The concept of digital printed fabrics

Digital printed fabrics are precisely fabrics produced by computer-aided design, digital manufacturing and network technology, using printing processing equipment and production processes. The principle of this digital printing technology is to use digital means such as scanners, digital machines or the internet to input the desired pattern into the computer, then process it through a computerised colour separation printing system and have the professional RIP software print various dyes (reactive, disperse, acidic and other paints) directly onto the fabric through the printing system. This method produces fabrics with a high technological content, improves the precision of the print, allows positioning control of the position and size of the pattern on the garment, produces a colourful pattern, does not require plate making, has a wide colour range and produces little pollution.

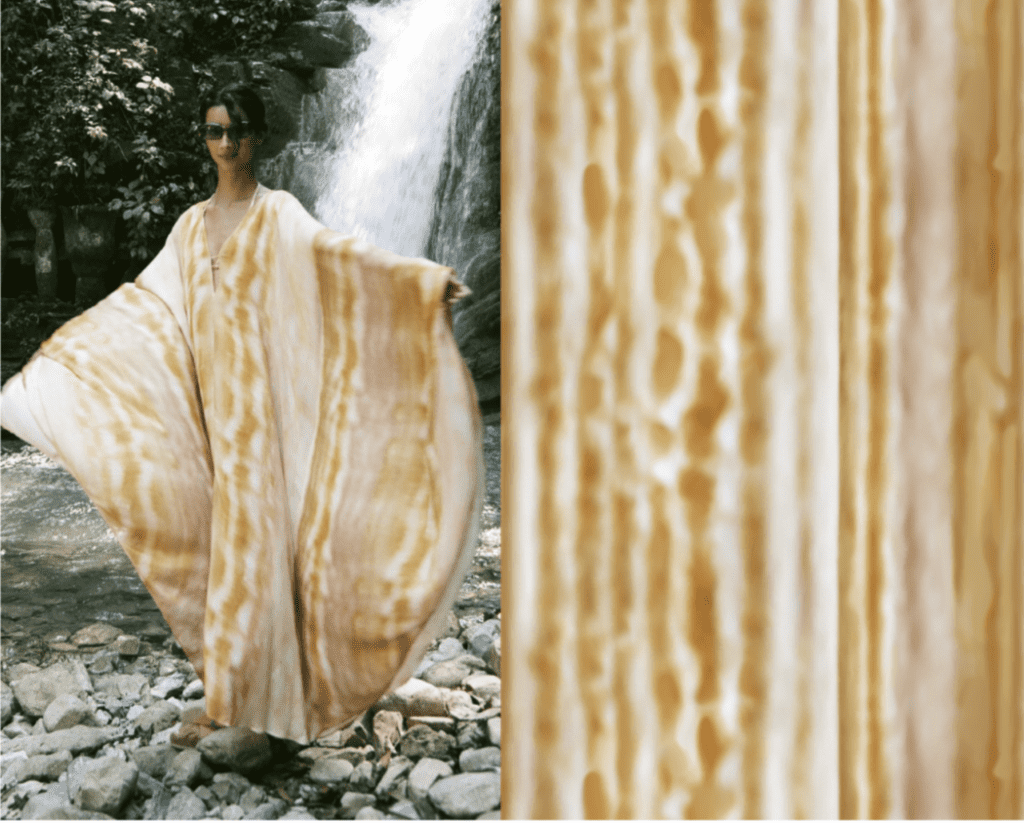

The combination of pattern design and digital technology has opened up a wide range of possibilities in the field of fabric and pattern design, allowing for the production of more personalised designs. The use of digital printing technology to apply traditional Chinese ink and landscape paintings to modern women’s clothing (Fig. 1) allows the pattern to be printed in a way that effectively controls the position and size of the landscape painting, and allows the gradual change in the intensity of the ink and wash of the painting to be fully printed out, better demonstrating the beauty of the ink and wash mood of the garment. This new printing technology has not only created a boom in the fabric industry, but has also inspired fashion designers. Designers are demanding not only the best colour saturation, but also more detailed variations between colours and, in some cases, photo-like clarity.

Fig. 1 Traditional ink painting in women’s clothing

Comparison of traditional printed fabrics and digital printed fabrics

Traditional printing is generally manual printing, flat screen printing, roller printing, direct printing, dyeing printing, anti-dyeing printing, anti-printing printing, special printing, coating printing 9 kinds of printing methods. The traditional printing technology mainly relies on the workers’ manual colour overprinting, due to the limitation of colour overlay technology, it is very difficult to print more than 10 sets of traditional printing, which also determines that the traditional printing technology is difficult to achieve more than 10 kinds of colour printing, which limits the variety and level of printing colours. The process is tedious, and it takes about 10 days for all the test prints to be proofed. As shown in Figures 2 and 3, the blue print is a traditional openwork version of white paste anti-dye printing, a masterpiece of traditional Chinese printing techniques. Engraving is more appropriate for well-defined patterns, where gradual colour changes are difficult to achieve naturally.

Applied Technology

Fig. 2 Openwork version of white paste anti-dye printing

Fig. 3 Openwork version of white paste anti-dye printing engraving

The digital printing process is computer controlled and the advantages of digitally printed fabrics compared to traditional printed fabrics are.

(1) Digital printing technology is able to achieve 16.7 million colours, breaking through the limitations of traditional printing, so digital printed fabrics have obvious advantages in terms of colour gradient levels, cloud patterns and other high-precision pattern effects.

Fig. 4 Digital printing with rich colour layers and high simulation accuracy effect

(2) The fabric design material can be derived from photographs, scanned patterns, etc., or digital patterns transformed by PHOTOSHOP, and the shape, size and colour of the printed fabric patterns can be used as desired in the design of the garment.

(3) By adjusting the dose of dye sprayed by the nozzles of the digital printing machine, the fabric can be partially formed in the pattern with concave and convex texture, resulting in fabric texture changes; moreover, there is no waste of water or dye in the production process and less pollution.

(4) Compared with the traditional printing fabric proofing time, digital technology fabric in the pattern design, through the U disk, CD, E-MAIL and other ways to transfer to the computer, through the colour test can be directly proofed, proofing time is generally within a day, is the traditional proofing efficiency of about 10 times. In the European printing industry, more than 90% of enterprises have adopted digital printing machines for proofing, and the industry generally believes that digital printing machines are fast, low cost and consistent, and digital printing has become an essential tool in the European printing industry.

(5) Traditional print patterns are often limited by the length of the pattern, but the digital printing process does not have the concept of length and width, so garment designers can design patterns according to their design ideas, which to a certain extent frees up design talent and improves the size and space of the fabric pattern, thus enhancing the quality and effect of the printed fabric. Digital printing technology has therefore significantly increased the richness of patterns and colours in printed fabrics, and has expanded the range of fabrics available to designers.

(6) The printing can be done on garment pieces, which can be well adapted to the printing requirements of small batches and many varieties of garments, so that one piece can really be printed and immediately available. This allows you to make the most of your individual design needs.

Design applications of digital printed fabrics in apparel

Modern designers need to pursue some new designs to meet the individual needs of their customers. With the use of digital printing fabrics, designers can design digital printing fabrics according to the needs of clothing design, allowing designers to have more freedom of imagination in pattern creation and colour change design, thus allowing clothing design to fly on the wings of imagination. The common applications of digital printing fabrics in garments can be divided into the following two methods.

Distribution of patterns in garments by digital print

(1) Overall application of digital printed fabrics

The use of the entire print fabric directly designed clothing, which mainly pay attention to some of the patterns between the stitching, large area of the print pattern is generally selected for the style is more on the simple, simple atmospheric silhouette with colorful prints, both simple

The overall use of digital print, as shown in Figure 5, from TRENDIANO Men’s Spring/Summer collection, is a dramatic use of black to create a new look for the pixelated floral print, adding a sense of rigour to the whole garment. The overall use of digital printing, as shown in Figure 5, is a dramatic black base colour for the pixelated floral pattern, adding a sense of rigour and making the whole plain looking T-shirt interesting due to the random variation of the pattern.

Fig. 5 Overall digital printing application Flavourfulness.

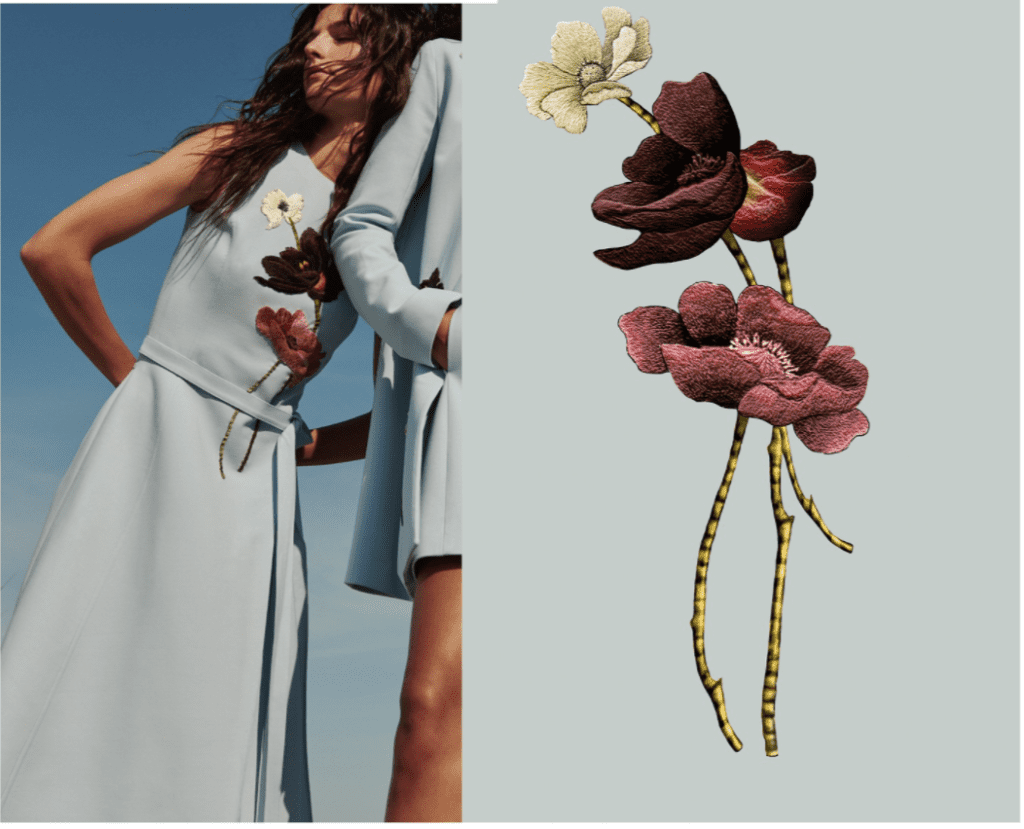

(2) Local application of digital printed fabrics

The print is positioned on a solid colour base on parts of the garment, such as the chest, sleeves, skirt etc. The print is mainly decorative and accentuates the design, highlighting the whole garment and the part. As shown in Figure 6, LouisVuitton’s Spring/Summer 2013 womenswear collection features a jumpy positioning print that revitalises and contrasts an otherwise monotonous style, and the yellow and grey colour positioning print on the upper garment echoes the colour and shape of the white positioning print on the summer garment, resulting in a more harmonious look.

Fig. 6 Local application of digital printing

(3) A variety of digital printing stitching applications

The combination of different printed fabrics is the highest level of contrast and harmonisation of lightness, purity and shade between the fabrics. The garments shown in Figure 7 are from the Dries Van Noten Autumn/Winter 2012 Haute Couture collection. The designer has flattened the kimono and dragon robe, photographed them and digitally printed them onto the fabric in a shredded way, stripping away their inner luxury and transforming them into accessible garments for ordinary people. The fragility of the kimono silk and the roughness of the army khaki or the robustness of the grey flannel are combined in a collage. The harmonisation of lightness, purity and shades of colour between the different fabrics makes the garments themselves more informative and intriguing in their details, thus creating a stronger sense of pleasure. Dries has used his talent to capture the sparkle of this clash.

Fig. 7 Digital print stitching application

The reason why digital printing is so popular with many designers is that it is a simple design that expresses a unique artistic effect and is simpler and less costly than designs that previously required more handwork. Digital printing is more in line with today’s demand for simplicity, individuality, fashion and unique detailing in clothing.

Ways of applying digital print fabrics in garment design

3.2.1 One application of digitally printed fabrics in garment design

In garment design, the more delicate and rich the digital print, the simpler the silhouette chosen for the garment, the more the contrast between the shape and colour of the print to reflect the changes in the garment. The use of small areas of fabric in the garment.

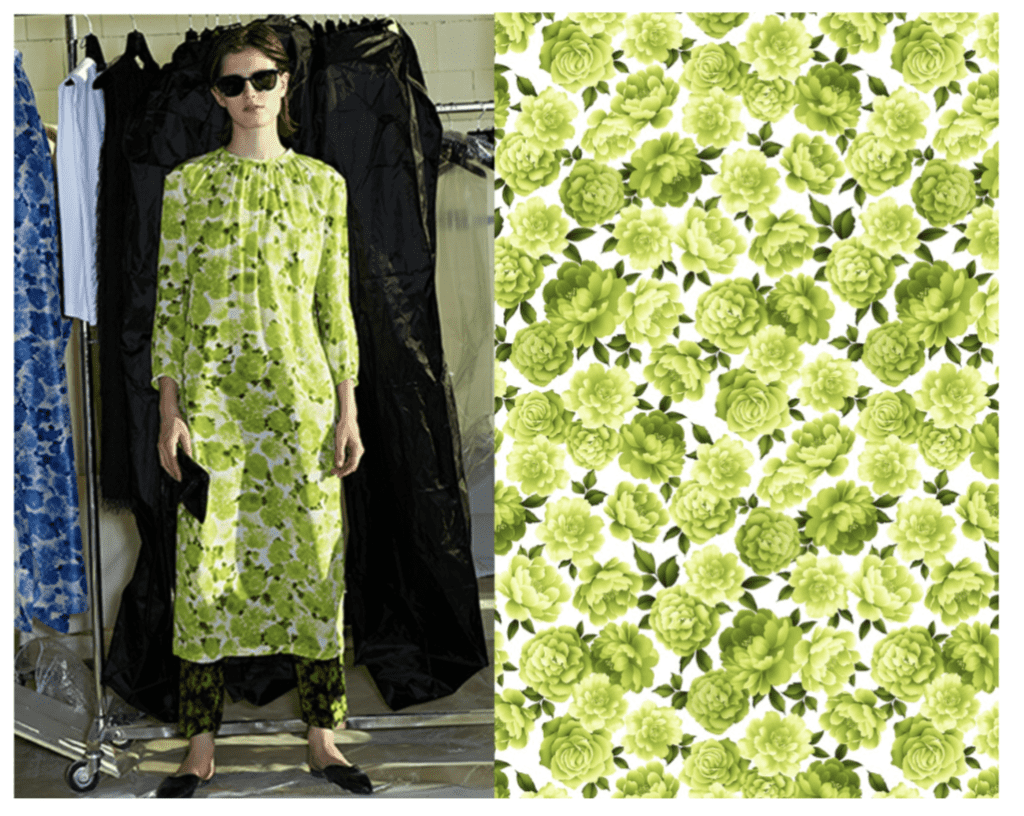

(1) The application of centreless large-area digital printing in garments: centreless large-area digital printing refers to large-area digital printing on the entire garment or on the entire front and back sleeve pieces. As shown in Figure 8, for the ground zero autumn/winter 2014-2015 collection, the garment is simple in appearance and is printed with a high degree of detail using a large centreless grey block print, which uses the subtle colour and brightness of the pattern to create a natural patchwork of large, shaped blocks of colour in the garment. Contrast effect.

Fig. 8 Large area print without centre

(2) Digital printing of individual motifs in the centre of the garment Application: Individual motif printing in the centre refers to the design of a central motif on the front or back of the garment, which intuitively influences the external appearance of the garment through the style of the printed motif. As shown in Figure 9, the eco-friendly T-shirt from the brand ZHI CHANG features a strong biker centre print with the brand’s logo – a gas mask – to create an edgy and stylish rock ‘n’ roll look to a simple T-shirt.

Fig. 9 Individual pattern prints for the centre type

(3) Small area embellishment of the fabric in the local part of the garment and other ways of digital printing applications: small area embellishment of specific parts of the print refers to the small area embellishment of the print in the collar, cuffs, hem, waist, trouser cuffs and other parts of the garment, this type of print is mainly used in the positioning of the garment cuttings print, there are strict requirements for the accuracy of the position of the print, must be complete in line with the requirements of the structure of the garment shape. As shown in Fig. 10, the positioning of the print on the jeans makes a normal pair of bottoms appear more individual due to the uniqueness of the pattern.

Fig. 10 Small area of embellished print on specific areas

In the fashion industry today, the most popular printing technology is digital printing, which allows designers greater freedom to create popular patterns and gorgeous floral designs through different splicing, greatly enhancing the ornamental value of the garment.

3.2.2 Secondary application of digital printed fabrics in clothing design

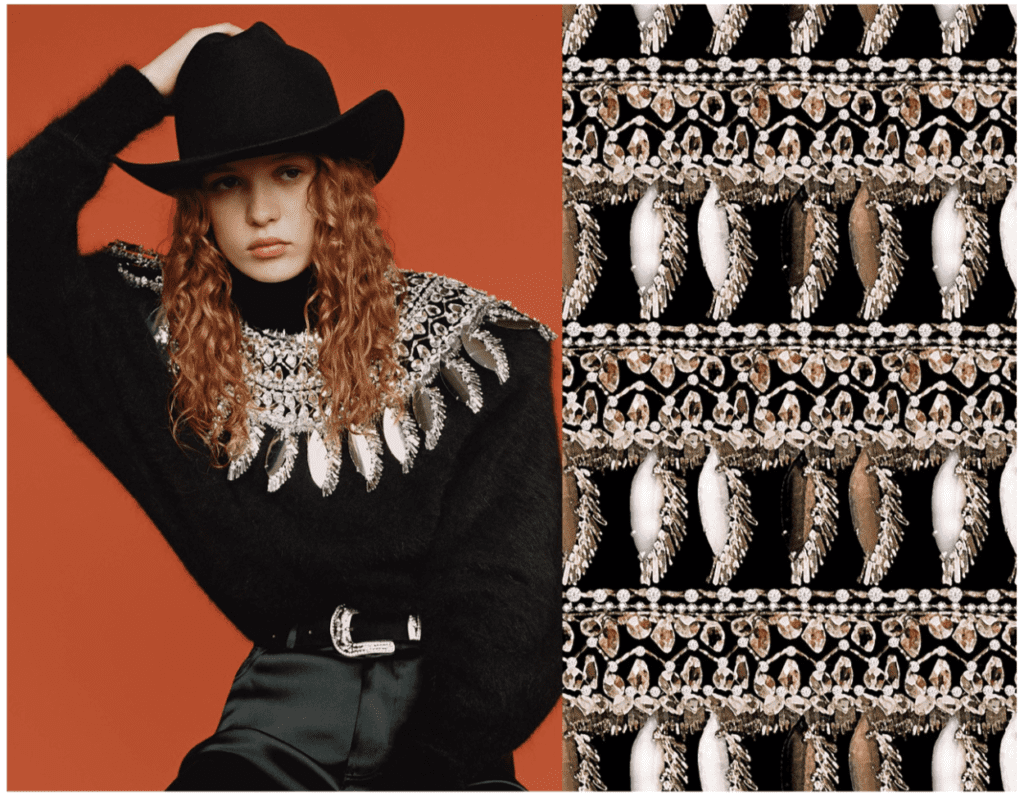

The use of digital printing in the secondary design of garment fabrics refers to the three-dimensional design of garment fabrics after the primary design has been digitally printed, giving them a unique three-dimensional effect. The main techniques used in the secondary design of garment fabrics include: pleating, openwork, inlay and other three-dimensional treatments that add variety and layers to the fabric. The secondary design of digital printing allows for a richer texture and visual hierarchy of the entire pattern, as well as a more refined and sophisticated finish to the garment, making the fabric more visually pleasing to the eye than a simple digital print.

In the shows, such designs abounded, as people were no longer satisfied with plain prints, but demanded more contrasting textures and textures. So, the designers chose to add texture or material contrasts to the prints to give the whole garment a richer feel.

In addition to positioning the fabric onto the dress through digital printing, the embroidery process was also used to gild and embroider parts of the pattern, allowing certain parts of the pattern to be enhanced and highlighted and the fabric to be fuller and richer in texture, thus giving the whole garment a refined and enhanced three-dimensional decorative feel, greatly enhancing the wearability of the garment and fully reflecting the perfect combination of fine craftsmanship and design. The upper body of the garment is cut out and inlaid with bright beads on the base of the digitally printed fabric, creating a strong bumpy, granular texture, while the lower body of the skirt is made from a single digitally printed fabric, with the same pattern theme as the upper garment. The contrast between the upper and lower garments is heightened by the openwork and inlay, which enhances the visual and tactile layers of the fabric, giving the garments a sense of co-ordination and a sense of interest and freshness resulting from the contrast reinforced by the secondary design.

Fig. 11 Secondary design with openwork inlay

Concluding remarks

Digital printing technology is a new environmental innovation in the printing industry, overturning the traditional perception and creation of printed fabrics. Digital printing allows designers to combine the human body with the shape of the garment, ideally configuring the size and position of the pattern, creating high precision digital printed fabrics for primary or secondary use in the garment, and finding ways to enhance the final expression of the design and make the garment more artistically appealing. Digital printed fabric design has become an important part of garment design, highlighting the visual effect while emphasising the taste for fashion and art. Digital print fabrics give this purpose and theme a more powerful expression, allowing fashion designers to take flight and design garments that are more diverse, artistic, personalised and fashionable, thus creating a feast of garments in which a hundred flowers blossom and a hundred schools of thought contend.