Properties of nylon

It is the strongest and most wear-resistant of all fibers. Its abrasion resistance is 10 times that of cotton fiber, 10 times that of dry viscose fiber, and 140 times that of wet fiber. Therefore, its durability is excellent.

Nylon fabric elasticity and elastic recovery is very good, but the small external force is easy to deformation, so its fabric in the process of wearing easy to become wrinkled.

Ventilation and breathability is poor, easy to generate static electricity.

Nylon fabric moisture absorption in synthetic fabrics is a better variety, so the clothing made of nylon is more comfortable than polyester clothing.

There is good resistance to moth, corrosion resistance.

Heat and light resistance are not good enough, ironing temperature should be controlled at 140 ℃ or less. In the process of wearing and using must pay attention to the conditions of washing and maintenance, so as not to damage the fabric.

Nylon fabric is a light fabric, in synthetic fabrics only after polypropylene, acrylic fabric, therefore, suitable for making mountain climbing clothes, winter clothing, etc.

Nylon-6 vs. Nylon-66

The most common nylon products on the market are nylon 6 and nylon 66.

Nylon 6: The full name is poly-caprolactam fiber, made by the polymerization of caprolactam.

Nylon 66: the full name is polyhexanediamide fiber, made from adipic acid and adipamide polymerization.

Generally speaking, the feel of nylon 66 is better than nylon 6, and the comfort of nylon 66 is also better than nylon 6, but it is difficult to distinguish nylon 6 from nylon 66 from the surface.

The common characteristics of nylon 6 and nylon 66: light resistance is poor, in a long time under the sun and ultraviolet light exposure, the strength decreases, the color yellowing; its heat resistance is also not good enough, at 150 ℃, through 5 hours that yellow, strength and elongation decreased significantly,,shrinkage increased. Nylon 6, 66 filament has good low-temperature resistance, and its resilience does not change much when it is below -70℃. Its DC conductivity is very low, and it is easy to generate static electricity due to friction during processing. Its conductivity increases with moisture absorption, and increases with humidity according to the exponential function law. Nylon 6 and 66 filaments have strong resistance to microbial action, and its ability to resist microbial action in sludge water or alkali is second only to chlorine spandex. In terms of chemical properties, nylon 6 and 66 filaments are resistant to alkaline and reducing agent action, but they are less resistant to acid and oxidizing agent action.

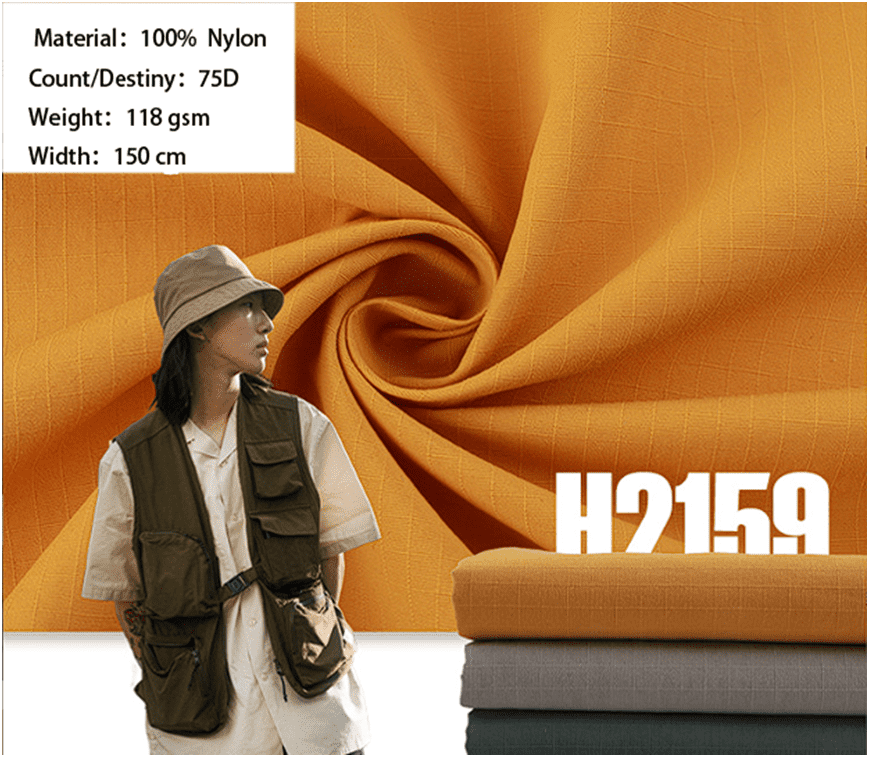

Nylon-fiber fabrics can be divided into three categories: pure spun, blended and interwoven, each of which contains many varieties

Nylon-pure spun fabric

Nylon silk as raw material woven into a variety of fabrics, such as nylon taffeta, nylon crepe, etc.. Because of the nylon filament woven, it has a smooth feel, firm and durable, moderate price characteristics, but also the existence of fabric easy to wrinkle, not easy to return to the shortcomings.

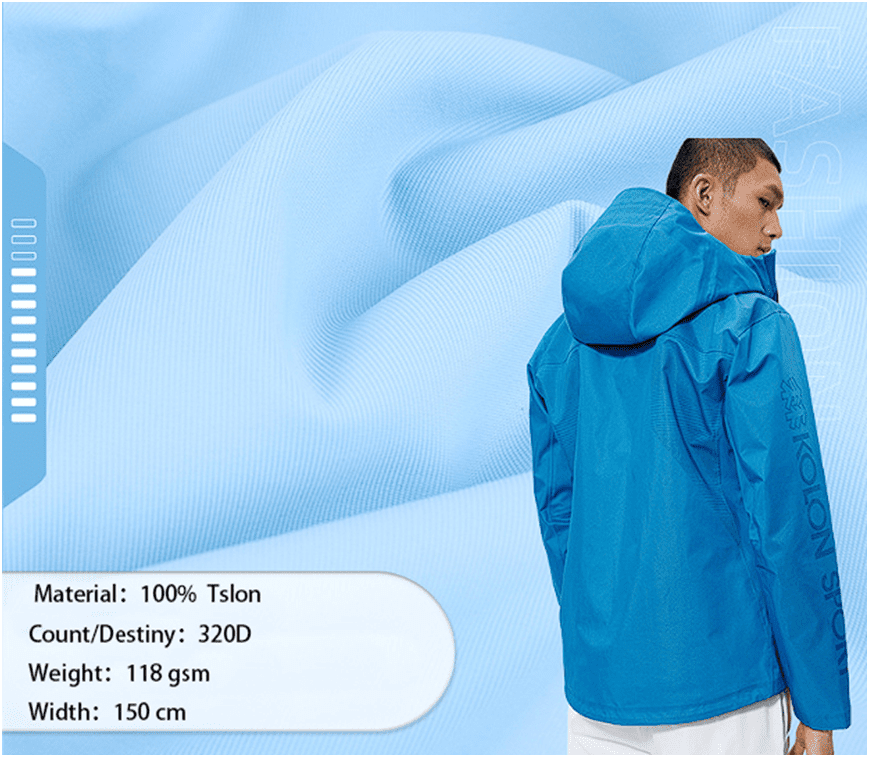

Taslon

is a kind of nylon fabric, including jacquard taslon, honeycomb taslon, full matte taslon and so on. Uses: High-grade garment fabrics, ready-to-wear fabrics, golf garment fabrics, high-grade down garment fabrics, high waterproof and breathable fabrics, multi-layer composite fabrics, functional fabrics, etc.

1.Jacquard taslon: warp yarn adopts 76dtex(70D nylon filament, weft yarn adopts 167dtex(150D nylon air deformation yarn; fabric organization adopts two-fold flat jacquard structure and interweaves on water jet loom. The width of the fabric is 165cm, and the weight is 158g per square meter, with different shades of purple red, grass green and light green. The fabric has the advantages of not easy to fade and wrinkle, strong color fastness, etc.

2.Honeycomb Taslon: the fabric warp yarn is 76dtex nylon FDY, weft yarn is 167dtex nylon air deformation silk, warp and weft density is 430 roots/10cm×200 roots/10cm, interwoven on the water jet loom with faucet, basic choice of double-layer plain organization, the fabric surface forms a kind of honeycomb lattice, the blank first by relaxation refining, alkali reduction, dyeing, after soft, shaping treatment The fabric is firstly refined by relaxation, alkali reduction, dyeing, and then treated by softness and shaping. The fabric is breathable, dry to the touch, soft and airy, comfortable to wear, etc.

3.Full matte taslon: the fabric warp yarn is 76dtex full matte nylon -6FDY, the weft yarn is 167dtex full matte nylon air deformation silk. The most prominent advantage is that it is more comfortable to wear, warmth and breathability.

Nylon spinning

(silk, also known as nylon spinning, for nylon filament woven spinning class silk fabric. After bleaching, dyeing, printing, rolling light, rolling grain treatment of nylon spinning, fabric flat and dense, smooth silk surface, soft feel, light and firm wear-resistant, bright color, easy to wash and dry.

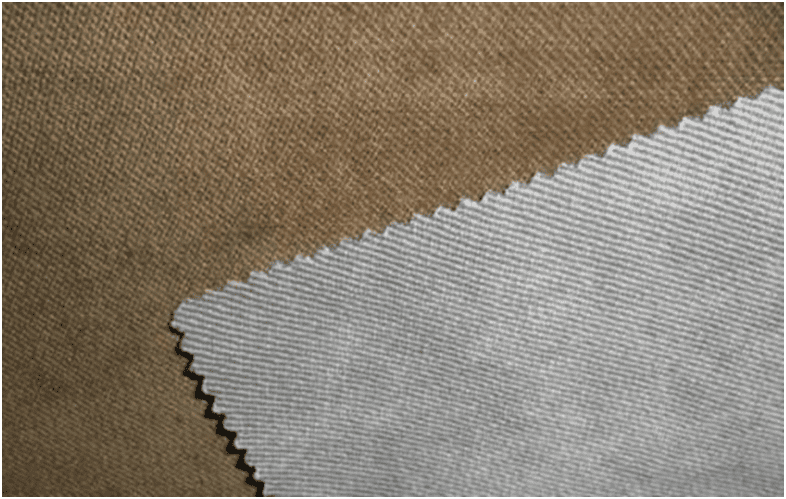

Twill fabic

Twill fabric is woven by twill tissue with clear diagonal pattern, including brocade/cotton khaki, waffle, Crocodile and so on. Among them, brocade/cotton khaki has the characteristics of thick and tight, tough and strong, clear grain, wear-resistant, etc.

Nylon oxford fabric

Nylon-blended and interwoven fabrics

The fabric obtained by blending or interweaving nylon filament or staple fiber with other fibers has the characteristics of various fibers.

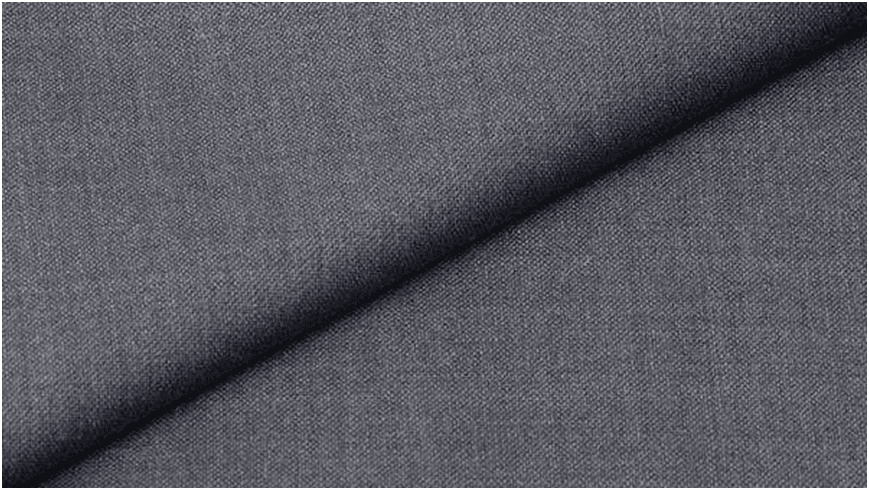

Viscose/Kamwada Tweed

Viscose/nylon wada tweed, there are two blends ratio, one is 15% nylon, 85% viscose fiber; the other is 25% nylon, 75% viscose fiber. The warp and weft yarns are both blended yarns, and it is 2/2 twill fabric. This fabric warp density is greater than the weft density nearly double, so the texture of the tweed body is thick and tight, tough and durable. The surface is smooth and lustrous. The disadvantage is that the elasticity is poor, easy to crease, wet strength is small, shrinkage rate is large, the body becomes hard when washed, easy to sag when wearing.

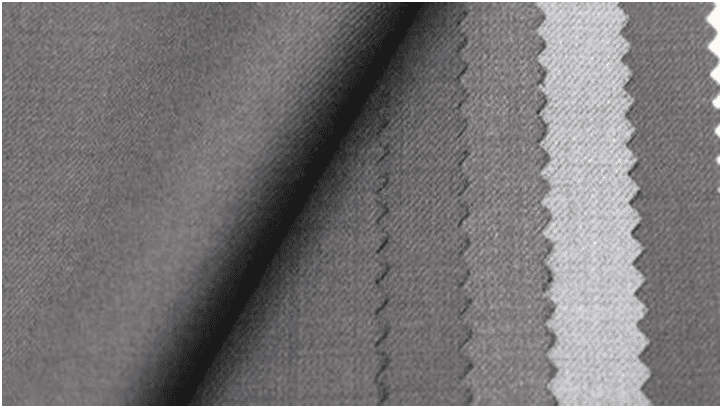

Viscose/nylon vanadine

Viscose/nylon vanadine, called nylon plain tweed, has 15% nylon, 85% viscose fiber and 25% nylon, 75% viscose fiber of two ratios, blended into a double-stranded woven fabric. It is made of plain weave, with the same appearance on the front and back, and feels cool, but not soft enough, and the luster is second only to waffle.

Viscose/nylon beech

Viscose/nylon beep, also known as nylon beep, belongs to 2/2 twill tissue, which has a similar appearance to wada tweed, with a warp density 40% smaller than wada tweed and a weft density close to it. As the surface of beeping is flatter and wider than waders, the interweaving points are clearly visible, but the feel is not as good as waders, and the strength and luster are poor.

Viscose/nylon/wool tweed

Viscose/nylon/wool tweed is worsted, mostly plain tweed, referred to as three-in-one tweed. It is blended in the ratio of 4:4:2, and due to the use of different twisting yarns for warp and weft, the fabric shows a pattern on the tweed surface due to the reflection of light.

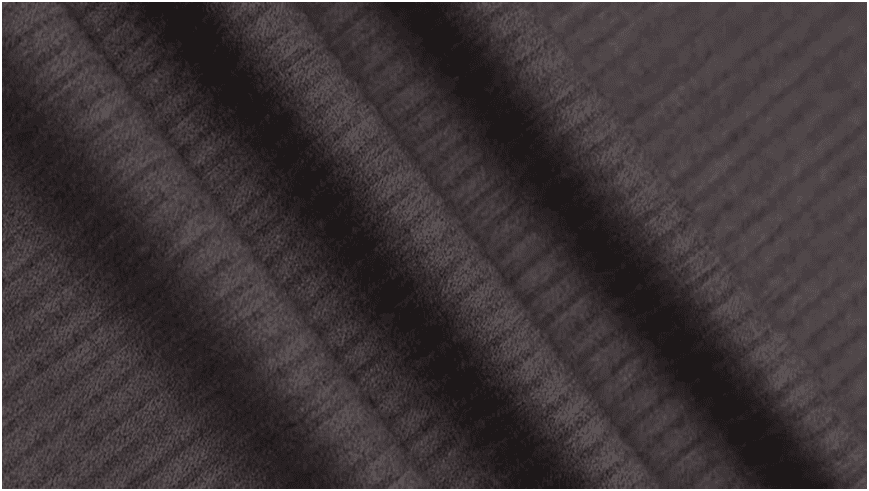

Nylon/viscose/stretch grosgrain

It is warp yarn using spandex nylon covering yarn as raw material, woven on air-jet loom, the blank fabric is loosened, desizing → alkali amount treatment → dyeing (with reactive dyes and disperse dyes) → shaping finishing, etc. The product has both viscose fiber fabric style and nylon fabric luster effect, and both spandex fabric elasticity function; the fabric has cotton feeling, comfort and stretch.