Introduction

Sourcing fabrics is an essential aspect of the textile industry. Businesses need to choose reliable suppliers that offer high-quality materials at reasonable prices to remain competitive. In recent years, some companies have turned to other countries in East Asia for fabric sourcing. like Vietnam Bangladesh and so on. While these countries offer lower labor costs, there are significant drawbacks to sourcing fabrics from them. This article examines why China remains the most unbeatable option for businesses looking to source fabrics in 2025.

The Importance of Sourcing Fabrics

Sourcing the right fabric is crucial for apparel development, especially in the competitive world of fashion. The fabric used can greatly impact the final product, including its overall appearance and quality. It’s important to work with a reliable fabric wholesaler who understands your business needs to ensure that you are sourcing the best fabric for your products and maximizing your profits.

When developing special clothing pieces, such as jackets, dresses, or suits, a large quantity of materials is needed, including fabric for the front and back sides, buttons, labels, and other related accessories.

Sourcing all materials from one country even in one city can save a lot of time and energy, especially in the fast-paced environment of the fashion industry. This approach can streamline the supply chain and ensure that all materials are compatible with each other, reducing the risk of inconsistencies in the final product. In a fast fashion business environment, time is of the essence, and sourcing materials from one place can help to speed up the production process and ensure that products are delivered to market quickly. Additionally, it can simplify the procurement process, reducing the administrative burden on the business and freeing up resources to focus on other areas of the business.

China’s Textile Industry: Scale and Infrastructure

China is the largest textile producer globally, accounting for over 40% of global production. China has been the world’s top textile exporter, churning out over 20 billion pieces in 2020 – over half of textiles in the world.The country has invested heavily in its textile industry, building world-class production facilities and transportation networks. China’s textile industry can handle high volumes of fabric production, which makes it an ideal option for businesses that need to source large quantities of fabric.

Whole Apparel Costs lower than Other Neighboring Countries

China’s textile industry is also known for its cost-effectiveness. Compared to other neighboring countries, the overall cost of producing apparel in China is relatively lower. This is due to China’s advanced production capabilities and its ability to produce fabrics and apparel in large quantities. Additionally, the country has a well-established supply chain that allows for efficient sourcing of materials and distribution of finished products. As a result, businesses can save money on production costs when sourcing materials and manufacturing apparel in China..

Diversified Fabric Options in China

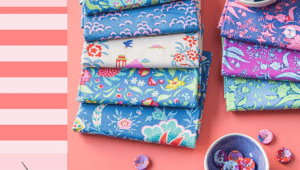

China’s textile industry is highly diversified, offering a wide range of fabrics, including luxury and high-end fabrics that are difficult to source in other countries. China has a long history of textile production and has developed expertise in producing a range of fabrics. Businesses looking to source specialized fabrics can find them in China, making it an unbeatable option for sourcing fabrics.

China has several main production areas for different types of fabrics, including Xinjiang for cotton, Shandong for cotton, Jiangsu for polyester, and Huzhou for silk. Regardless of the fabric material needed, it is possible to source it from China within two days due to the country’s efficient transportation network and supply chain. This rapid sourcing capability is a significant advantage for businesses that manufacture apparel in China, as it allows for faster turnaround times and increased efficiency in the production process.

Experience and Support of Chinese Suppliers

The reform and opening up policy started in 1970,China has opened its doors to the world and seen significant growth in its textile industry. As a result, many textile factories have emerged and gained valuable experience in manufacturing for top world fashion brands. China’s textile industry has developed advanced production capabilities, with the ability to produce high-quality fabrics and supply them in large quantities. This has made China a leading supplier of textiles globally, with the capacity to meet the demands of businesses around the world.

China’s textile industry has been a top global manufacturer for over 40 years. With advanced production capabilities and a vast array of fabric options, China has become a leading supplier of textiles to businesses around the world. The country’s experience and expertise in textile manufacturing have contributed to its success as a top textile manufacturer globally.

Challenges of Sourcing Fabrics from Other Countries

Sourcing fabrics from other countries in East Asia can be challenging. While labor costs may be lower, there are other factors to consider, such as shipping costs and lead times. Countries like Vietnam and Cambodia lack the scale and infrastructure of China’s textile industry, which can lead to longer lead times and higher costs in the long run. Additionally, language barriers and cultural differences can also pose challenges when dealing with suppliers from other countries.

It’s true that sourcing textiles from countries other than developing countries can be a good choice for brands, as long as they meet the required fabric couring standards. However, it’s important to note that each country in East Asia may have its limitations. Despite this, China remains the best one-stop solution for world fashion brands due to its capabilities in meeting various requirements.

Conclusion

In recent years, there has been a trend towards sourcing fabrics from other countries in East Asia, such as Vietnam and Cambodia. While these countries offer lower labor costs, they lack the scale and infrastructure of China’s textile industry, which can lead to longer lead times and higher costs in the long run.

Moreover, China’s industry is highly diversified and offers a wide range of fabrics, including luxury and high-end fabrics that are difficult to source in other countries. Chinese suppliers also have a wealth of experience in the industry and can offer advice and support to businesses looking to source fabrics.

Overall, while there may be other options available in East Asia for fabric sourcing, China remains the most unbeatable option for businesses looking to source fabrics till to 2025.