Articulationes in digital inkjet impressores

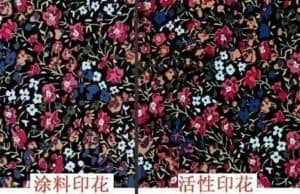

Traditum methodi typographicae adhibitae industriae imprimendi et tingendi sunt tingui reciproci, tingui dispergendi, tingui acidorum et recta imprimendi vestiendi; apud eos, colores reactivos, colores reactivos, tingui ac tincturas acidas typographicas dispergunt, vulgo a plerisque fabricatoribus typographicis et tingendis adhibiti sunt ob exemplaria imprimendi cum splendido colore, colore pleno, mollis fabricae sentiendi et perspicui exemplaris adumbratae; plures ordines commercii externi nonnullas etiam speciales exigentias addunt, ut resistentia inficit, oxygenium inficit, resistentia purgans arida, resistentia purganda etc. Oportet igitur utendum ultimis instrumentis technicis ad exigentias mercatus accommodare, alias condicionem valde passivam. formabitur et industria impedietur. Hoc in casu, homines naturaliter cogitant de methodo imprimendi non polluendi vel minus polluendi imprimendi tunicam.