analysis-of-print-fabric-examination

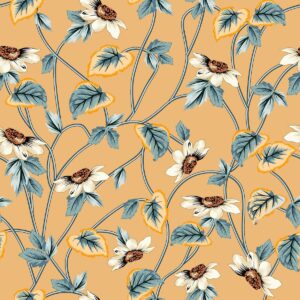

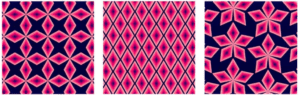

The number of printed fabric products in China’s design landscape is large, but there are currently some misconceptions about the examination of such products. The current method of submitting images also has limitations for the fast-growing category of printed products. This paper analyses these misconceptions and limitations, both in terms of the printing process and design, in order to explore ways to better protect such products in the future.