For example, how to solve the problem when the difference between the board fabric, the big goods and the color card is too far? What standard can I refer to? What should I do if the size of the goods and the sample are different? Not sure about the shrinkage rate of the fabric, the design of the style may also go wrong? And so on.

Basic knowledge before buying

1. all fabrics will have more or less defects, not only short yardage, but also may have color difference, weft slant, cloth edge wave, etc., only the degree is very big or very small.

2. wear and tear is the production of clothes must add loss, depending on the type of cloth, clothing form, layout level, etc..

3.shrinkage is 3-4%, that is, the shrinkage rate of the fabric is the fabric in the washing or water immersion, the fabric shrinkage percentage, in the production of clothes to add the shrinkage rate into, lest the clothes shrink after the water.

4.material and tissue structure is not necessarily related, a variety of materials can basically do knitting or woven. Knitting or woven is the organizational structure, and does not refer to the material.

What to pay attention to when buying cloth

1. First, ask about the material and range, and the grade of the goods.

2. When receiving the goods, open it to see.

When inspecting the goods, watch the luster and brightness of the fabric, the dyeing condition, the surface thickness and the appearance characteristics of the tissue, grain and fiber, the softness, smoothness, thickness and elasticity of the fabric and fiber.

How to determine whether the fabric is “genuine”

1. The raw materials used, such as wool, where is the origin? South Africa wool? Merino wool? Or domestic wool? How about the number of wool?

2. treatment process, is there anything special about the raw material treatment process? For example, mercerization? Or anti-shrink? Or is it dyed with loose wool?

3. Yarn count/strand, 80 counts or 60 counts? The finer the yarn (the higher the count) the higher the price.

4. Weaving technology, here involves the machine needle type, spinning rate, table output.

5.finishing technology, is it dyeing or printing or just do under the feel? Printing is digital or reactive, etc

Short yardage and empty difference

Price error fabric purchase, there will be short yardage and empty difference, generally buy woven fabric will appear short yardage, knitted fabric will appear empty difference and paper tube.

1. Short yardage is less than the number of meters charged the full meter of money.

Fabric short yardage calculation standards: according to the standard is woven fabric + / – 2%, knitted + / – 3%.

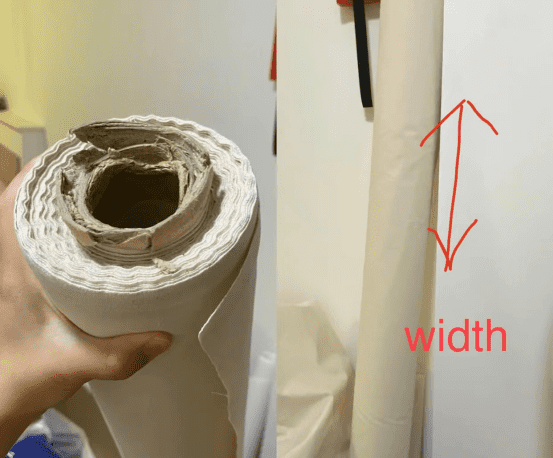

2. empty difference and paper tube only for the fabric bought by the pound, and is the kind of roll.

Paper tube as the name implies is a roll of fabric with a paper tube in the center, while the empty difference is the center of the paper tube is not.

When the fabric with paper tube is weighed, it is basically de-weighted, but it has no effect on the number of meters if there is no paper tube.

About the fabric warp and weft direction

1. If the fabric being identified has a cloth edge, the direction of the yarn parallel to the cloth edge is the warp direction, and the other side is the weft direction.

2. If the yarn twist of the fabric is different at the same time, most of the yarn with larger twist is warp direction, and the one with smaller twist is weft direction.

3. towel fabric, the direction of the yarn of the terry is the warp direction, not the terry is the weft direction.

leno fabrics, the direction of the yarn with twist is warp, the direction of the yarn without twist is weft.

5. In the interweaving of different raw materials (probability):

In general cotton-wool or cotton-linen interwoven fabrics, cotton is the warp yarn.

In wool-silk interwoven fabrics, silk is the warp yarn.

in wool-silk interwoven fabrics, then silk and cotton are the warp yarns

in natural silk and silk interwoven fabrics, the natural thread is the warp yarn

natural silk and rayon interwoven products, then the natural silk for warp yarn.

PS.

As a variety of fabrics are extremely versatile and many varieties, the requirements for fabric raw materials and organizational structure are also varied, so when judging, but also according to the specific circumstances of the woven products.

About judging the color difference in proofing

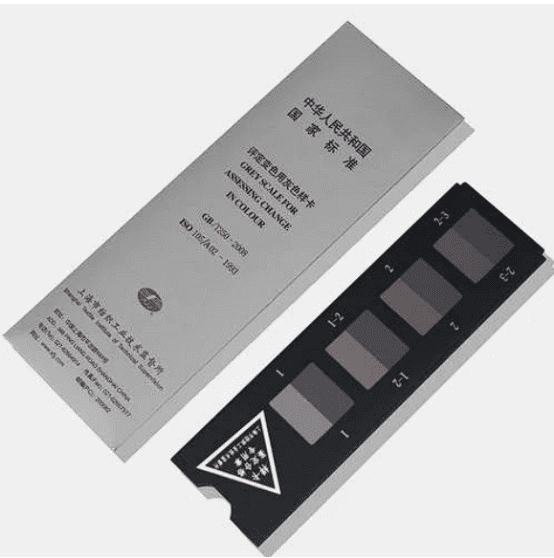

Generally, we use the “gray card” to see, the full name is “evaluate the gray card for color change” and “evaluate the gray card for color staining”, the color difference is generally used “evaluate the gray card for color change”.

The color fastness is evaluated by the “gray card for color staining”, which is divided into grades, 1 to 5, with 9 grades, that is, 1, 1~2, 2, 2~3, 3, 3~4, 4, 4~5, 5. No color difference is grade 5 (the best), and the worst is grade 1. In terms of knitted fabric, the general cut-off point is grade 3, above grade 3 is qualified products, below is substandard products, need to be returned for dyeing.

About the control of washing shrinkage rate

Before making the sample, the fabric should be washed and shrunk, ironed and shrunk by bonding machine, all of them should be tested, and the shrinkage rate should be calculated after the measurement.

Then the technician will add a certain shrinkage rate when making the sample, so that the size will be well controlled. Some parts of the clothes to be glued lining, naturally there must be shrinkage, so when making samples must take these details into account.

the general shrinkage rate of common fabrics

The smallest shrinkage rate is synthetic fibers and blended textiles.

Followed by woolen fabrics, linen fabrics.

Cotton fabrics in the middle.

Silk fabrics shrinkage is larger.

And the largest is viscose fiber, rayon, artificial wool fabrics.

Testing standards for textiles

There are color fastness, dimensional stability, appearance durability, tensile strength, tear strength, seam slip crack, pilling resistance, abrasion resistance, water repellency, water resistance, fabric density, yarn count, gram quality, etc.

About custom-made fabrics

Custom-made to have the amount, we must give the fabric factory enough time. Big stores, or offline brands can do so. A fabric type is tens of thousands, hundreds of thousands of meters, and some even buy their own blank, the cost is not you buy spot fabric comparable. Clothing is always the bigger the better to do, that’s true.

About the spot fabric (ready bulk)

Big goods and sample fabric is not the same, the first batch is not the same as the second batch, a roll of fabric less than three or five meters, are normal, look light on it. If the more expensive fabrics, or large quantities of orders, no matter how familiar the fabric merchant with you, the fabric must go to check the fabric.

No conditions to check the cloth, at least a few volumes of their own demolition of a meter a meter over again, found that the goods are not right, or have problems can also be returned. And so you on the cutting machine, even if it is indeed a fabric problem, you can not return.

About fabric purchasing volume

A piece of fabric several or even more than a dozen fabric merchants at the same time to sell too many cases. The price of each is still different. Good luck can directly find the manufacturer, even if you can not find the manufacturer, at least you can choose the lowest price.

About fabric merchant cooperation

Although many fabric merchants are “middlemen”, certainly to earn your money together. But if you do not share, let him earn a little. Cooperation for a long time will have many benefits. Help you find the urgent need of fabric, introduce other suppliers processing plant, give you the account period when the money is tight, help you return the problem to solve. In short, there are too many benefits, cooperation can be a win-win situation.

About fabric “middlemen”

Do the fabric is also divided, some families do everything, this is likely to be the “middleman”. Goods are not stable, problems are difficult to solve for you. Specializing in one or two kinds of much better, generally have a fixed manufacturer behind. For example, specializing in corduroy, his goods and full and stable, common problems are also clear. Accessories are actually the same. The more you do a certain type of single, the more professional you are.

Do not be afraid of trouble

Easy to shrink and easy to lose color fabric, each batch of fabric over to re-test the shrinkage rate and color fastness. Each batch may have differences. If you keep going by the result of the first test, it is likely to be a big problem. For example, the first batch of fabric from the same fabric merchant is a 9-point pant, but the second batch of shrinkage may become an 8-point pant directly.

About testing

As a brand and e-commerce, like wool cashmere silk these are high-risk materials. If it’s your own main promotion, remember to spend some money to do the composition test. It can be said that some fabric merchants give you inaccurate composition. 30% wool with you say 50%, 90% with you say 100% …… They are fine anyway, but do brand, e-commerce if the complaints reported that is a big deal.

About exceptionally low quotes

Sometimes you will encounter a particularly low offer from a certain company when you go to purchase fabrics, so low that you think you have a big bargain. Remember not to be impulsive at this time, there may be fabric problems in this case. In many cases, the fabric merchant will sell the fabric cheaply only when the goods are ordered by other families, but there is a problem and they don’t want it. There is too much shrinkage, or serious color loss. This must be cut back to test the sample. Do not impulsively order goods, often more losses than gains.

About delivery time

Some fabrics are in stock, while some need to order, these are what you have to consider. It is very irresponsible for a mature designer not to consider these things and dump the pot to the company buyer. Many designers are always very emotional, even capricious, only care about the immediate future, not the long term, as long as they like the fabric, do not ask the price regardless of the delivery date, regardless of whether it has the goods first take the color card and say. This is a very naive designer’s approach.