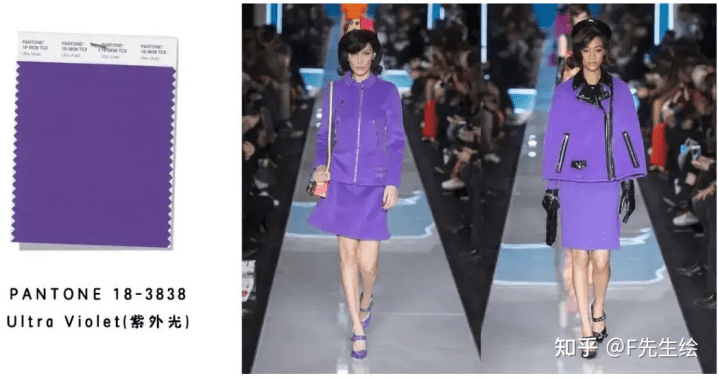

Another example from 2018: the hottest UV color at that time. Yes, Pantone color number 3838 ultraviolet color.

According to my understanding, there are several Guangzhou women’s clothing company, the Pantone color No. 3838 ultraviolet color is the season’s main color, many models apply this color, the use of a large area, the results of the vast majority of pressures, sales are dismal (this color is too high purity is very easy to show black):.

On the contrary, the lavender purple market momentum of light gray is very strong, out of some explosive models. (But at that time, foreign authoritative trend release, rarely mention this color)

The color itself is divided into strong affinity, weak affinity points. If our purpose is to land the color to the market, and strive to do not step on mines, not dead models, that affinity is a must to consider.

When the final popular in the market, in fact, or light gray taro purple (the next year, various domestic brands also followed the color):.

And most of the show deep purple are forced to become unsold “dead models:”

The reason for this is: the purity is too high, too strong shades of purple, in fact, is not friendly to the public. The effect on the body can be imagined. It is destined to be used on a small scale, not on a large scale. At least in the field of clothing fashion, it can only exist as a “trend”, not “popular”.

Therefore, the principle of avoiding “dead models” from the perspective of color is: no matter what the popular color is, always consider the market acceptance, the wearer’s wearing status and needs first.

Fabric

The second “dead” decisive factor, is the fabric.

Fabric to pay attention to is: comfort.

Especially the fabric worn close to the body, if not comfortable to wear, even if the style is designed to have a level, for sales is also a disaster.

Take the fabric of the pants, if not cotton and linen casual style, the pants are to minimize the wrinkles, wear pants most hate pants wrinkles, and then pants to wear comfortable, breathable. So in the selection of pants fabric, to avoid the pants are not breathable, no elasticity, and whether it is easy to produce wrinkles, or whether the wrinkles can be quickly recovered, it should have a certain degree of extensibility.

For example, the following piece of fabric is very special, imitation paper texture, is to imitate the feeling of paper design of a fabric, but neither breathable, poor elasticity and wrinkle resistance is also poor, with this fabric for dresses, the style looks very special, even if the inside is lined to prevent direct contact between the fabric and the skin, but this is still only as a whole tray of goods embellishment, not mass production, after all, wearing comfort is too poor:.

If the fabric is not comfortable, sales will definitely be affected, just the difference in the size of the impact. If the fabric does not match the basic wearable attributes needed for the garment, it will affect sales.

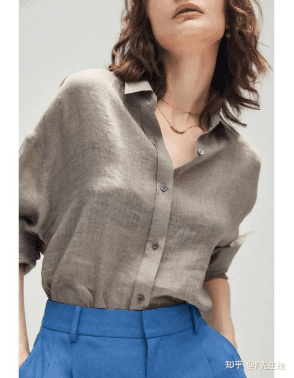

Another example is this ramie fabric garment, the same style, but the post-treatment washing method is different, the wearing experience after the garment is very different

If ordinary washing is used it will produce a prickly feeling, which is very uncomfortable and affects human comfort. However, if enzyme washing treatment is used, it will increase the sales surface a lot because the fabric is softer and more comfortable to wear.

The designer should fully understand the characteristics of the fabric, the possible defects of the fabric, especially the process of the relevant post-treatment, not just a panting, panting, panting drawing, out models. Especially for newly developed fabrics that have not been used on a large scale, they must be tried on by real people to ensure comfort.

Note that the material composition is not the only factor that determines comfort. For example, a simple style of summer wear short-sleeved TX, the fabric is 100% C single-sided sweat cloth: the

Plain combed cotton feel rough, loose, wear after washing deformed.

Combed cotton use the most common varieties, compared to combed, the feel will be obviously delicate and soft a lot.

Combed cotton enzyme wash etched hair, after this process, the fabric immediately high, the surface has a slight sense of velvet, introverted temperament so that people love to give up their hands.

Cotton double mercerization, after the mercerization process, the surface of the fabric has a silk-like luster, cool and lubricious to the touch.

Although they are all cotton, but the characteristics and value of the sense of difference to go thousands of miles, so designers must be clear about these differences.

Fit

One thing to keep in mind about fit: inclusiveness.

For example, one year very hot big shoulder pads is a typical T-shaped silhouette, but note that it is very demanding on the body. Because the T-shaped silhouette is easy to press the person short and fat:.

There is also the wrap type, which is the most figure-hugging, so it is generally used for close-fitting inner wear. Unless the body does not have an ounce of fat and has a slim bone structure and perfect proportions, few people will choose the wrap version:.

Loose fit is the fit that suits most people and is the most popular fit these days. It does not emphasize the curve, nor does it require the body, conveying a casual dressing attitude. It’s not that this type won’t come out dead, the market positioning is different for different versions, the only guideline is tolerance.

Style details, such as this small flying sleeves and “faux sleeveless” design, there is no supermodel body, it seems a minute arm lanky circle, and fat and strong. This is something that designers can easily overlook when designing.

In the design of the time to pay attention to, a good version of the clothes will show the body, the body is not good, wear a good version of the clothes can also cover up the defects.

Craftsmanship

Craftsmanship should be a big part of the designer’s design “deadlines”.

The process should pay attention to: reasonableness.

For some established rules, must comply with, this is fixed, no way to change the rules. For example, clothing printing (offset printing), we must pay attention to the area of the print.

Some designers take for granted, the whole garment large print, and with offset printing process, in fact, is not considered the wearer experience, because it is too hot and stuffy.

Especially the summer models, do not large area offset printing, because the location of the garment printing coated with a layer of paste, the location of the fabric is not breathable, the human body sweat more in the summer, if a large area printed pattern can not be very breathable perspiration.

I N years ago to do designers have stepped on this mine, the original design elements of a very good pattern T-shirt models, because of this reason pressed a lot of goods can not be sold.

Also, the less mature, expensive process, we must be careful to choose, careful to play the version, careful to order, it is best to be tested several times before using.

For example, this embroidery process (fringe embroidery) is popular from 2017.

At that time, many brands are doing this process, but this process has a problem, that is, once the tassels absorb water, those threads are all stirred together, either broken, or stirred together, so the negative impact on the repurchase and brand are very large. At that time, a considerable part of the company, made this process of the paragraph were called back, the return rate is very high.

In recent years, the rationality of this process has improved some, so we still need to pay attention to the new process must be tested, washed, especially after a period of experience before developing.

Of course, having said that, the meaning is not which things must not be done. These have to be considered together with product positioning and other factors, it’s just a matter of how much and in what proportion. How to combine commodity factors (seasonal wave), planning factors (development and implementation), customer factors, I will come back to later.

Quoting a member of the group, what is the ability needed to avoid “dead models” from the product perspective.

I have some thoughts about fitting. If you think of yourself purely as a mannequin feeling to try on clothes, you have no emotion, you try on clothes will not feel.

But if you feel like you are wearing it as a consumer, it will help you a lot in your design development.

Can you understand how your clothes can be comfortable to wear and how they can be functional? The fitting staff on our side doesn’t have a good feeling about the clothes either, so the directors and supervisors of the company will try on the clothes themselves to feel from the standpoint of consumers.

This brings a great help to the product upgrade, the director will go to wear the clothes himself, also affect the wearing feeling of the fitting model.

Also, our company used to have a fitting assistant and designer assistant, after wearing clothes for two years, go out to be a designer, other company bosses especially like her, because she not only knows the effect of wearing each piece of clothing, but also understand the size to understand the shape, so the design of the clothes restoration degree is particularly high.

Finally, how to avoid the design of “dead models”? From a product perspective, I outline four aspects.

1. color to pay attention to is: acceptability

2. the fabric to pay attention to is: comfort

3. the shape to pay attention to is: inclusive

4. process is to pay attention to: reasonableness