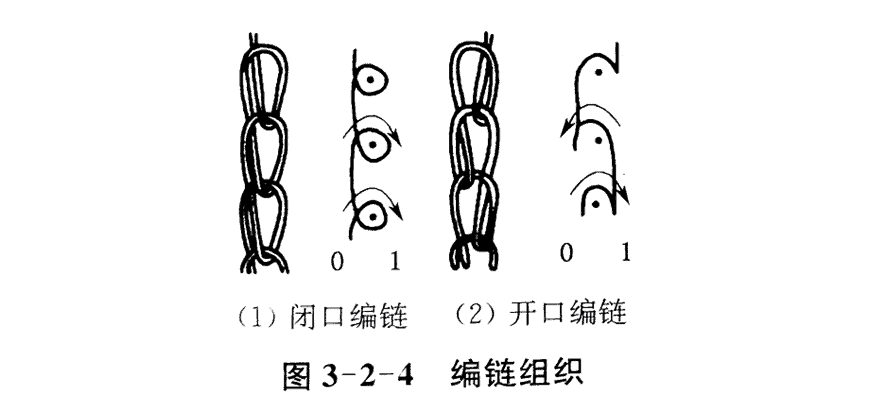

Chain knitting organization

Each yarn always in the same needle mat yarn into a circle of the organization is called chain knitting organization.

Due to the different methods of matting yarn can be divided into closed knitting chain and open knitting chain, respectively, as shown in Figure 3-2-4 (1) (2). The complete organization of the closed-end braided chain is a horizontal column, and its pad yarn number is 0-1//; the complete organization of the open-end braided chain is two horizontal columns, and its pad yarn number is 0-1/1-0//. In the warp knitting commonly used open knitting chain organization, closed knitting chain is generally used in the crochet machine.

There is no connection between the longitudinal rows of each coil of the braided chain organization, and it can only be woven into strips, so it cannot be applied alone, and it is generally compounded with other organizations to form warp knitted fabrics. Warp knitted fabrics such as local use of braided chain organization, due to the adjacent longitudinal rows of no lateral contact and the formation of eyelets, so the braided chain organization is one of the basic methods to form eyelets. The longitudinal elongation of the chain braid is small, and its elongation mainly depends on the elasticity of the yarn. The chain braid can be disengaged against the direction of knitting, so its disengagement can be used as the separation of longitudinal rows between laces.

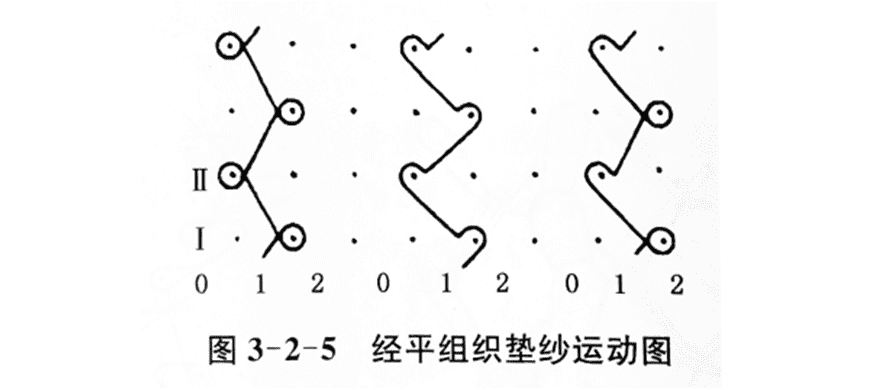

Warping organization

Each yarn in turn on the adjacent two needles mat yarn into a circle of the organization is called the warp flat organization, as shown in Figure 3-2-5.

The loops forming the warp flat can be closed (with a pad yarn number of 1-2/1-0///), open (with a pad yarn number of 2-1/0-1//) or a mixture of closed and open (with a pad yarn number of 1-2/0-1//), with two crosses in a complete organization. If a full comb is used, it can be woven into a blank.

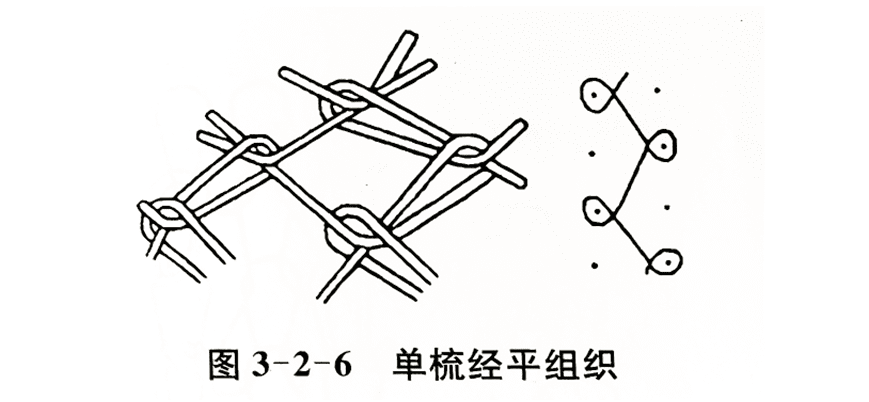

All coils of a single comb warp have unidirectional extensions, i.e. the incoming and outgoing extensions are on one side of the coil, and the bent yarn at the connection between the backbone and the extensions tries to straighten due to the elasticity of the yarn, so that the coil tilts in the opposite direction of the extensions, resulting in a zigzag arrangement in the longitudinal row. The inclination of the coils increases with the elasticity of the yarn and the density of the fabric. In addition, the extension line that passes through the coil ring lone presses the side of the coil backbone and turns the coil into the plane perpendicular to the fabric, making the appearance of the blank similar on both sides while the hemming is greatly reduced, as shown in Figure 3-2-6.

Within the satin organization

Each yarn sequence in three or more needles on the mat yarn into a circle formed by the organization called the warp satin organization.

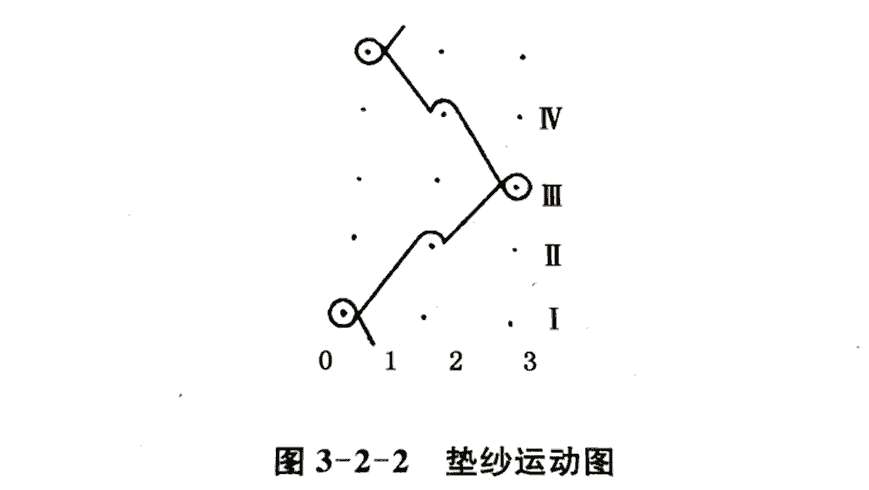

When knitting this organization, the comb at least in three consecutive horizontal columns in the same direction of progressive matting, followed by the opposite side of the question for the matting between the yarn transport. The number of stitches, direction and order of the needle traverse in a complete organization is determined by the pattern requirements. Figure 3-2-2 shows a simple warp satin organization (pad yarn digital 1-0/1-2/2-3/2-1//). Because of the sequence of forming a circle on 3 needles, so often called three needles warp satin organization, sometimes also named according to the number of horizontal columns of complete organization, such as four columns of warp satin organization.

The warp satin tissue is often composed of open and closed coils, usually with closed coils at the steering of the mat yarn and open coils in the middle. The turning coils are tilted because the extensions are on one side and produce eyelets at the turning point. The open loop in the middle has extensions on both sides, but the elastomeric force to straighten the loop is different due to the different bending degree of the connection between the backbone of the loop and the extensions, so the loop will tilt in the opposite direction of the greater bending degree, but this tilt is small and the loop form is close to that of weft flat knitted fabric, so its hemming and some other properties are similar to that of weft flat knitted fabric.

In the warp satin organization, different directions of inclination of the coil traverse different reflections of light, and thus the formation of transverse stripes on the surface of the knitted fabric. When there is an individual coil break, the blank under the action of external force, the coil can be along the longitudinal reverse weave direction disengagement, but will not be divided into two pieces, because the open coil extension line in the coil on both sides, after disengagement there is a floating line and the adjacent longitudinal connection.

Heavy warp tissue

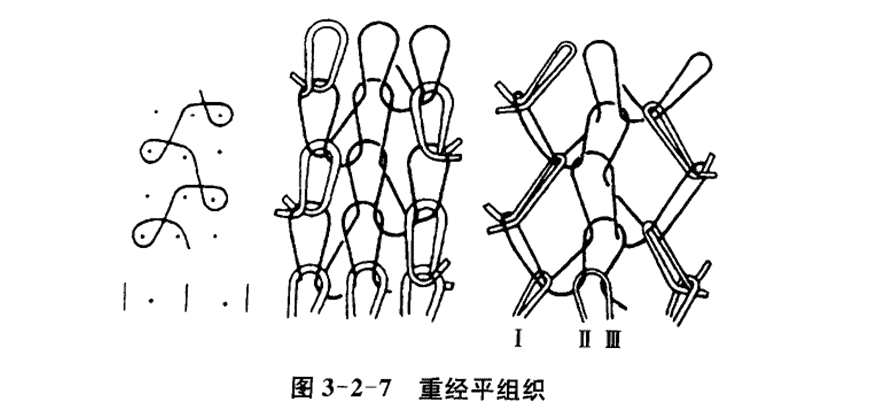

Each yarn in a horizontal column at the same time in the adjacent two needles mat yarn into a circle and the formation of the organization is called heavy warp organization, this type of organization of the guide comb in front of the needle across two stitch distance, in the same horizontal column to form a continuous structure of the loop.

Figure 3-2-7 represents the heavy warp flat organization, which is formed on the basis of the warp flat organization. In each row, each warp yarn is padded on two adjacent needles at the same time, and the latter row is shifted by one gauge with respect to the former row, so that the loops in one longitudinal row are always formed by one yarn, and the loops in the adjacent longitudinal row are formed by the adjacent warp yarns on the left and right in turn. The heavy warp flat tissue can be formed by a single comb with one thread and one empty to form a warp knitted blank.

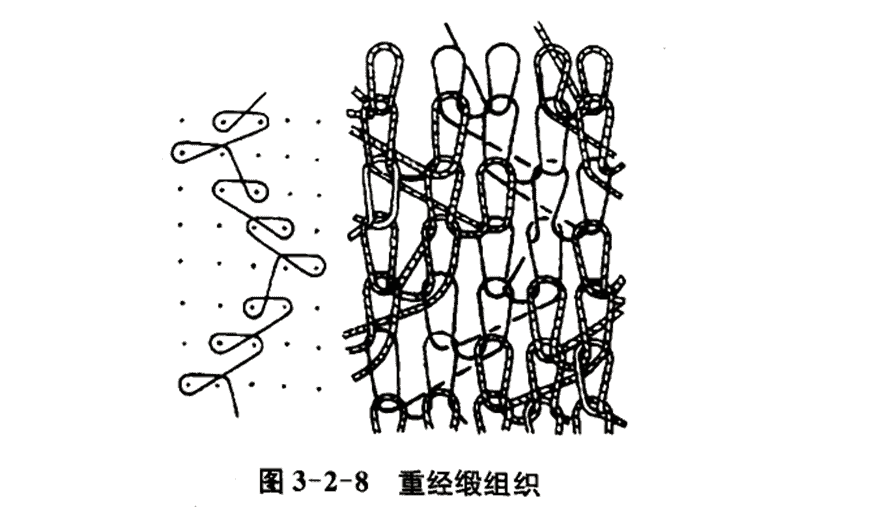

On the basis of warp satin and variation warp satin organization, heavy warp satin organization and variation heavy warp satin organization can also be obtained, Figure 3-2-8 is an example of heavy warp satin organization.

Since there are more open coils in the heavy warp tissue, its nature is between warp knitting and weft knitting, with the advantages of less dispersion and good elasticity.

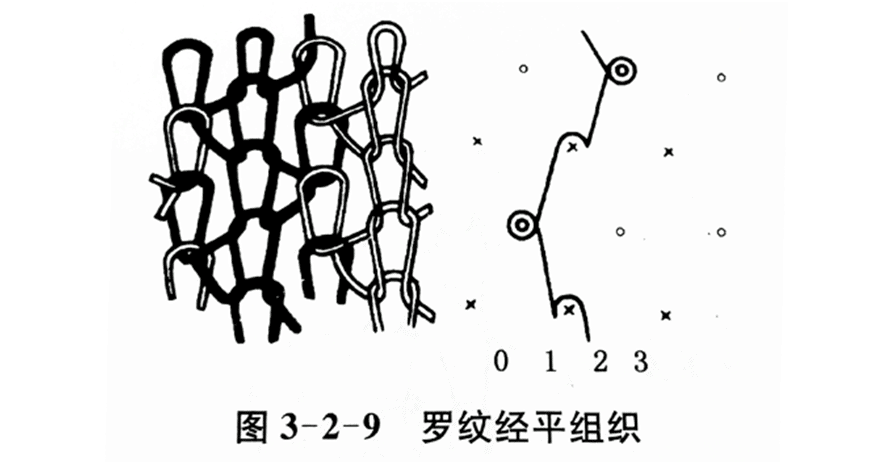

Ribbed warp flat organization

Ribbed warp flat organization is a double-sided organization knitted on a double-needle bed warp knitting machine, knitting before and after the bed of knitting needles staggered configuration, each yarn in turn in the front and back of the bed of a total of three needles mat yarn into a circle. The structure of ribbed warp knitting is shown in Figure 3-2-9. The yarn pads are 2-1, 1-0/1-2, 2-3//.

The appearance of ribbed warp flat tissue is similar to that of ribbed weft tissue, but its lateral extension performance is not as good as the latter due to the presence of extension lines.