Tactile sensation of fabrics

The tactile sensation of fabric refers to the feeling of human skin when it touches the fabric

Such as smooth, rough; weak, scraping; smooth, board astringent; active, dull; rigid, soft; fluffy, knotted; thick, thin; rich, loose; warm, cool, etc.

The fabric’s sense of touch and fabric composition of a variety of factors related to.

Such as different raw materials have different tactile sensations, silk smooth, hemp coarse and hard, etc..

The same raw material different yarn fabric has different tactile sensation, low cotton fabric rough, high cotton fabric fine and clean, etc.

Different warp and weft density of fabrics have different tactile sensations, high density fabrics are hard and stiff, sparse fabrics are weak, etc.

Different fabric tissues have different tactile sensations, satin fabric smooth, plain fabric flat and so on.

Different finishing processes have different tactile sensations, such as smooth and soft liquid ammonia finishing, rich and glutinous smooth hair type loose finishing, etc.

The feel of the fabric

The feel of the fabric refers to the feel of the hand to identify certain physical properties of the fabric, is an important aspect of the style.

Different fabrics have different feel, such as thick tweed, imitation wool fabric requires a rich, thick feel, while the thin woolen fabrics such as vanadine, cool tweed requires a smooth, crisp feel.

Factors affecting the feel of the fabric are fiber raw materials, yarn fineness and twist, fabric organization and dyeing and finishing process. Among them, the fiber raw materials have a greater impact, the fiber rules feel soft, the fiber is straight feel smooth. Yarn twist is appropriate, the fabric feel both soft and cool; twist is too large, the fabric feel hard; twist is too small, the fabric feel soft.

The feel is also related to certain mechanical properties of the fabric, such as fabric flexibility, extensibility, resilience, etc.

Flexibility indicates that the fabric is easy to bend the performance or stiffness.

Extensibility indicates the degree of fabric stretching deformation.

resilience indicates the degree of fabric deformation recovery.

Surface heat transfer coefficient and heat transfer rate reflect the fabric coolness or warmth.

Fabric feel reflects the appearance and comfort of the fabric in different degrees.

The rigidity and flexibility of the fabric

The rigidity and flexibility of the fabric refers to the ability of the fabric to resist the bending stress, also known as the bending stiffness.

The greater the bending stiffness, the more rigid the fabric. The appropriate bending stiffness indicates that the fabric is stiff.

The bending stiffness of the fabric is related to the nature of the fabric raw material, the thickness of the fabric fiber, the density of the fabric and other factors.

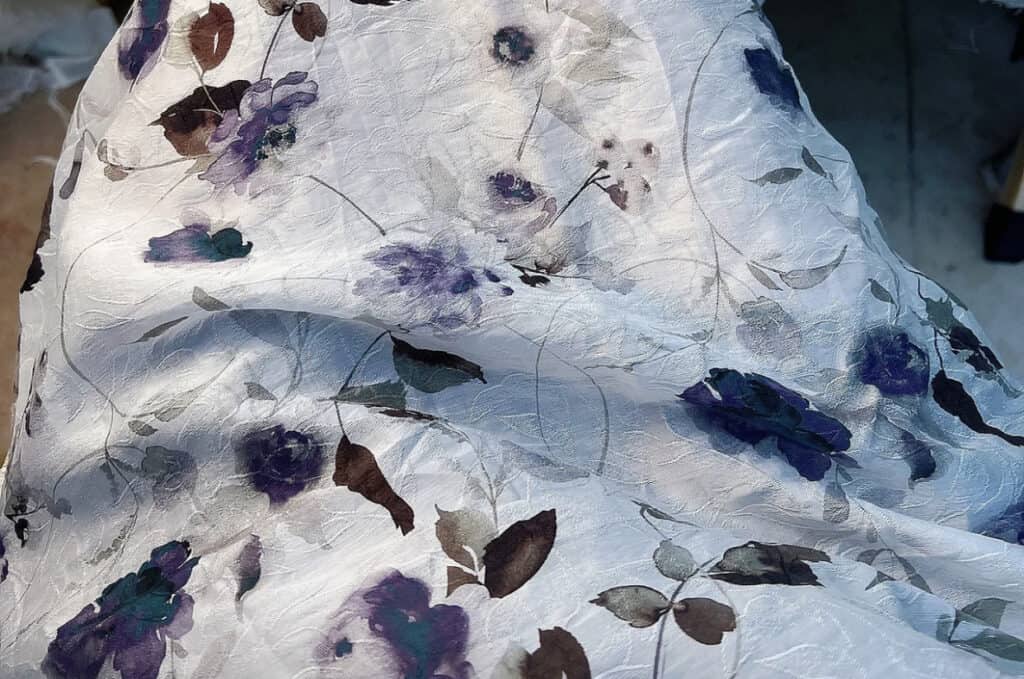

Drape of fabric

Drape of fabric refers to the property of forming smooth and even curvature surface under natural drape of fabric. The softer the fabric, the better the drapability.

Drape is the performance of the performance of soft clothing style must be, such as the hem of the flared skirt, the shape of the hanging wave and the shape of loose clothing, etc., all need drape good fabric.

Drapability and just flexible, bending stiffness of the fabric drapability is poor. The fabric with fine fiber and loose organization has better drapability.