Yarn source defects

1.The yarn material should have good colour absorption. Yellow and white yarns and dark crosses are not acceptable, and defects such as dead cotton/hair grains/yarn shells are not acceptable.

2.Red and blue dots; flying flowers; nylon grass; knotted ends; thick knots etc. must not exceed 15 times/bolt. Defects must not exceed 0.5cm in length and must be removed if they are removable. Exceeding this limit: one yard of full fabric cover per/each untreatable defect is deducted according to the corresponding yard weight.

Weaving defects

1.No obvious stitch paths, needle paths or oil stitches.

2.No more than 2 yards/bolt of leaking stitches, flower stitches, rotten stitches or broken yarn.

3.No more than 2 bolts/bolt of embroidered fabric.

4.Spandex type elastic fabric (stretch fabric) is not acceptable with loose stretch, uneven drop stretch, stretch out of position, broken stretch and other defects, and may not exceed 3 yards/bolt.

5.Do not accept defects such as central marks, creases, scratches or wind marks on the embryo fabric.

6.We do not accept fabrics with serious linting due to yarn material.

Printing and dyeing defects and related requirements

1.Dyed flowers (including stripes/clouds/segments), shaded colours and large bolt differences are not acceptable.

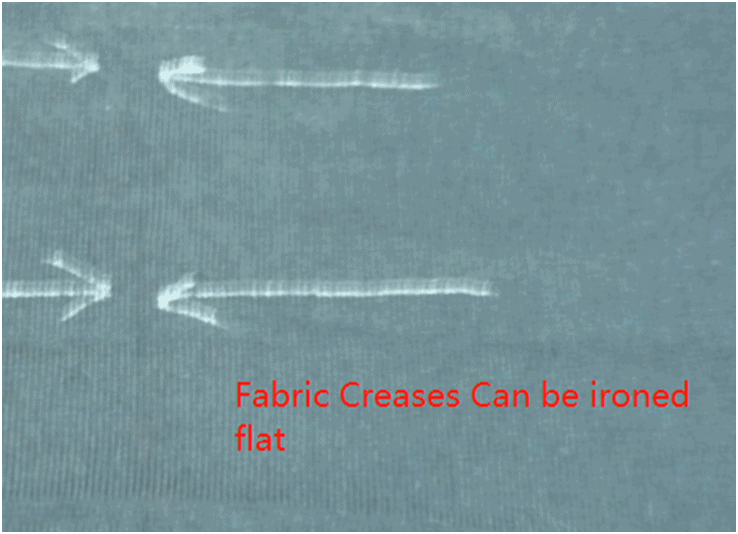

2.No flaws in the folds of paragraphs or full bolts are accepted, and the folds must not be painted with a colour pen. Obvious creases must not exceed 3 yards per bolt.

3.No defects such as soft oil stains, floating colours, lipstick marks, bamboo leaf marks, alkali spots, mould spots, rust stains (dots), pigment stains (dots), etc.

4.Each bolt of fabric must not have more than 2 cut out rows or barges; stains, oil spots and other removable defects must be removed before delivery.

5. Do not accept the phenomenon of large (bad) hair on the surface of the cloth, and require the surface of the cloth to be smooth and clean. We will take into account the treatment of the head of hair on the repaired cloth.

6.Grasping and brushing cloths: do not accept obvious brushing marks, broken yarns, unevenness in the degree of velvet on the edges, etc., and the degree of velvet should be identified with the full.

6.Printing with cloth dyeing can not fall soft oil (or choose printing specified soft oil) plucking printing with cloth bottom dyeing must choose plucking printing specified pigment.

8.Print leakage (sandy bottom) must be completed before delivery. Cloth body has a yin and Yang colour and bolt difference need to indicate the corresponding bolt number in the delivery sheet and on the bolt of cloth on the mark, so that the clothing according to the corresponding mark bolt cutting or positioning cutting with.

Specification finishing requirements

1. Utility cover

Le “practical fabric seal” refers to the effective width that can be cut after removing the selvedge or needle rows, rotten edges, etc. The error of the open edge shaping class is within (-1〃~+1.5〃) and is regarded as qualified. (The test of 12 hours of placing the fabric in the same bolt of fabric is subject to).

2. Unit grammage (Gm/m²)

The error of ordinary open edge shaping class is within ±4%; the test after the delivery of the finished product is within ±5% for plain/unit clothes/pearl ground as qualified (the test placed for 12 hours shall prevail).

3. Fabric pattern

1.Double-sided fabric, printing, stripes, plaid and other face fabric weft slope ≤ 3%, considered qualified (except for double-sided fabric with needle draw).

2.One-sided fabric, solid-coloured fabric and lining fabric with weft slope ≤ 4% shall be regarded as qualified. When there is a conflict between twist and slope, try to reduce the slope under the premise of ensuring the twist.

3.Inter-strip cycle error: any 5 cycles of total spacing error within 3% qualified, any 5 cycles of total spacing error between the same cloth in 2% qualified.

4.Regardless of straight and oblique grain, the grain should be straight, no wavy grain, seven-letter grain, etc. is acceptable. The blistering of the fabric surface after shaping is not acceptable.

4. Fabric surface and feel

The effect of the dyed fabric and the feel of the fabric will be according to the sample confirmed by both parties. The fabric must be soft and smooth when there are no special requirements.

Testing requirements

1. Shrinkage rate: the national first class standard of conformity shall prevail.

1).Shrinkage is tested by hanging to dry.

2).General fabric straight shrinkage within (-5%-±1.5%), horizontal shrinkage within ((-5.5%-±1.5%) accepted.

3).The twist of the fabric after washing must be within ±4%.

2. Colour fastness: the national first-class qualified standard shall prevail.

1).Washing colour fastness in light colours above grade 4, dark colours above grade 3.5.

2).Dry rubbing fastness in light colours above grade 4, dark colours above grade 3.5; wet rubbing fastness in light colours above grade 4, dark colours above grade 3, brushed hairs above grade 2.5.

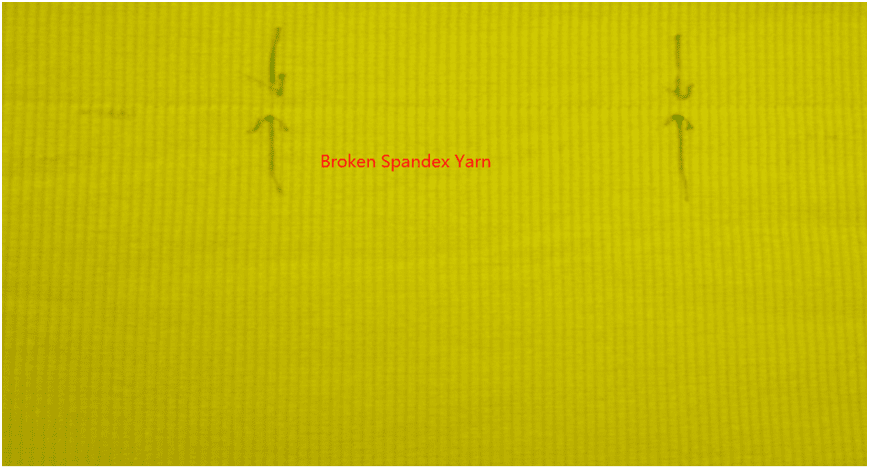

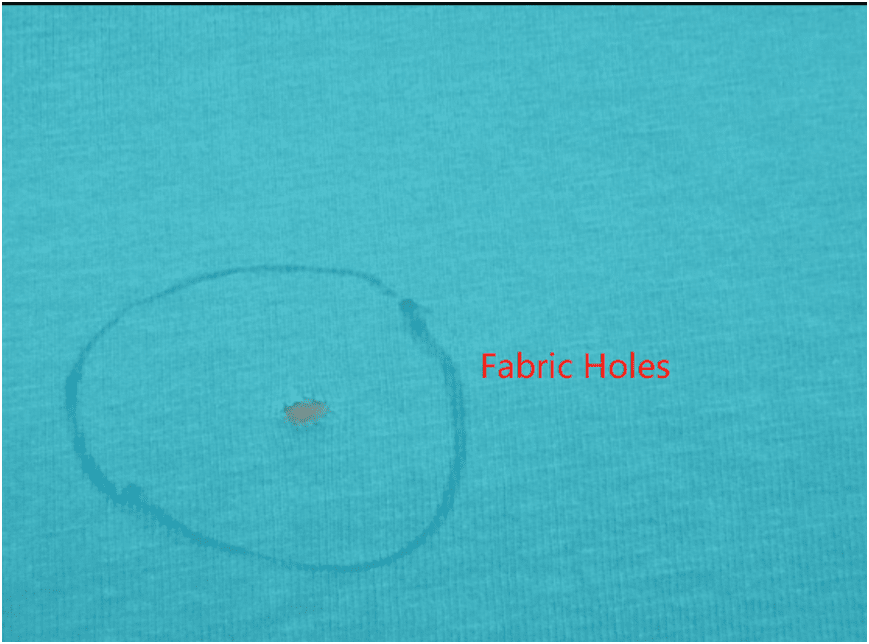

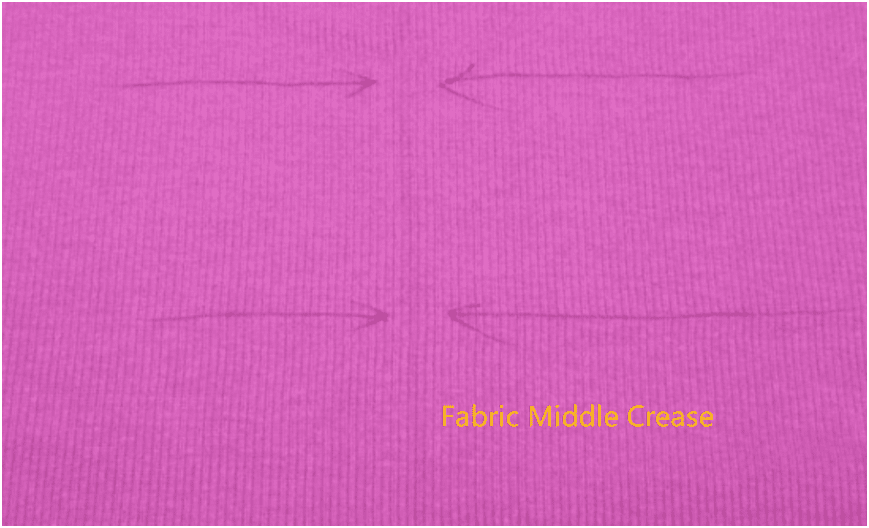

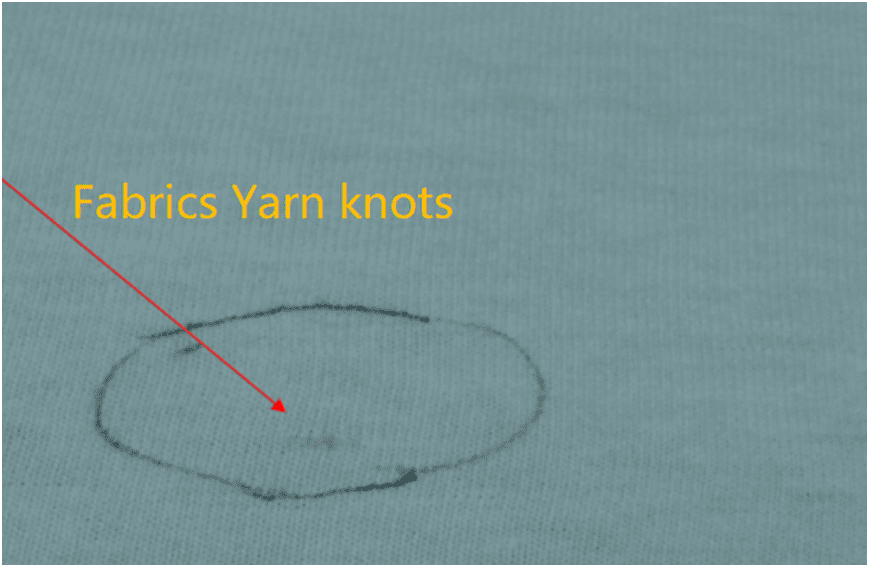

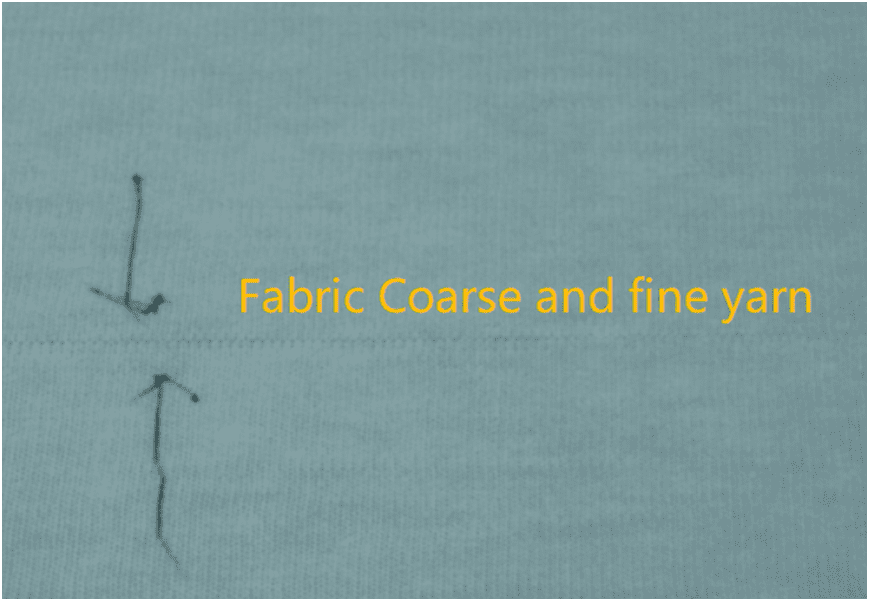

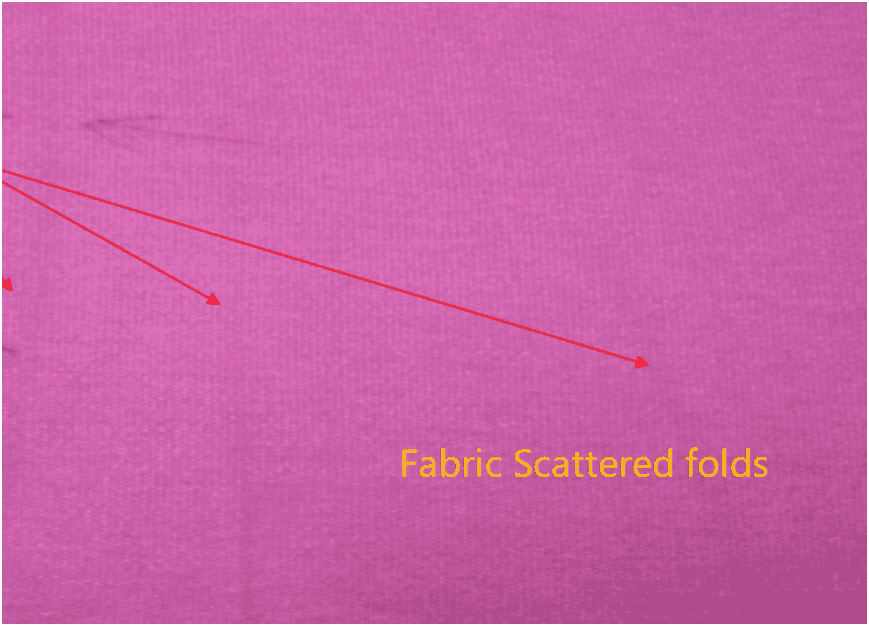

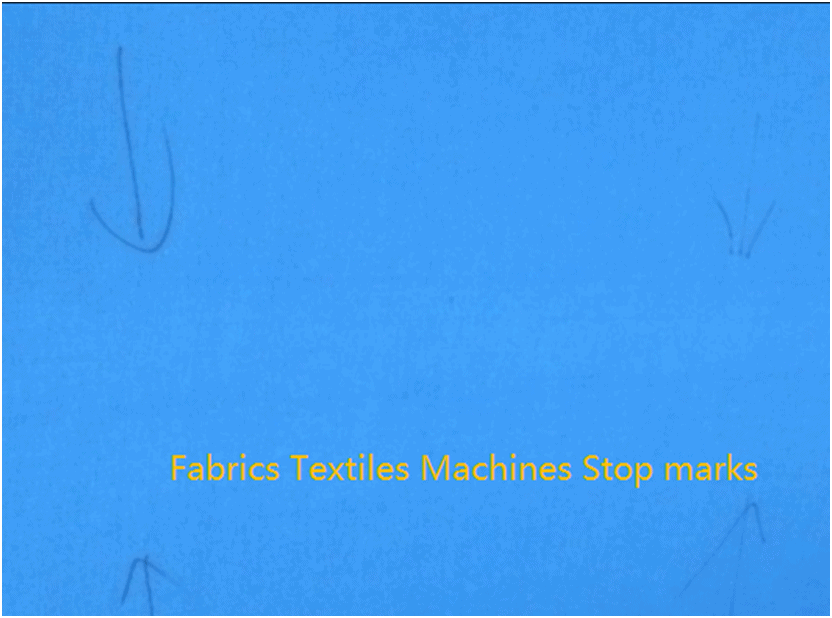

15 Fabric defect photo demonstration

Broken Spandex Yarn

Fabric Ragged stitches

Fabric Holes

Fabric Middle Crease

Fabrics Yarn knots

Fabric Coarse and fine yarn

Fabric Scattered folds

Fabrics Textiles Machines Stop marks

Fabric Severe colour fibre

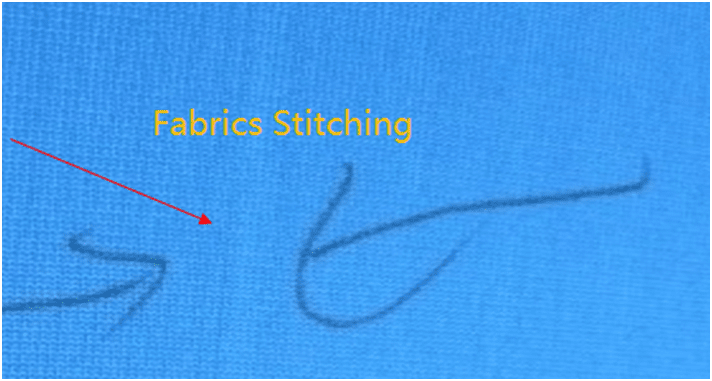

Fabrics Stitching

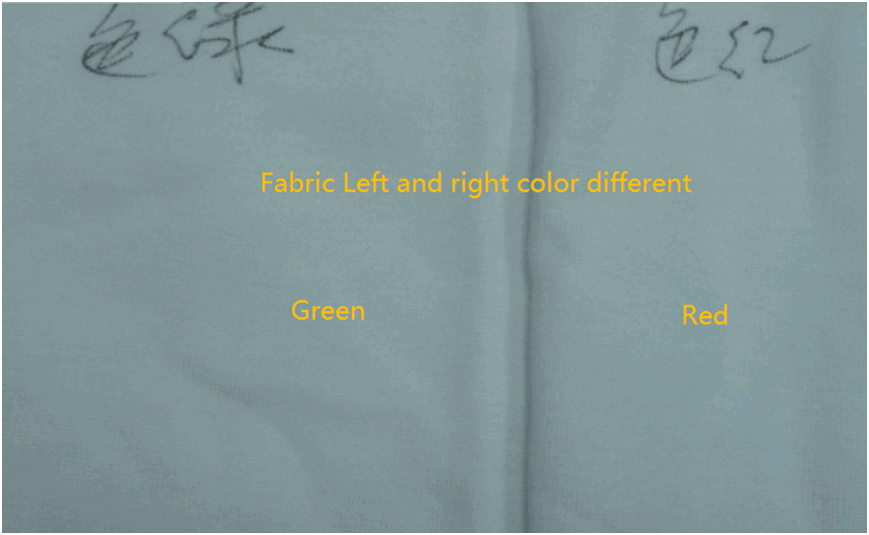

Fabric Left and right color different

Fabric Scuffs

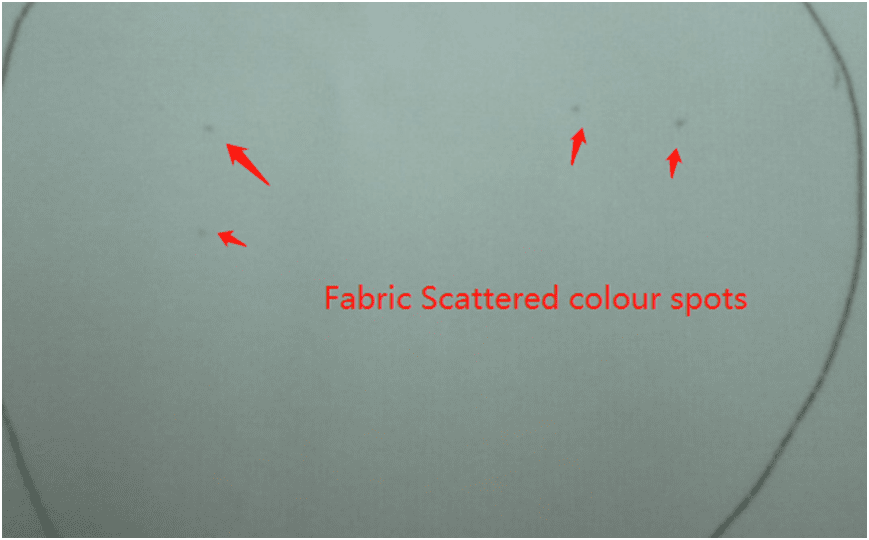

Fabric Scattered colour spots

Fabric Creases Can be ironed flat

Slightly coloured fibre