Cost of raw materials

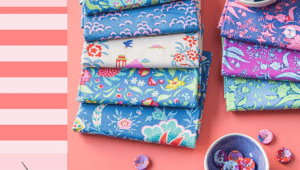

Raw material cost = yarn quantity per meter x yarn price

How to calculate the amount of yarn used per meter? We divide all fabrics into non-stretch fabrics, weft stretch fabrics and four-sided stretch fabrics to explain separately.

1 Fabric without elasticity

The warp density of grey fabric = finished warp density × finished width / grey fabric width The sample fabric or specification given to us by the customer is mostly the finished product, which has been dyed.

Weft density of grey fabric = weft density of finished product × (1- dyeing shrinkage)

Note: Dyeing shrinkage, about 2-5% of cotton, 3-8% of polyester-cotton, 8-15% of polyester, the thinner the cloth the greater the dyeing shrinkage, machine cylinder dyeing than long car dyeing shrinkage to be greater, the smaller the finished fabric steam shrinkage requirements, the greater the dyeing shrinkage.

Let’s give an example, for example, the conventional varieties of cotton sarong blank specifications are 21s × 16s/128 × 60 width 63 inches (note that the specifications of the yarn count unit are British count count, the density of the unit are inches, the unit of width is also inches, some specifications are not this unit, can be converted over, for example, the unit of chemical fiber is D, then the number of D × British count = 5314, when the number of D 150, converted to inch count = 5314/150 = 35.4 (branches)

Formula.

The amount of warp yarn = (warp density × door width × 0.65) / warp yarn count, that is, 128 × 63 × 0.65 / 21 = 249.6 grams

Weft yarn amount = (weft density × width × 0.65) / weft yarn count

i.e. 60×63×0.65/16 = 153.6g

Where.

0.65 is a coefficient, a very rough one, and there are many factors affecting the size of this coefficient here, such as weaving shrinkage, elongation in the warp direction because of tension, loss, etc.

Here the amount of yarn used per meter of fabric is not equal to the finished fabric weight per meter, there is also a coefficient, generally with 0.88, we calculate the amount of yarn used is 249.6 + 153.6 = 403.2 g/m, the finished weight is about 403.2 × 0.88 = 355 g/m, square meter weight is 355/1.5 (door width) = 237g/m2, different fabrics this When dyeing, there are many factors that affect this coefficient, such as shrinkage, alkali reduction, pre-treatment, etc. Many times we have to rely on experience to summarize this coefficient.

Suppose the price of 21 counts of cotton yarn is 20,000 yuan/ton = 0.02 yuan/gram, then the cost of yarn used in warp direction is: 249.6×0.02=4.992 yuan/m; similarly, suppose the price of 16 counts of cotton yarn is 18,000 yuan/ton, then the cost of yarn used in weft direction is 153.6×0.018=2.76 yuan/m. The raw material cost of this specification is 4.992+2.76=7.75 yuan/m.

Some yarns are special, such as some bamboo yarns, yarns with special blending ratio, yarns for special purposes, which are not available on the market and need to be spun, the price is more expensive than regular yarns, which also affects the cost and delivery time.

2 Weft stretch fabrics

Conventional weft stretch fabrics are available in corresponding blanks, such as

Finished cotton stretch poplin.

40×40+40D/133×72 57/58 inches corresponding to the blank is 96×72 on the machine door width 84 inches

Finished cotton stretch sateen: 16×16

16×16+70D/120×40 48/50 inches corresponding to the blank is 90×40 on the machine door width 72 inches

Finished cotton elastic straight tribute products

32×32+40D/190×80 57/58 inches corresponding to the blank is 130×80 on the machine door width of 84 inches

The shrinkage rate of other weft fabrics that are not conventional is calculated according to this ratio, and the general shrinkage rate of the door width is about 30%.

3 Four-sided stretch fabric

The method is the same, also to the finished fabric specifications to reduce to the specifications of the blank fabric on the machine, and then calculated in accordance with the way no elasticity.

For example, cotton four-sided elastic, the finished specification is 32s/2 + 70D × 32s/2 + 70d density is 100 × 60/inch, the width is 46 inches, reduced to the machine specifications of the blank should be the density of 65 × 46 width is 72 inches, (weft shrinkage of 35%, warp shrinkage of 23%, generally long car tie-dye), according to the previous formula can be calculated using the amount of yarn. (65 + 46) × 72 × 0.65/16 = 325g/m (warp and weft yarn count is the same as the warp and weft density added together), that is, the amount of yarn per meter is 325 grams.

For example, the common finished product specification 200d+40d×200d+40 density is 118×80/inch, the width is 57/58, and the reduction into the machine specification of the blank should be 82×56 (all polyester four-sided elastic is generally dyed with overflow cylinder, the shrinkage rate is about 30% in both warp and weft), the width of the machine is 84 inches, 200d converted into count should be 5314/200=26.6 counts, according to the formula of yarn quantity: (82+56)×84×0.65/26.6=283g/m.

Other T / R four-sided elastic, T / C four-sided elastic, are the same reason, but the warp and weft shrinkage size is different, the specific shrinkage data to consult people with relevant production experience.

There are some special fabrics, such as warp grosgrain, high shrinkage fabric, wrinkle fabric, etc. I have less contact and no practical experience in this area.

According to the amount of yarn used in the blank fabric, and taking into account the warp shrinkage of dyeing, alkali reduction and other factors, we can roughly calculate the grammage of the finished product, this theoretical calculation of the grammage and the actual grammage varies greatly, the general error in plus or minus 20 grams / meter, can only be used as a reference.

Weaving cost

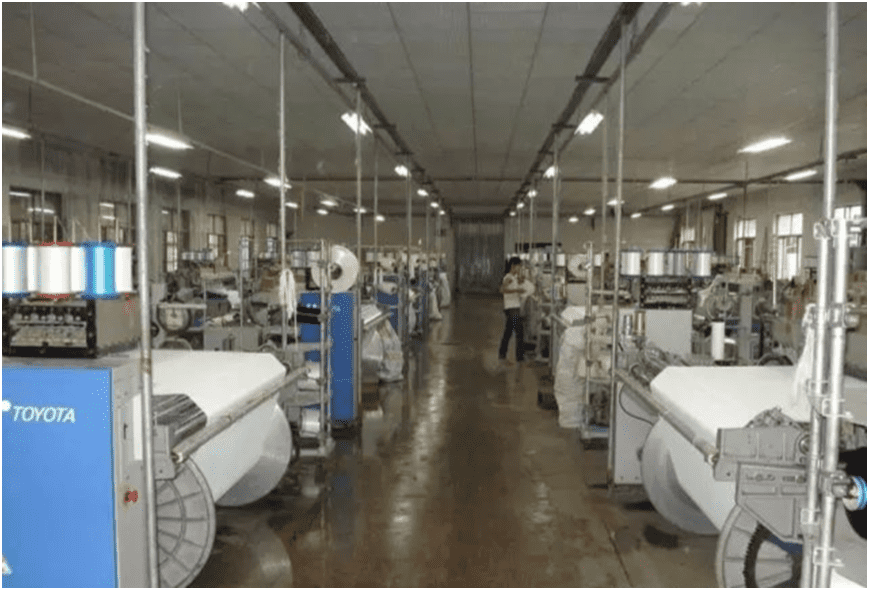

Weaving cost is mainly related to the weft density, followed by the loom.

For example, the general cotton with air-jet loom, usually said “10 cents a shuttle” that is: weft density divided by 2.54, and then multiplied by 0.1, is the weaving cost, such as conventional varieties of cotton poplin 40 × 40 133 × 72 / inch, the weft density is 72, the calculated weaving fee is 72/2.54 × 0.1 = 2.83 yuan / meter. If the full chemical fiber filament, without sizing, weaving costs can be calculated by 8 cents.

Some varieties are more difficult to weave, weaving fees and higher, the door width is larger, weaving fees and a little higher, the more high-grade loom, the more expensive weaving fees, with shuttle loom weaving fees are the cheapest, piece shuttle loom, large jacquard loom weaving fees are the most expensive.

The processing fee is cheaper in the off-season than in the peak season, the first half of the year is the off-season and the second half of the year is the peak season. Large factories, up-scale factories, factories with standardized management have some quality assurance compared to small factories, and processing fees are also more expensive, so choose the right factory according to the quality requirements of different customers.

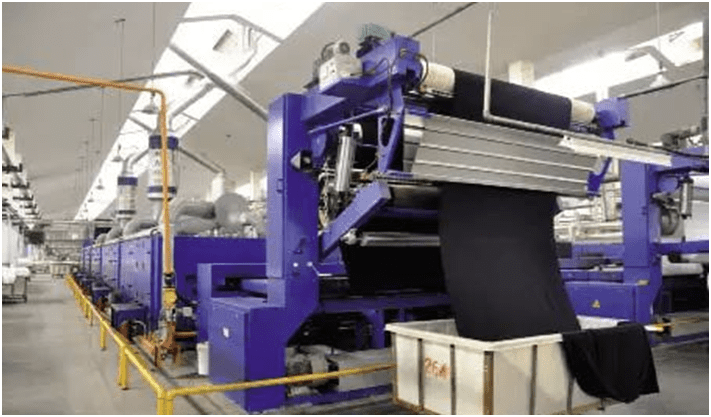

Dyeing and printing finishing processing fee

The dyeing cost of general cotton fabrics is about 1.5 yuan/meter for spring and summer fabrics and about 2.8 yuan for autumn and winter fabrics with long car tie-dyeing and full process active dyeing.

Ordinary all-polyester fabric dyed by machine cylinder, spring and summer fabrics at about 1 yuan/meter, autumn and winter fabrics at about 2 yuan.

The processing fee for ordinary printing varies from 2 yuan to 5 yuan according to several sets of colors and the width of the door width.

In short, the higher the quality requirement, the more expensive the corresponding processing fee.

While calculating these processing fees, don’t forget to count the shrinkage rate, plus the loss. For example, cotton four-sided elastic fabric, warp shrinkage rate of 23%, dyeing costs 4.5 yuan / m, if the blank is 15 yuan / m, then dyeing good cost is: 15 / (1 – 23%) + 4.5 = 23.98 yuan / m, plus the loss of 2% (the production process of sewing head, etc.), 23.98 × 1.02 = 24.46 yuan / m.

Other special fabrics, such as nylon fabrics, Tencel, Modal, etc., or special processing fees, such as Teflon three anti-treatment, embroidery processing fees, coating, composite, etc., need to consult the corresponding production and processing companies in detail to come up with the exact cost.

Other costs

The cost of inspection and packaging is generally 0.1 yuan/m, VAT is 17%, for example, the profit is 1 yuan/m, then to pay 0.17 yuan/m tax, if the guest does not need an invoice, generally can be cheaper by 3%.

It should be noted that the theoretical calculation here is only suitable for customized varieties and special specifications of fabrics. If it is a regular variety, the price on the market is generally cheaper than the theoretical price, the actual price has the market price, in the major textile website basically can be found, because the quantity is large, the processing cost of each link is cheap, the loss is small, there are some jerry-built production is cheaper, such as less than the gram weight, less than the warp and weft density, the yarn count is thin, the dyeing quality is not good, the yarn used is poor, the strength is not good, etc. The strength is not good, etc.