Chinese Clothing print industry Development

clothing printing mainly refers to t-shirts, sweatshirts, casual clothing, knitted sportswear, children’s clothing, denim clothing, jumpers, individual pattern prints on garments or garments, but also knitted underwear, home wear, women’s clothing continuous pattern printing. The majority of fabrics are cotton weft knitted fabrics, while functional, modified and cotton- and linen-like polyester fabrics are gradually being […]

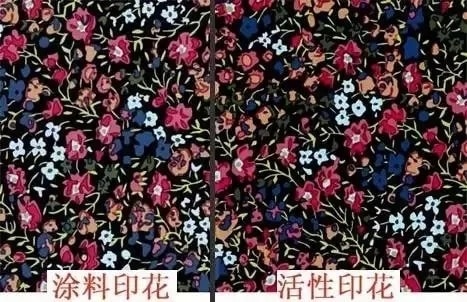

printing processes commonly used on textile fabrics

Textile fabric pearlescent and luminous printing There are natural and artificial pearlescent, and artificial pearlescent can be extracted from fish scales. Pearlescent does not need to be stimulated by light sources and is resistant to acids and alkalis and high temperatures. Tencel fabrics with pearlescent printing show a soft pearl-like lustre and elegance, with an […]

Coatings in digital inkjet printers

The traditional printing methods used in printing and dyeing industry are reactive dyes, disperse dyes, acid dyes and coating direct printing; among them, reactive dyes, disperse dyes and acid dyes printing are commonly used by the majority of printing and dyeing manufacturers because of their printing patterns with bright colors, full colors, soft fabric feel and clear pattern outline; many foreign trade orders also add some special requirements, such as chlorine bleaching resistance, oxygen bleaching resistance, dry cleaning resistance, etc.. Therefore, we must use the latest technical means to adapt to the requirements of the market, otherwise a very passive situation will be formed and the development of the industry will be hindered. In this case, people will naturally think of non-polluting or less polluting printing method a coating printing.

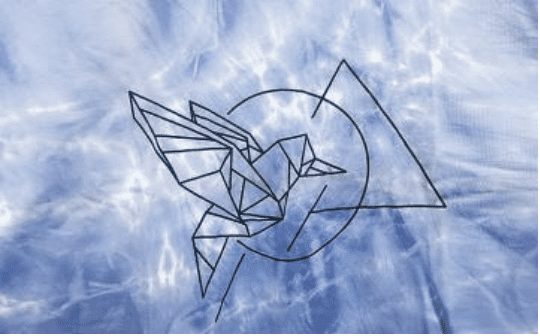

The combination of digital printing and tie-dye

In order to combine the traditional Chinese tie-dye technique with digital printing technology for textile and clothing, and to design modern digital printing patterns that match the corresponding characteristics of tie-dye, the advantages, disadvantages and the need to combine tie-dye and digital printing are analysed. The advantages, disadvantages and necessity of combining tie-dye and digital printing at this stage are analysed, as well as the significance and development prospects of combining the two techniques. The innovative combination of digital printing and traditional tie-dye techniques is used in apparel, home textiles and fabrics. This combination will, to a certain extent, open up a new aesthetic market and promote the development of digital printing and traditional tie-dye techniques, providing a reference for innovative product development.

The development of China’s printing industry

The 30-year development process of China’s printing technology has seen a second leap forward, with frequent technical activities contributing to the technological progress of the printing industry. The article presents a few forward-looking thoughts on the development of fabrics, digital rod-ink printing and special printing.

Adaptability of digital ink on fabrics

Heat transfer inks are a key element in the field of heat transfer technology. In order for heat transfer technology to be compatible with different fabrics, the rheological and printing adaptability of the inks applied to the surface of the paper base must be studied. The transfer of inks that can be transferred to chemical and natural fibre fabrics onto transfer paper and then onto the corresponding fabric. The rheological properties of the thermal transfer inks were analysed and the relationship between the ink and the printability was determined by measuring the ink density and the transfer paper.

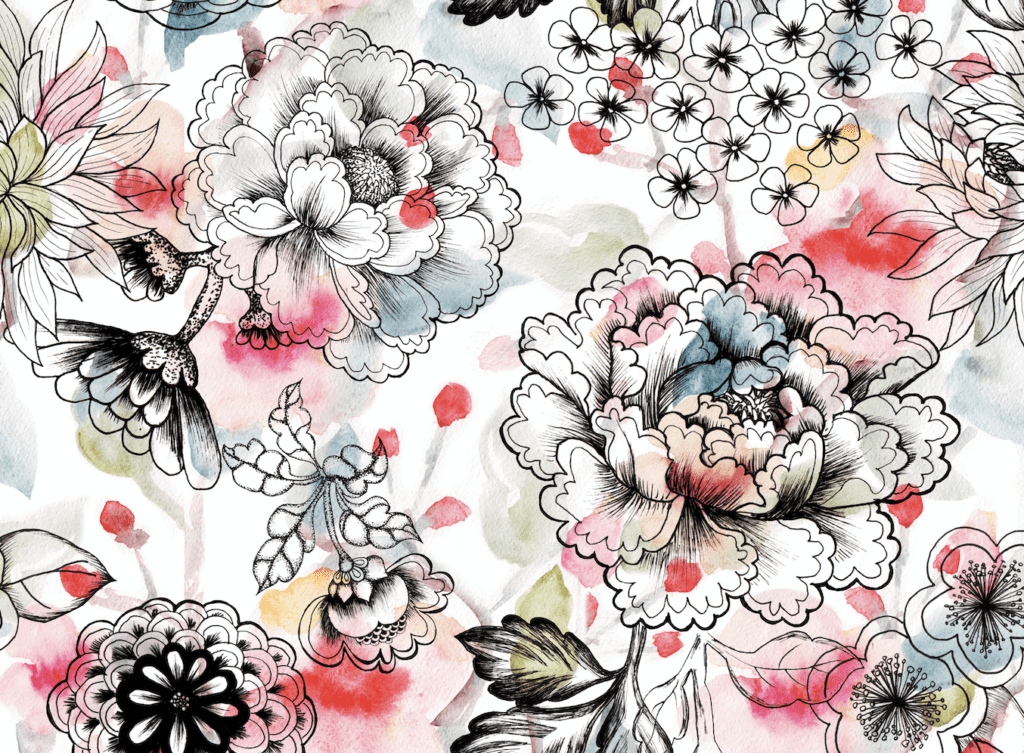

Innovation of digital patterns in clothing

The emergence of digital printing has provided a new way of thinking for textile fabric printing and has contributed to the rapid development of digital inkjet printing in textile fabric printing. This paper summarises the theory of digital printing technology and examines the innovative application of digital printing in garment design.

Acid Ink Application in Printing

The digital transfer printing technology and equipment is now available everywhere, and the market for nylon fabric printing mainly uses screen printing, cold transfer printing, digital direct spray printing and several other methods. Flat or circular screen printing is difficult for complex and delicate colour patterns, and there is a lot of effluent in the printing process. Cold transfer printing, which involves wetting the fabric and transferring it at room temperature, is sensitive to the degree of wetness of the fabric during the transfer process and once the degree of wetness changes during the transfer process, the colour difference is often intolerable. Digital direct-jet printing is the direction in which industry colleagues are working. This is done by ink-jet printing acidic inks on sized fabrics, followed by steam evaporation and washing and drying.

Digital Printing Addresses Quality Needs and Environmental Concerns

The textile printing market is rapidly going digital and is receiving great attention. Because this is a world in high demand for digital printing, printing can also become pictures of local Chinese producers, and the number is not large. In addition, digital printing can greatly increase water consumption, so many companies use digital printing technology to recycle digital Printing Technology.

Factors affecting ink and color

Textile digital printing is developing rapidly in China, many textile digital printing machine manufacturers are transformed from the advertising industry, but textile printing is very different from advertising printing, machine manufacturers lack printing and dyeing technology, and many machines are difficult to sell. The ink of digital printing is different from dyes, and there are more factors affecting the quality of textile digital fabrics than traditional printing, which will also bring difficulties to the promotion of ink.