The problem of creasing (cockle marks)

Knitted fabric boiling bleaching and dyeing processing are generally carried out in the overflow cylinder, the entire processing process of the fabric are kept in rope state, fiber in the dyeing machine constantly bending deformation, the original hydrogen bond is constantly destroyed, new hydrogen bond constantly formed, sometimes the newly formed hydrogen bond can not be completely back, so in the fabric surface to form chicken claw marks, dead crease.

In the single-sided fabric structure, the tension of the yarn on both sides is asymmetrical, and it is difficult for the fabric to return after a long one-way crease, so the various structures are more prone to the problem of fine wrinkles with plain, jersey, single bead ground, etc. The younger the yarn count and the higher the twist, the greater the possibility of reverse untwisting of the yarn, which is reflected on the surface of the fabric as a problem of fine wrinkles.

5 Preventive measures

Depending on the conditions under which they are formed, improvements are made mainly in the following areas.

Predetermined type

Through the predetermined type to improve the proximity and orientation of the fibres, the fabric by heat setting when the fibre microstructure and morphology changes, the fabric is fully stretched when setting and set under the action of high temperature, the fibre morphology is fixed, reducing the chances of change in the dyeing bath and helping to reduce creases.

Elimination of internal stress before falling into the cylinder

Loose cloth is fully relaxed in the stacking truck after loosening, the grey cloth is generally kept in the warehouse, and the relative humidity in the warehouse is low, the cloth is stacked together for a long time in a very dry state, it is easy to produce indentations, after loosening the cloth should be placed in a place with high humidity in the workshop to fully rehumidify, the fibres undergo a certain dissolution when rehumidifying, the internal stress is partially eliminated.

elimination by J-slotting, after loosening the cloth and letting it pass freely through the J-slot, while the original hydrogen bonding is changed through compression roller extrusion or roller drawing, which is conducive to the elimination of internal stresses.

Reduction of creases by flat stretching and superheated water. Knitted blanks are generally cylindrical and can be fully stretched by means of guide rings, while spraying wet steam or superheated water troughs to reduce creases, and a certain penetrating and smoothing agent can be added to make the cloth fully wet when superheated.

Boiling and dyeing

Pay attention to the capacity of the dyeing tank, the dyeing should generally be reduced by 10-15% in accordance with the provisions of the dyeing tank, do not overload the operation, when the amount of cloth is too large, the fabric in the storage tank is seriously pressurised, at the nozzle can not be stretched, it is easy to form pressure marks; pay attention to the rate of temperature rise and fall, when the rate of temperature rise or fall is too fast, the temperature of the cloth body is easy to produce uneven, concentrated in the fibres at one point, the fibres are different degrees of cold and heat, shrinkage is uneven, especially When the temperature is lowered, it is easy to be cold in the local area and the plastic fibre form is solidified, forming wrinkles that are difficult to eliminate. So after the high temperature process, generally at a rate of 1 to 1.5/min cool down to 70 ℃ drainage, or after the high temperature process first directly into the cold water overflow, to be completely drained after the temperature is reduced.

Adding lubricants to the dye bath to reduce friction between fabrics and between fabrics and machinery, thereby reducing the chance of creasing, but the choice of smoothing agent needs to take into account issues such as stability and compatibility with the processing process to avoid other problems arising from improper choice of lubricant.

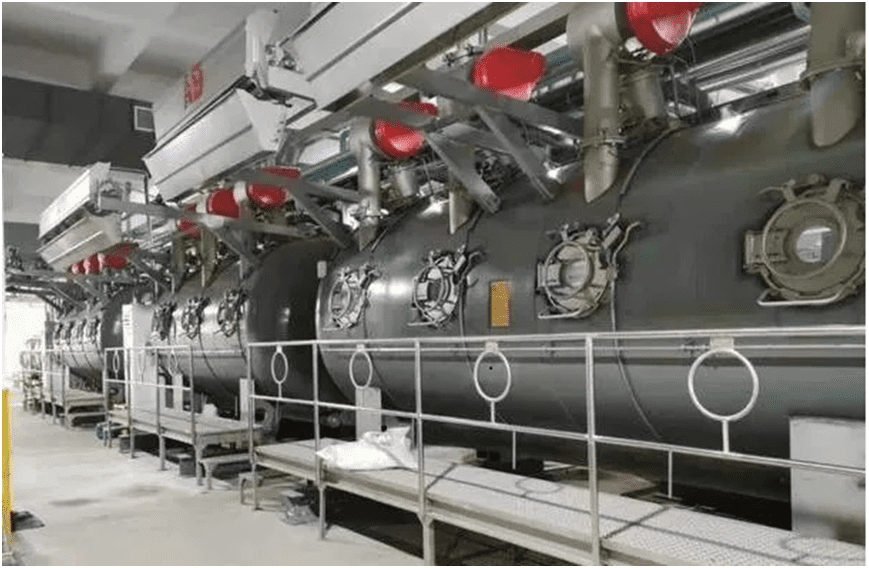

Choose more advanced machinery, increase the width of the storage tank, reduce the height of the lifting roller are conducive to reducing the pressure on the fabric body, the choice of airflow cylinder, the fabric in the nozzle by high pressure gas fully blown away, the fiber from the tension state to get a “rest”, conducive to the elimination of internal stress.

Drying method

When the fabric is dried by dewatering, the fabric is dewatered in the high centrifugal force dewatering machine, and when the time is too long, it is easy to produce wrinkles that are difficult to eliminate. Many dyeing plants are gradually adopting the way of rolling water to dry the fabric in flat width, which improves the efficiency of drying the fabric and is also conducive to the solution of wrinkles. After water rolling, the cylindrical fabric can be dried by the shockwave machine after being stretched wide by the guide ring, and the open width fabric can be dried by the needle chain stretched wide.

Stacking method

The weight of the fabric car stacking fabric must not be too large, the time must not be too long, especially when the wet fabric is stored, out of the cylinder storage must not exceed 6 hours.

The problem is the result of the whole set of process, not by the addition of a kind of additives can be solved, with the fibre, with the fabric structure, with the processing technology, but also with the processing equipment, after the emergence of creases, generally lighter creases can be solved by shaping machine pulling wide shaped, stubborn can return to the tank wash, gradually heating up to 85 ℃, in the gradual cooling to 50 ℃ process test back to repair, or can be in the industrial throwing dry machine The dyeing plant can be reshaped according to their own equipment and creases