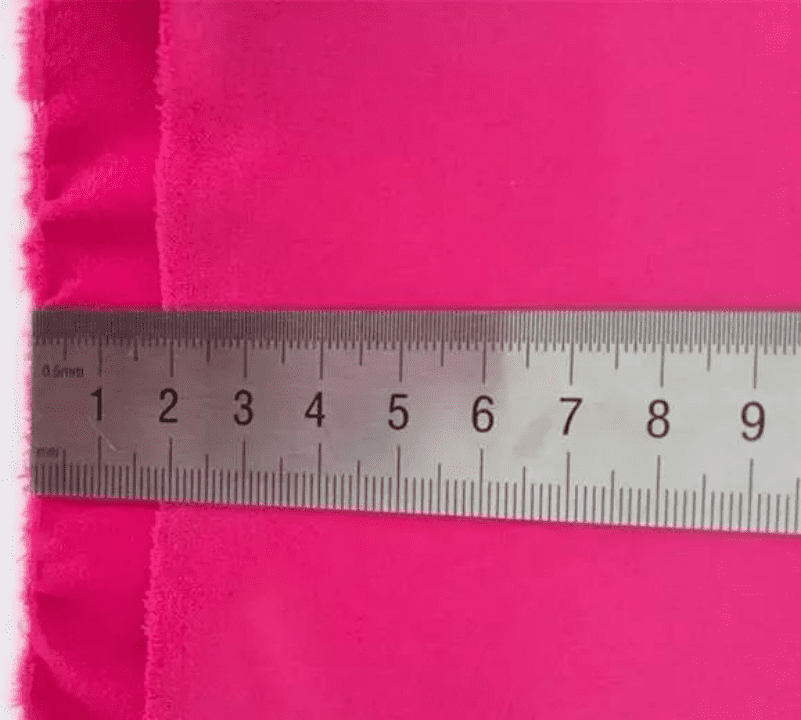

Measure the weft slope of woven fabrics

In the vertical state of the fabric, l find a balance line as a reference, align one end of it with the straight line, then measure the height of the balance line on the other side, and divide the high/(low) height by the width of the door width, which is the number of weft slope.

Tear off a piece by hand, and then aligned with the edge of the cloth folded, see the most difference of a few cm and then divided by the door width to get the percentage. This is difficult to say, depending on the style. Striped on the trouble, 5% below the basic is no problem, beyond this row of material to consider the left and right bone position uniform direction slant, to avoid twisting tube.

Control of weft skew.

According to the type of weft slant, different weft adjusters can be used. The principle of weft adjustment is to adjust the relative running speed between the warp yarns of the fabric through the mechanical action of the overall mechanism, so that the corresponding part of the weft slant is “ahead” or “behind”, thus restoring the weft yarn and warp yarn in The weft and warp yarns are restored to intersect vertically in the full width.

Reason of weft skew

Why do the fabric tissues of the fabric and the fabric fibers of the knitted fabric become tilted? Or the fabric tissue becomes twisted in a serpentine manner? This phenomenon is called weft slanting, and there are two reasons for it.

Reason 1: If the fabric design or knitted fabric design is not good, the weft slope will be formed. In this case, the design itself must be completely changed.

The second reason: Although the textile is made according to the normal textile and design, the weft slope is formed during the dyeing process and printing process. This kind of weft slanting accident happens in dyeing and printing factory mostly in short fiber fabric and filament fabric plain fabric. The reason is that the weft slope is easy to occur in the cloth dyed and washed in rope form. Because the softer the fabric is, the more easily the tissue is deformed. Therefore, if the rope dyeing or similar dyeing machine is used, the weft slanting of plain fabrics is particularly significant, and the weft slanting and snaking (S-shaped) state of the fabrics are easily formed.

When bending produces defective products, the textile (dip-dyeing, continuous dyeing, printing) using the fabric will all become defective if the fabric’s tissue is bent. Especially in the case of printing finishing, the bending state is obvious at a glance. When weft-skewed fabrics are used for printing and finishing, the result is a “bending” accident. The printing pattern is bent to the fabric. If the guide tape for squeegee of circular screen printing machine or automatic flat screen printing machine is stuck together with the fabric that is not finished, it will cause weft bending.

Solution of weft slope

(1) Comparing the weft slope dimensions of the above two pictures, it is easy to see that the weft slope of the latter has improved significantly. In order to solve this problem, the cloth is corrected by passing the cloth slanting rod in front of the regulator and creating a tension difference on each side of the cloth. In addition, there are many factories where the weft slope of the cloth is corrected by hand and the regulator is placed by the snake side. However, this method cannot completely eliminate the weft slope. There are many factories like this.

Complete solution

(2) In the case of correcting the weft slope and snaking of the cloth by the visual inspection and manual operation of the regulator, there is a risk of weft slope or snaking of the cloth instantly if the visual inspection and manual operation are wrong. The way to prevent weft slope completely is to install a weft slope correction device (weft straightener) in front of the regulator or in front of the printing machine, and if the cloth is allowed to pass through this device, the weft slope can be eliminated. If the three interconnected devices (weft correction device) of sensor, microprocessor and specially designed guide are used, it is possible to correct weft in an unmanned way.