Introduction

Over the years, the fusion of fashion and technology has grown increasingly symbiotic, paving the way for groundbreaking advancements in smart textiles. This new era of textile innovation is revolutionizing the industry and transforming the way we think about clothing and wearable technology.

As we face various pain points in the fashion industry, innovative fabrics present themselves as hopeful alternatives to tackle these challenges. By embracing the potential of technology-infused textiles, we can create a brighter and more sustainable future for the fashion industry.

Innovative fabrics addressing pain points

A. Comfort and functionality: Temperature-regulating materials, such as phase-change materials (PCMs) and fabrics with moisture-wicking properties, enhance overall comfort and functionality.

B. Sustainability and environmental concerns: Eco-friendly textiles, like recycled polyester and biodegradable fabrics, as well as self-cleaning fabrics, can reduce the environmental impact of the fashion industry.

C. Personalization and user experience: Conductive fabrics with embedded sensors and electronics enable the creation of interactive and personalized smart clothing experiences.

D. Performance optimization in athletic wear: Fabrics with compression technology, moisture management, and biometric monitoring capabilities can help athletes enhance their performance and optimize recovery times.

E. Healthcare and medical applications: Textiles with antimicrobial properties or those that can monitor vital signs can provide valuable data for patients and healthcare providers.

F. Protective gear and military applications: Advanced materials like Kevlar and fabrics with built-in sensors can be employed in protective gear, offering increased durability, protection, and functionality.

History of technology in textiles

A. The marriage of technology and textiles dates back to the early innovations in fabric production, such as the Jacquard loom and the invention of synthetic fibers. These early technological advancements set the stage for more sophisticated and integrated applications in the fashion world.

B. As wearable technology emerged, we saw the birth of e-textiles, a groundbreaking development that brought the worlds of fashion and technology even closer.

Advancements in technology-infused textiles

The world of textiles has witnessed a remarkable transformation as groundbreaking technological advances continue to reshape the industry. These innovations are revolutionizing the way we think about apparel, enhancing the user experience, and meeting the diverse needs of consumers. These advances are paving the way for a more sustainable, practical and personalized future for the fashion world.

Conductive fabrics. Integrating conductive fibers, such as silver or copper, into fabrics opens up vast horizons for wearable technology. These materials enable seamless connectivity and communication, allowing for the creation of interactive and personalized clothing experiences. As these conductive fabrics continue to evolve, we can expect to see more innovative applications in fashion, healthcare, sports and more.

Temperature regulating materials. Comfort is paramount in the fashion world, and temperature-regulating materials have emerged as a breakthrough solution to this challenge. By utilizing phase change materials (PCM) and moisture-wicking technologies, these fabrics can maintain optimal body temperature for the wearer and adapt to a variety of environmental conditions. As the demand for comfortable and functional garments grows, thermoregulatory materials are expected to play an important role in the future of textiles.

Biometric monitoring textiles. The incorporation of biometric sensors into textiles opens up a new world of possibilities for fitness enthusiasts and healthcare professionals. By monitoring vital signs such as heart rate, body temperature, and even muscle activity, these textiles provide real-time data that can inform and optimize health management and athletic performance. As concerns about health and wellness continue to rise, biometric monitoring textiles are likely to become increasingly popular and widely adopted.

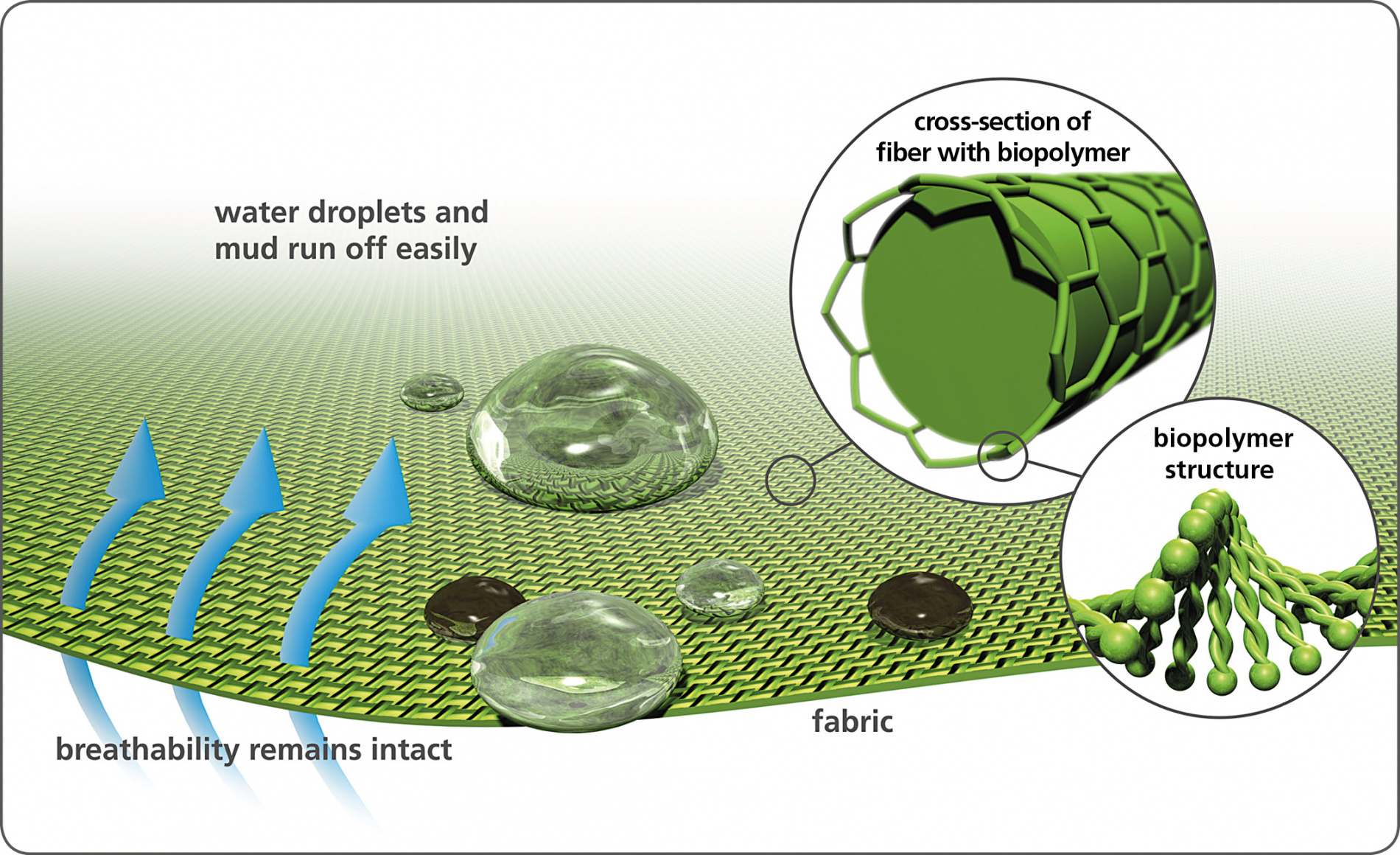

Self-healing and self-cleaning textiles. One of the most exciting advances in technology-infused textiles is the development of self-healing and self-cleaning materials. These innovative fabrics utilize a variety of technologies, such as microcapsules containing detergents or hydrophobic coatings, to extend the life of garments and reduce maintenance efforts. In addition to their practical benefits, these fabrics also have the potential to significantly reduce the environmental impact of the fashion industry by minimizing waste and water consumption.

3D printed textiles. The advent of 3D printing technology has already made its mark on the fashion industry, enabling the creation of complex, customizable garments. By using advanced materials and precise printing techniques, designers can create garments with unique structures and textures that were previously unattainable through traditional methods. As 3D printing technology becomes more accessible and cost-effective, we can expect to see a surge in the use of this innovative technology in the textile industry.

All in all, the advancement of textiles infused with technology holds great promise for the future of fashion. As we continue to explore and embrace these innovative materials, we can expect to see a more sustainable, functional and personalized world of apparel that meets the diverse needs of consumers and has a positive impact on the environment.

Sustainability and eco-friendly textiles in fashion

A. Sustainable fashion brands are now using innovative fabrics made from recycled materials, such as plastic bottles and old fishing nets, that are transformed into high-quality textiles with a stylish look and feel.

B. Fashion companies are incorporating digital tools and software to optimize their supply chain and reduce waste. For example, some brands are using AI-powered algorithms to forecast demand and prevent overproduction, while others are using blockchain technology to track the origin of their materials and ensure transparency.

C. A growing number of fashion brands are adopting circular business models, such as rental and resale programs, where clothes are kept in use for longer periods of time, reducing the need for new production. Others are investing in closed-loop manufacturing processes, where waste is minimized, and materials are recycled or reused at the end of their life cycle.

The future of technology-infused textiles

A. As fashion technology continues to evolve, we can expect even more groundbreaking trends and developments, reshaping the textile industry and the way we interact with clothing.

B. Consumer behavior is bound to shift as these innovations become mainstream, with an emphasis on personalization, functionality, and sustainability.

C. Challenges and opportunities lie ahead for the smart textile industry, as it navigates the complexities of bringing these innovative materials to market and integrating them into our everyday lives.

Conclusion

A. Technology-infused textiles have the power to transform the fashion industry and revolutionize the way we think about clothing and wearable technology.

B. By embracing this future and harnessing the potential of these innovations, we can create a more sustainable, functional, and personalized world of fashion.