Professional Fabric Manufacturer For Apparel

Flexible MOQ:Suitable for startup and Garment Manufacturer

Various of Fabric Option :Satin Silk Jersey Polyester Viscose Cotton

Much Design:accept to online selection

BIG BRANDS’ FAVORITE

THEY TRUST US

Ask For A Quick Quote

We can ship all over the world from our factory in China, which has the most complete range of garment fabrics

Corporation Brand

Grow your business with print-on-demand

Patternvip is a Appare Fabric manufacturer specializing in designing & crafting Print Fabric with the finest materials.

With a full supply chain & our wholly owned manufacturing facilities,we’re able to customize your Fabric down to the smallest detail.

Our accumulated experience of 10+ years & expertise allow us to collaborate with you to elevate your brand through every step of our integrated process,from consultation to final delivery.

SELECTION

THE TABLE OF CONTENT

It is not easy to introduce all aspects of our print fabric, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, below content directory that will jump to the corresponding location when you click on it.

Why Choose Patternvip

One Stop Print Fabic Manufacturer

At patternvip, we live and breathe fabrication technology. That’s why businesses who process polyester cotton rayon acetate silk labeling or packaging to make apparel and garment turn to us when they need new fabric sourcing.

We have over 10 years of experience working with garment manufacturers large and small, and we can specify, design, sourcing modeling for just about any design. Read on the learn a little more about us, and contact us today to ask a question or request a quote on fabric for your business.

10+ Years of Experience

Personalized Move Planning

- Full-value Warranty Service

- 24/7 Availability

Unlimited Fabrics Option

We have more than a hundred kinds of white cloth in stock and qualified inspection standards, so that we can put into production immediately when we receive an order to ensure the delivery time, but also to ensure the quality and efficiency through advance inspection

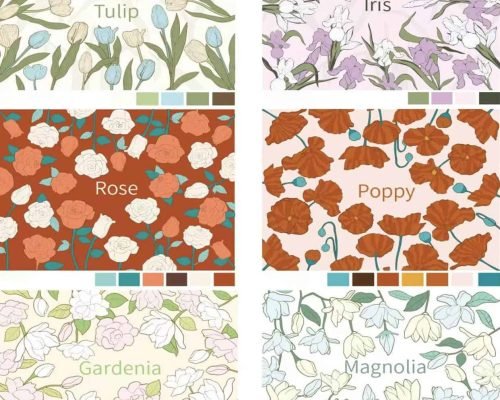

Millions of Ready Pattern

Our professional team of designers can create new original patterns every day, the designers will choose the right fabric to test whether the size of the pattern looks good and whether the details are in place, so that they can quickly adjust the pattern according to the actual effect, in line with the spirit of craftsmanship, committed to the best-looking printed fabrics to provide to customers

Global distribution

Our customers come from all over the world, so our fabrics are packed with the best materials and packaging, whether in bulk, in packages, or in boxes. To ensure that the fabric is in good condition when it reaches our customers.

Benefits of collaboration with Patternvip

The team of innovators and creatives at Patternvip are committed to a new way of doing things. It is our ethos and it is what sets us apart.

Reliable quality

Make a lasting impression by using our industry-leading tech, quality inks, and premium materials. 99.74% of our orders reach happy customers with no issues.

No order minimums

Save money and avoid any leftover stock. The products you sell are created only when your customer places an order.

Experienced Team

In response to customer questions, we use a flexible team approach to solve problems and move the process forward in the fastest and most efficient way

How Does It work

Pick the fabric

Our fabric support Cotton Jersey Satin Silk Canvas Velvet Lycra and so on for Apparel category

Add your design

Settle your artwork or select from our millions of pattern collection to create a stunning design

We print it to order

We make each item just for you. After finished print processes, we will pack your order from China

Fabric Base

Linen

Rayon

Canvas

Chiffon

Jacquard

Jersey

Organza

Embroidery

Mesh

Fleece

Pattern Collection

Our Custom Artwork For Our Clients

-

Pure Linen Digital Print Fabric – 120gsm Woven Textile for Women’s Apparel

Read more -

Bamboo-Cotton Blend Jersey – Ultra-Soft 190gsm Fabric for Babywear

Read more -

Dress Fabric 100% Viscose

Read more -

Swimmear Fabric 87% polyester 13% spandex

Read more -

Peach Crepe 95%polyester 5% spandex

Read more -

Twill Print 100% polyester

Read more -

Satin Bubble 100% Polyester

Read more -

250 Gsm Silky Velvet

Read more

ESTIMATED COST ANALYSIS

The cost drivers for print fabric are the type of process, type of fabric base, design making, and logistics. In the section below, you will see the complete details of the cost.

Fabric Base

Depending on the raw material, there is a slight difference in the price of the cloth body

Type of process

We will suggest the most suitable process to promise the quality and control the cost

Design making

Free: select from our design collection

USD 100 : Make Fresh New if your image image clarity less than 300 pixels

Transportation And Others

WANT TO KNOW MORE SPECIFIC DETAILS?

FAQs

MOST FREQUENT QUESTIONS AND ANSWERS

You can place an order through our mail pan@patternvip.com. If you want to print your own pattern, prepare a file for printing,the files can be shared with us via free file hostings, for example, wetransfer.com.

You can also order printed fabrics from our catalogue. We have more than one million designs that we group into themed collections. When you opt for a particular pattern, it is time to choose the type of fabric and its size.

You do not need to have a registered business if you want to order fabric printing at an attractive price. If you need to order more than 10 running metres of a given material (for example, cretonne), all you need to do is add the fabric to your cart – the discount will be calculated automatically when the transaction is completed. For orders over 20, 30 and 40 running metres, we have prepared discounts, which will be calculated as soon as you add the appropriate amount of fabric to the cart (over 20 running metres – 20% discount, over 30 running metres – 25% discount, and over 40 running metres – 30% discount).

Do you need more than 50 running metres of fabric? Contact us – we will prepare a personalised quote for you.

Of course! We print 20cm x 20cm samples and 48cm x 48cm swatches. Prices of samples and swatches are fixed and do not depend on the type of fabric. You can order samples and swatches of any pattern, both from our catalogue and based on your own design.

Depends on whether you want to do customization your design or not, and also depends on the speed of customs clearance and logistics, but we can guarantee to ship regular fabric whatever FCL or LCL in less than 20 business days.

Waterproof plastic bag + tight woven bag outer packaging, support and then additional carton packaging

We are a trading and manufacturer company, and we select the best suitable factory for your custom print fabric with excellent quality and worry-free service. Please come and see us here!

We offer attractive discounts for bulk orders. The discounts will be automatically calculated when you add the appropriate amount of fabric into your shopping cart. For example, if you order 10 metres of cretonne, you will receive an automatic discount of 10% in your shopping cart. When you order 20 metres, you will receive a 20% discount.

Orders over 50 metres are quoted individually – you will receive an automatic discount for an order over 30 metres in the cart. You can place an order with an automatic discount or contact us, and we will quote your order for you.

We print on various of woven and knitted fabrics. You will find the most complete selection of apparel fabric here,like the most used widely in the apparel manufacturering ,like Voile .Cretonne.Satin.Panama.Gabardine.Cotton.Single jersey.

we can provided you the fabric for sweatshirts, sweatpants, pajamas, sweatpants and jumpsuits, blouses and so on. The addition of Lycra gives the material exceptional flexibility.

China as one of the top three exporters of apparel fabrics in the world, we have a complete product range and excellent quality control.

We can design the pattern according to your requirements (element,color style material,etc.). We will also provide you with expert guidance at the same time, based on our many years of experience in the industry.

We offer you a 6 months warranty on our high-quality fabric and lifetime technical support.

We accept TT. LC. DP. DA payment items

We offer EXW, FOB, CFR, CIF delivery terms.

For small orders,We try to send the fabrics within a maximum of 3-5 working days from the moment of taking the order

We make every effort to process your order as quickly as possible, but please, remember that each fabric is a custom order. Many factors may disturb or prolong the technological process (for example, a malfunction). Therefore, in special cases, the lead time may be extended. We inform our customers about possible problems as soon as possible.

you can come inperson or hire third party like SGS to check the fabric quality

What We Do Realize Your Fashion Ideas

- CUSTOM FABRIC PRINTING

NATURAL AND POLYESTER FABRICS

- 5 DAYS PRODUCTION TURNAROUND

EXTRACT ELEMENTS FROM FASHION INTO PRINT PATTERNS

SHIPPING ALLOVER THE WORLD

- EXPRESS 24 HOUR TURNAROUND AVAILABLE

Ask for quotation

Do you need an individual pricing for your project? Need to know what discount would you get by ordering bigger amount of fabric at once? Drop us a line here, and we will contact you to help you out with everything you need!