Difference between knitted fabric and woven fabric

Knitted fabrics and woven fabrics are different in terms of processing, fabric structure, fabric characteristics, and finished product usage due to their different knitting methods.

Many designers, especially design assistants who are new to the job market, are confused on this, so here are some comparisons.

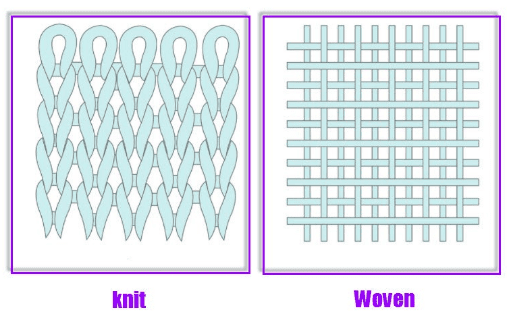

The composition of the fabric organization.

(A) Knitted fabric.

Is bent by the sequence of yarn into a coil, and the coil in series with each other and the formation of fabric, and the process of yarn formation coil, can be horizontal or vertical, horizontal knitting is called weft fabric, and vertical knitting is called warp knitted fabric.

(B) woven fabric.

Is made of two or more groups of mutually perpendicular yarn, to 90 degrees angle for warp and weft interwoven fabric, longitudinal yarn called warp yarn, transverse yarn called weft yarn.

Basic unit of fabric organization.

(A) Knitted fabrics.

A bobbin is the smallest basic unit of a knitted fabric.

(B) woven fabrics.

Each intersection point between warp and weft yarns is called a tissue point and is the smallest basic unit of woven fabrics.

Fabric tissue characteristics 1.

(A) Knitted fabric.

Can be extended in all directions, good elasticity, because the knitted fabric is formed by the hole-like coil, there is a large air permeability performance, feel loose.

When the knitted fabric is subject to external tension, the bending of the coil changes, so the extension of the knitted fabric is large.

(B) woven fabrics.

Because the woven fabric by, weft yarn extension and contraction relationship is not large, also does not occur conversion, so the fabric is generally tight, stiff.

When the woven fabric by external tension, warp, weft yarn will not be converted, and knitted fabrics are different.

Physical properties of fabric tissues.

(A) Knitted fabrics.

Physical properties of fabric, including longitudinal density, transverse density, square meter grammage, elongation properties, elasticity, breaking strength, abrasion resistance, rolled edge, thickness, dispersion, shrinkage, coverage, bulk density.

(B) Woven fabrics.

The physical properties of woven fabrics, including warp and weft yarn density, cloth edge, front and back, down and reverse hair direction, fabric coverage.

Roman Fabric

What kind of fabric is Roman fabric?

Roman cloth is a knitted fabric, weft knitted, made by double-sided large circular machine. It is also called ponte-de-roma, commonly known as chicken-fighting fabric.

It is a kind of fabric made of natural combed cotton blended with elastic hidden light cellulose, is a kind of unique textile technology product of Italy using high-end technology.

Roman fabric according to raw materials: there are polyester-cotton raw materials, nylon cotton, all-polyester, cotton-polyester, polyester spandex, general square gram weight in about 200 grams, the fabric is thicker.

Nylon cotton Roman fabric generally speaking, there are three components, nylon spandex cotton, this cloth belongs to the double-sided knitted cloth, front and back can be done outside the clothes, due to this feature to expand the use of the fabric. In addition, this fabric is not easy to hook, not easy to pilling, is the ideal knitting fabric to do the jacket.

Roman cloth is not easy to stick to the hair, dust, dirty and easy to wash! Stretchy, feel a variety of soft, can be wide.

Because the Roman cloth is relatively thick, stopping the mouth flat is not easy to take off the yarn, so many clothing styles use this excellent characteristic of the chicken cloth to do loose mouth burlap design.

But because the Roman cloth elasticity is very good, generally contains 6 percent of the point of spandex. If a long time under pressure, twisting, high temperature will cause spandex yarn aging, fracture, shrinkage, so that the clothing deformation can not recover.

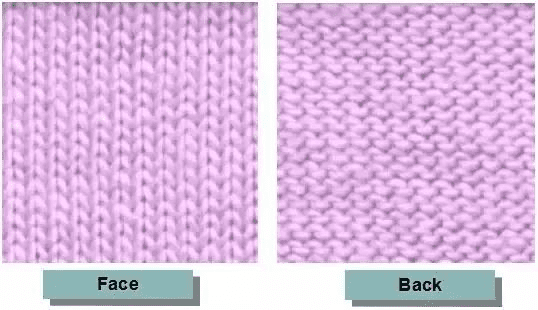

Is there any front and back side of Roman fabric?

Theoretically, there is no difference between front and back of Roman cloth, if there is only a small piece of cloth, it is difficult to distinguish front and back, if there is a whole cloth cover, you can determine which side is the face and which side is the bottom according to the shaping pinhole.

If it is color woven Roman cloth, there is a very obvious color difference between the front and the back, and it is clear at a glance.

jersey

Sweat cloth is the most basic of all circular knit fabrics. It is what we most commonly call T-shirt fabric.

Chinese name: Single jersey or jersey. English name: Single jersey or jersey.

It is used in knitted garments for spring and summer T-shirt, fashion, underwear in autumn and winter, sports and leisure knitted garments, and also can be widely used in composite fabrics. It is the most common and widely used knitted fabric.

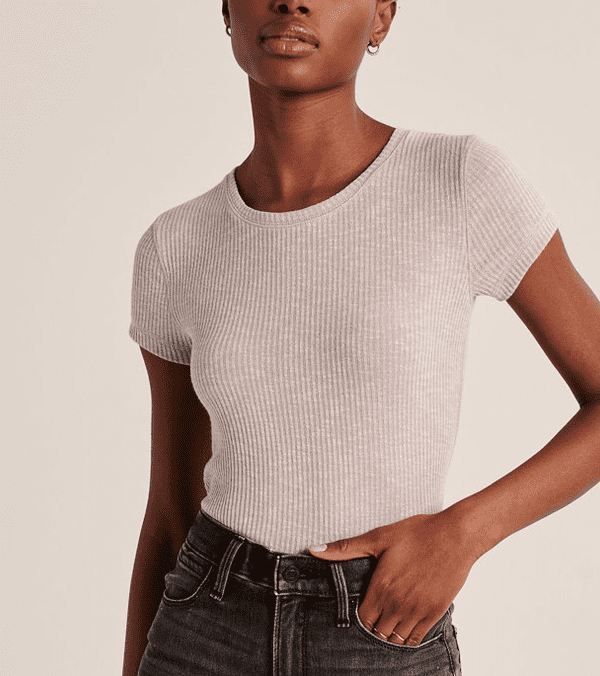

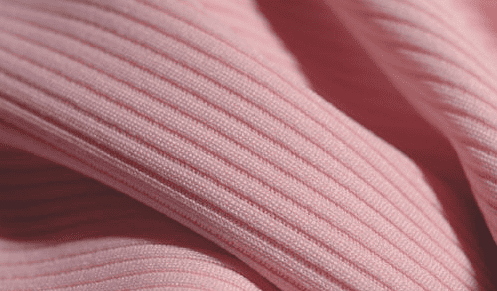

Ribbing

Ribbing is made by alternating loops on both sides of the needle barrel. The most common types are 1*1 ribbing and 2*2 ribbing.

Designers often get confused about the term 2*2 and 2*1. Generally speaking, it is more appropriate to call it 2*2.

Features of ribbed knitted fabric: good lateral elasticity. Suitable for tight-fitting apparel and closure function, etc.

What is the difference between horizontal ribbing and circular ribbing?

Round machine ribbing (relatively thin and soft)

1、Blank cloth is cylindrical.

2, due to the fine gauge (generally 15G or more), the fabric surface pattern is fine, compared to the thinner cloth.

3, generally used as knitted garment big body cloth or rolled edge, or round neck T-shirt collar edge.

Horizontal machine ribbing (relatively thick and stiff)

1.Blank cloth is piece-like, and each piece has unraveling lines.

2.The gauge is coarse, the cloth style is coarse, the cloth is thick, and it is usually woven with several strands of yarn.

3.generally used as the collar, sleeve parts of knitted lapel T-shirt, woven jacket collar edge, cuffs, hem parts.

Cotton wool fabric

Cotton wool fabric, now refers to the double ribbed fabric, not the fabric with “cotton” and “wool” components, generally has a good horizontal elasticity.

Cotton, rayon, soybean fiber, colored cotton, modal, bamboo fiber and other raw materials made of cotton wool tissue fabric, because of the better skin-friendly, warm breathability, often used as underwear fabrics and baby fabrics.

In the country, many winter wear pants and sleeves underwear, is collectively referred to as “cotton wool pants”, “cotton sweater”. Although the actual fabric used may be stretch ribbed fabric or stretch sweat fabric.

What is the difference between cotton wool fabric and pure cotton fabric?

1.the composition is different.

All cotton refers to clothing or supplies containing 100 percent cotton.

Cotton wool cloth mainly blended cotton wool cloth (cotton blend and ammonia cotton blend), chemical fiber fabrics (acrylic cotton wool cloth, polyester cotton wool cloth and spandex cotton wool cloth). Most of the raw materials are made of cotton yarn with a linear density of 14~28 tex, and the twist degree is slightly less than that of yarn for sweat cloth, in order to increase the softness of cotton wool sweater pants.

2.Different scope of application.

Cotton cloth is generally flat cloth, poplin, twill, labor cloth, etc., different from the general fabric is that it has the advantages of anti-odor, breathable, comfortable, etc. Try not to use laundry detergent, it is best to use transparent soap.

Cotton wool cloth, with thick, soft, good warmth, no rolled edges and a certain degree of elasticity, etc., widely used in sewing cotton wool sweater pants and sweatshirt pants.

3.Different characteristics.

Cotton wool fabric is a double ribbed knitted fabric made of two ribbed tissues compounded with each other, which has the characteristics of soft hand, good elasticity, even cloth surface and clear grain.

Cotton is easy to wrinkle, and easy to deformation, lack of elasticity, cotton clothing will be easy to deformation, especially summer clothing, because the fabric is relatively thin.

Sweatshirt Fabric

Knitted sweatshirt fabric, also known as three yarn sweatshirt fabric. It is named after the fact that there are three yarns in one horizontal row of the fabric: plain, tied wool and wool yarn. It is also called “double sweater” because it contains two yarns in the ground tissue, which is different from single-sided terry.

In order to enhance the softness and warmth of the fabric, most of the sweatshirt fabrics are dyed and then brushed with terry on the back.

Since the earlier three-wire sweatshirt fabrics were woven on a dolly, they were also called “dolly fleece”.

Coral fleece

Coral fleece, as the name implies, because its pile style similar to coral.

There are two main types.

1.Weft knitting coral fleece

Polyester as the main raw material, but also with nylon polyester composite silk raw material.

2. Warp knitting coral fleece

Polyester is used as the main raw material. It is knitted on a double needle bed warp knitting machine, and processed by booking, dyeing, brushing, combing, shearing, shaking and other processes.

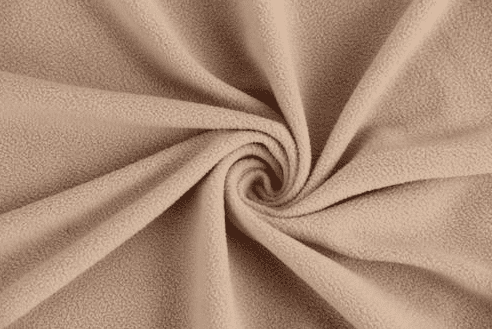

Shaker Fleece

What is shaker fleece?

According to the industry, shaker fleece originated from Taiwan in the 90s, a factory made a special knitted fleece fabric by mistake in order to improve some properties of the fabric, and its fleece surface had a tufted style, which was seen by customers and slowly became popular.

Because of the shaking process, it is also called anti-pilling shake-grain fleece.

Traditionally, shaker fleece is all-polyester fabric, knitted on a circular knitting machine with a positive wrap terry machine.

Nowadays, there are many different types of fleece. The most basic type of shaker fleece is knitted on a circular knitting machine. (In Fujian and Guangzhou, it is mostly called back cover, so it is necessary to distinguish between ground yarn and terry yarn.

Velvet

also called knitted velour, which is said to have a soft, gentle meaning in Russian.

In addition to CVC velvet, the common “velvet” in the market are:

Dense silk velvet

Steam velvet

Not inverted velvet with spandex varieties. The pile is basically upright on the ground cloth, and when you press the pile surface, the pile surface will recover quickly.

Diamond velvet

Diamond pile is the sister of ice flower pile and diamond pile, mainly because the dyeing process is slightly different.

Gold diamond pile is a thicker spandex variety of shearling, and the pile surface is lustrous, similar to warp knitted rich pile.

Raggedy fleece The terry is rayon (or cotton yarn), the ground yarn is polyester, and the rayon has a rotten pattern, and the ground yarn is spandex.

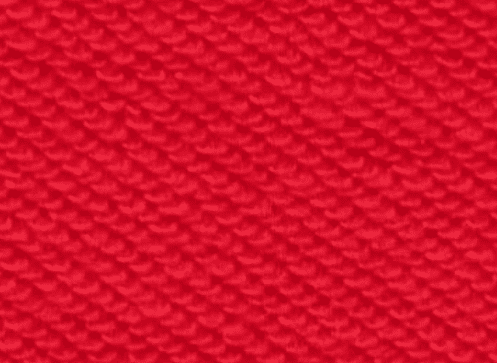

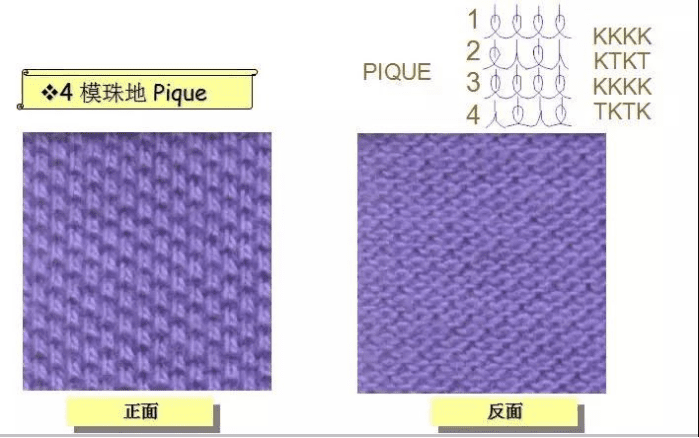

Bead ground mesh

What is beaded ground mesh? Broadly speaking, it is a general term for knitted fabrics with a bumpy style.

Since the fabric has a uniform and neatly arranged bumpy effect, the surface in contact with the skin is better than the ordinary single-sided sweat fabric in terms of breathability, heat dissipation and perspiration comfort.

The narrow meaning is the knitted single-sided garden machine knitting 4 way a cycle of bumpy fabric.

English name: Pique (intaglio fabric)

Since the back of the fabric shows a four-cornered shape, it is common to have the name of four-cornered mesh in the industry.

There is also a common double bead ground mesh. Because the back side of the fabric presents a hexagonal shape, so the industry has the name of hexagonal mesh. Because the concave and convex structure of the back side is similar to a soccer, it also has the name of soccer mesh.

And some look like direct translation of quadrangular mesh, hexagonal mesh, also need to further confirm the fabric organization and style.

Others: Derived from single beaded ground mesh or double beaded ground mesh variations, many different styles of single-sided beaded ground mesh structures can be developed.

Including some alternating beaded ground and sweat fabrics can be woven, appearing vertical stripes, horizontal stripes, squares, etc. More varieties of fabrics can also be combined by jacquard.

There are also fabrics on double-sided knitting machines that have a concave and convex structure, which in some areas are called double-sided beaded ground mesh, and should be distinguished from double-sided beaded ground mesh on single-sided knitting machines. (Double-sided beaded ground mesh will be described later in the common variations of double-sided organization)

Raw materials: common fabrics are cotton, cotton-polyester blends, modal, bamboo fiber, and other raw materials.

Double burnt wool double mercerized fabric, color woven computer large loop color stripes, computer jacquard, computer hanging warp, modal/bamboo fiber/tencel/absorbent and sweat-wicking functional fiber/antibacterial fiber/organic cotton and other fibers. Bead ground mesh fabric in the more high-end varieties

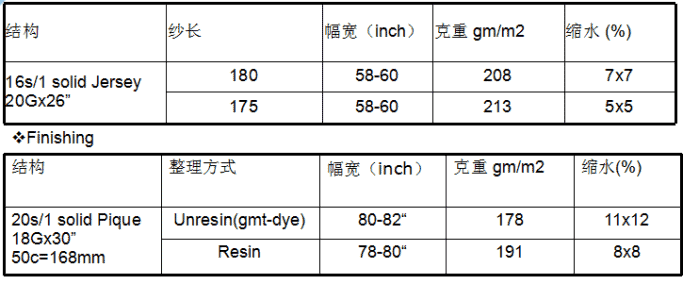

Knitted fabric shrinkage quality problem

Shrinkage Shrinkage

Usually, the shrinkage of knitted fabrics is much greater than that of woven fabrics due to their loose structure.

A good shrinkage of 7% x 7% (AATCC three tumble dry) can be achieved for single-sided sweat fabrics, single bead ground and double bead ground fabrics, and 8% x 8% for double-sided fabrics and ribbed fabrics.

The shrinkage depends on the knitting tension, the type of yarn, and the finishing method.

Improvements for too much shrinkage :

Weave tighter: It will change the weight, width, feel and style of the fabric.

Resin Finishing: It will reduce the strength of the fabric, and resin finishing cannot be added to orders like garment dyeing.

Pre-shrinkage Compact : It can increase the shrinkage by 1-2%.

Fabric Wash: fabric weight and width will change, suitable for some loose fabrics with shrinkage greater than 7×7%.

Knitted fabric style design points

Pay attention to drape

Knitting is drapey, so we have to use drapey and avoid the disadvantages of drapey.

Knitted pleats are not easily deformed after ironing, so you can use inverted pleats, I-pleats. But to use less broken pleats (natural pleats), less pressed cotton lace and polyester lace, suitable for pressing lace lace.

Knitted material is smooth, can do a large arc of folding double neckline, while the woven neckline is not suitable for folding double, more suitable for double stitching.

Pay attention to stretching

Knitted fabrics are generally not suitable for the use of pushing back, pulling ironing skills modeling, but the use of the elasticity of the fabric itself or the appropriate use of pleating techniques to fit the body curve.

The size of the fabric stretch becomes an important basis in the sample design and production.

The sample of woven garments, the final area required to wrap the body is generally larger compared to the human body, that is, a certain amount of slack relative to the human body.

And knitted garments according to the use of different fabric structure, if the elasticity of the fabric is particularly large (with the use of yarn and tissue structure) when designing the sample not only does not leave the amount of slack, its sample size can be the same as the human circumference size, but also can consider the elasticity factor and reduce its size.

Pay attention to the thickness

There are knitted fabrics are usually thicker than woven (summer), so most of the layers of knitted fabric can not do too much, otherwise the stop is too thick, there are pressed folds, playing the finished process such as woven chiffon effect is not as good.

Attention to division

Since knitting in general has the characteristics of four-sided elasticity, it is easier to twist and distort when turning the pattern, so the knitted style should not be too complicated. When designing a pattern, you can minimize the number of seams, pleats, splices, etc. that are designed for modeling.

Especially not too many divisions, one because the characteristics of the knitted models is smooth, clean, too many divisions will be too complex, destroying the characteristics of the knitted models.

The second is to increase the difficulty of the car version, increasing the risk of large goods, and the cost of a single product increases.

Attention to the rolled edge

The rolled edge of the knitted fabric is caused by the disappearance of the stress in the coil at the edge of the fabric, and the edge of the fabric wrapped in the phenomenon. So the rolled edge is the deficiency of knitted fabric.

It can cause unevenness at the seam of the garment piece or the size change of the garment edge, which eventually affects the overall modeling effect of the garment and the specification size of the garment.

But not all knitted fabrics have rolled edge, for the rolled edge of the fabric, in the sample design can be put through the size of the edge, inlaid ribbing or rolled edge, or in the garment edge parts inlaid adhesive lining strip solution.

Some knitted fabrics with rolled edges can be eliminated in the process of finishing the fabric to avoid the trouble of sample design.

However, many designers in understanding the performance of the fabric on the basis of, can be the opposite of harm to benefit, the use of fabric rolled edge, will be designed in the sample of the collar, cuffs, so that the garment to get a special appearance of style.

Pay attention to dispersion

Knitted fabrics are different from woven fabrics in style and characteristics, and the style of the garment should not only emphasize the advantages of the fabric, but also overcome its shortcomings.

For example, the knitted fabric above has a dispersion, so the sample design and production should be careful not to use too many exaggerated techniques of division, as far as possible not to design provincial channels, cutting lines, and not too many stitching seams.