Coating printing

Paste: water paste, glue paste, ink paste, water-based glue paste, etc.

Practice: The modulated paste is printed directly onto the T-shirt garment or cloth piece through the screen. Suitable for field single color or dot, line, block surface multi-color printing.

Features.

The advantage of water pulp is good breathability, relatively cheap, the disadvantage is that the color is not bright enough, poor coverage, printing is suitable for cotton fabrics, can not print light colors on dark fabrics.

The advantage of ink pulp is bright color and strong coverage ability, the disadvantage is relatively poor breathability, odor; not suitable for waterproof coating fabrics.

The performance of water-based pulp and semi-glue pulp is between ink pulp and water pulp.

Silicone Printing

Silkscreen silicone is a non-toxic, non-hazardous and environmentally friendly material. Silkscreen silicone is a special silicone that can be firmly adhered to the surface of textiles, non-woven fabrics and other materials through screen printing.

Silkscreen silicone is extremely versatile. The silkscreen silicone pattern has a strong three-dimensional feeling, with a soft hand, high transparency, bright, strong three-dimensional feeling, waterproof and old-fashioned, no discoloration, non-slip, breathable, high and low temperature resistance, and good leveling properties.

Foam printing

It is printed directly on the T-shirt fabric through the screen, and the foam microcapsules swell rapidly when heated to form a three-dimensional embossed pattern, which has the advantages of good fastness, washing resistance and soft handfeel.

Only suitable for single-color dot and line printing, not very suitable for block and dot printing. Combined with other forms of printing process can achieve good results

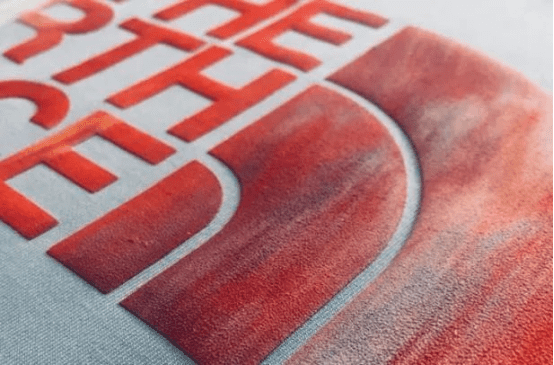

Ink thick plate printing

Ink is printed directly on T-shirt garments or fabric pieces by using a thick film photopolymer thickened stencil to form a relief effect of embossed patterns. Suitable for single-color dot, line and small surface printing, and other printing processes combined with printing can achieve a good three-dimensional visual effect.

Static flocking printing

It is a three-dimensional embossed pattern that is formed after heating and curing by putting the adhesives suitable for electrostatic flocking and printing directly on the T-shirt garment or cloth piece through the screen, and then planting the fiber fluff in the adhesive in a directional, vertical and uniform way through electrostatic, and its appearance is unique.

Electrostatic flocking printing is suitable for single-color and multi-color pattern printing, and can be printed with other printing products.

Transfer flocking printing

Using electrostatic flocking to produce flocking paper, we make single-color flocking paper and multi-color flocking transfer paper, and then transfer the pattern on T-shirt fabric through screen printing and heating and pressure.

It has the advantages of simple and convenient operation, low cost, beautiful products and washability, and can be suitable for transferring on T-shirts of various color fabrics.

Pearlescent printing

The printing paste contains special inorganic crystals of mica titanium, which has over-surface reflective properties. It is printed on T-shirt garments or fabric pieces to produce a pearl-like luster to the pattern. It can be cross-printed with other printing processes. Can be combined with a variety of printing products and suitable for various types of patterns.

Gold and silver powder onion printing

Containing gold glitter, silver glitter, laser glitter, colorful glitter and other pastes printed on various colors of T-shirt fabric, so that the pattern is lustrous, gold rich, silver gorgeous, laser colorful colorful.

Gold and silver foil paper

The adhesive is printed directly on the T-shirt fabric through the screen, and then after heating and pressurizing the aluminum electrochemical and T-shirt fabric, the “color foil” of the aluminum electrochemical is transferred on the T-shirt fabric to form the pattern. Gold, silver fastness is more stable, color is relatively poor, black can not pass the inspection needle. Can be suitable for a variety of fiber fabric T-shirt.

Three-dimensional stamping printing

Stereoscopic foil stamping technology is a combination of foil stamping technology and embossing (three-dimensional embossing) technology of a composite technology, is the use of etching or engraving technology, foil stamping and embossing of the pattern, made into an up and down with the negative die concave and positive die convex version, is the process of foil stamping and embossing technology completed at once

Dyeing printing

Through the screen plate to destroy the fabric’s own color dye printing on the fabric, and then after heating and pressure plucking color and get a variety of patterns, and then combined with offset printing and other printing processes to obtain more color patterns, widely used in T-shirt pattern printing on a printing process. (Fabric coloring should use pluckable dyes, and the finished garment should be washed to remove the residual dye.)

Ideal for use in styles that need to reflect natural, layered patterns, such as denim and twill cotton and oxford fabric are perfect.

Confusing knowledge point: how to distinguish between plucking and piquant dyeing?

The color of the bottom color on both sides of the fabric is the same as that of the dyeing print.

If the shade of the surface color is different from the bottom color, and the bottom color is darker, it can be confirmed that it is plucked dye printing.

Reduction printing

Also known as burnout printing or rotten printing, the use of interwoven or mixed fabrics of different fibers in the chemical resistance of the differences in nature, through the printing method applied burnout agent in the fabric local removal of one of the fibers, retain other fibers and the formation of translucent pattern.

Thermal Sublimation Transfer Paper Printing

Also known as “gas dyeing”. Under the condition of high temperature around 200℃, the dye type ink with sublimation condition is directly changed into gas state without liquefaction, and the fabric is directly dyed into a specific pattern.

The transfer paper can be produced through flatbed printing (offset printing), screen printing, gravure printing, computer color spray printing and other methods, and the design is transferred to the T-shirt after heating and pressing. The graphics are fine and realistic, with high color fastness, strong breathability and brilliant color.

But limited to high temperature resistant part of the synthetic white or light-colored fibers on the fabric, such as: polyester, acrylic, etc., can not be applied to cotton fiber fabrics.

Computer digital printing

Use the computer and related software to edit the image and then input the high-tech digital T-shirt printing equipment for printing. Colorful, clear pattern, no pollution, no starting amount of printing and other characteristics.

But it can’t print special materials, such as: foam, gold and silver glitter, reflective, glue beads, thick plates, plucking and dyeing, etc.

Hot Stamping Transfer Printing

Also known as offset transfer printing or photographic plate transfer printing. It uses a combination of lithographic printing, screen printing and chemicals. It has the characteristics of clear graphics, realistic expression of natural scenery, and can achieve photo-like quality and strong washability. Through heating and pressure can be printed on various types and colors of T-shirt fabric.

Reflective Printing

Ink resin with special reflective material glass beads, through the screen directly printed on a variety of colors T-shirt fabric, in places where the sun is not sufficient or at night, using their own light and external light source reflection issued light.

This process is suitable for printing all types of fabrics.

Light change printing

Several kinds of high-tech ultraviolet light-excited spark micro-gel particles are added to the dye, and the color changes instantly when irradiated by ultraviolet light.

Easily cracked and not washable. Same design application as offset printing is recommended.

Bead printing

Plant beads also called toothbrush flowers, the finished product effect is like a vertical toothbrush beard and named, I heard that a flower to print 20 or 30 times to print well, the finished product height can reach about 0.3CM, its top is bead-like, you can do other colors on it, seems to be topped with a bead in general, so also called plant beads.

Stone Paste

If gum paste is neat, then stone paste is spontaneous. Have you ever noticed the footprints you just left when you walked on a muddy road? It is almost like that effect, it looks like a block or a strip of stone shape or mud shape, it is a relatively new variety of printing. Mostly seen in casual menswear.

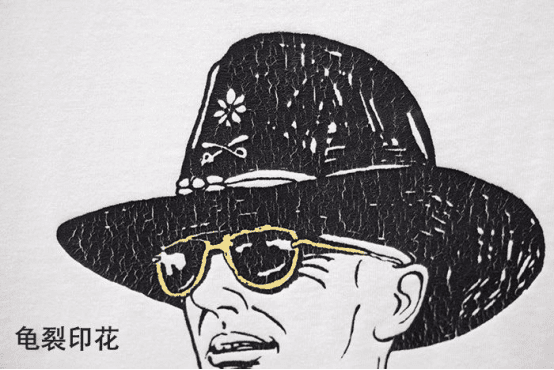

Cracking

A printing paste that contains a special heat shrinkage and hardening and brittle component.

It is printed directly on the T-shirt fabric through the screen and then dried to naturally form a special effect like the cracking of a turtle’s back. It can be combined with a variety of printing processes and can be used for various types of patterns.

Types of dyeing applicable to garment design

Hanging dyeing

The fabric is made of natural fabrics such as cotton, (cotton stretcher) wool, linen, silk, etc. Only nylon is suitable for this process. Other chemical fiber materials are not suitable for this process.

Fabric is best to use this white blank fabric, fabric if the pre-dyeing after bleaching, color fixation and other post-processing, in the process will add some chemical agents, and later then garment dyeing will affect the dyeing effect of color flowers and other problems, increasing the loss and risk.

The fabric should be degreased, shaped and washed in advance to ensure the stability of the garment size. (It is best for the garment dyeing factory and the fabric factory to communicate directly about the specific operation of the fabric in the early stage.)

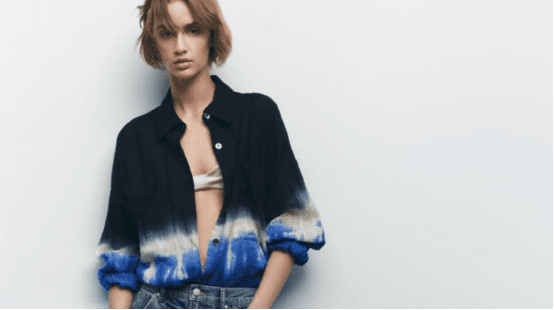

Hanging dyeing is to fix the clothes on the hanger and then partially dip them into the dyeing solution to produce different color effects up and down. It can make the fabrics and garments produce a gradual, soft and peaceful visual effect from light to dark or from dark to light. Previously more used in cotton and linen or literary style clothing, in recent years more and more casual/fashion brands also use a lot of.

In recent years, with the release of PRADA, Fendi and other first-line brands, this special dyeing technique of hazy gradient has become an indispensable dyeing means for clothing.

Advantages: color has a sense of hierarchy Disadvantages: low yield, cylinder difference, color is not allowed

Tube Dyeing

Tube dyeing is dyeing in the form of tubes and is generally used to dye yarn or pique. This will not be used for ready-to-wear designs.

Segment dyeing

Segment dyeing is the process of laying out twisted yarns and spraying them with different colors at certain design intervals to create a segmented color effect. The advantage of segment dyeing: it can form the effect of rich color. Disadvantages of segment dyeing: The disadvantage is that it is easy to have regular patterns and the color fastness is not good. It is generally dyed yarn.

Garment dyeing

It is the process of dyeing the garment after it is finished. Garment dyeing method is a process especially for cotton, garment dyeing, also called finished dyeing. Advantages: good texture and hand feel. Disadvantage: Size is difficult to control.

Spray dyeing

The dyeing method is similar to segment dyeing, except that the dye is sprayed in an irregular manner. Advantages: Color changes. Disadvantages: requires manual labor and is difficult to process.

Tie-dye

It is to tie up the clothes in a certain way to produce uneven dyeing, thus forming irregular geometric patterns. Tie-dye fabrics: hand-made tie-dye fabrics are usually cotton, hemp, wool, etc., and the choice is mainly based on the different products made. (pure natural fiber fabric)