Introducción

A. Background on the Textile Industry

The textile industry has been an essential component of human civilization, evolving from hand-spun fibers to the high-tech manufacturing processes of today. Throughout history, the industry has played a significant role in shaping global economies, fashion trends, and even political landscapes. With the advent of new technologies and increased global demand for customized products, the textile industry is undergoing rapid transformation and growth.

B. Overview of Custom Fabric Printing

Custom fabric printing refers to the process of creating unique, customized designs on textiles using various printing techniques. This practice allows for a high degree of personalization and creative expression, which has become increasingly popular in today’s fast-paced, consumer-driven world. From fashion and apparel to home décor and promotional materials, custom fabric printing has become an essential tool for businesses and individuals alike.

C. Purpose and Scope of the Research Paper

This research paper aims to provide a comprehensive overview of the custom fabric printing industry, including market analysis, printing techniques, advantages, applications, challenges, and future outlook. By examining these aspects, we hope to offer valuable insights for businesses, consumers, and researchers interested in the custom fabric printing market.

Market Analysis

A. Overview of the Global Textile Industry

The global textile industry is a diverse and dynamic sector, encompassing the production, distribution, and consumption of various textile products. In recent years, the industry has experienced significant growth, driven by factors such as increased demand for fast fashion, advancements in textile production technology, and a growing focus on sustainability. The custom fabric printing market has emerged as a crucial segment within the textile industry, capitalizing on the demand for personalized and unique products.

B. Trends in Custom Fabric Printing

Several key trends are shaping the custom fabric printing industry, including:

1.Increased demand for personalization: As consumers seek to express their individuality and style, the demand for personalized products has risen, driving growth in the custom fabric printing market.

2.Technological advancements: New and improved printing technologies have enabled more efficient, high-quality, and eco-friendly custom fabric printing processes.

3.Sustainability: As environmental concerns gain prominence, the custom fabric printing industry has begun adopting eco-friendly practices, such as using water-based inks and recyclable materials.

C. Market Size and Growth

The global custom fabric printing market has experienced substantial growth in recent years, with a compound annual growth rate (CAGR) of approximately 10% during the forecast period of 2021-2026. This growth is primarily attributed to the increasing demand for personalized products, technological advancements, and a focus on sustainable practices.

D. Key Players in the Custom Fabric Printing Industry

Some of the leading players in the custom fabric printing market include Spoonflower, Printful, Printify, Contrado, and Jakprints. These companies offer a range of custom fabric printing services, catering to various consumer and business needs.

Custom Fabric Printing Techniques

A. Screen Printing

Screen printing is a traditional technique that involves transferring ink through a stencil or mesh screen onto the fabric. This method is best suited for simple, bold designs and large-volume orders, as it offers high-quality, durable prints at a relatively low cost per unit.

B. Digital Printing

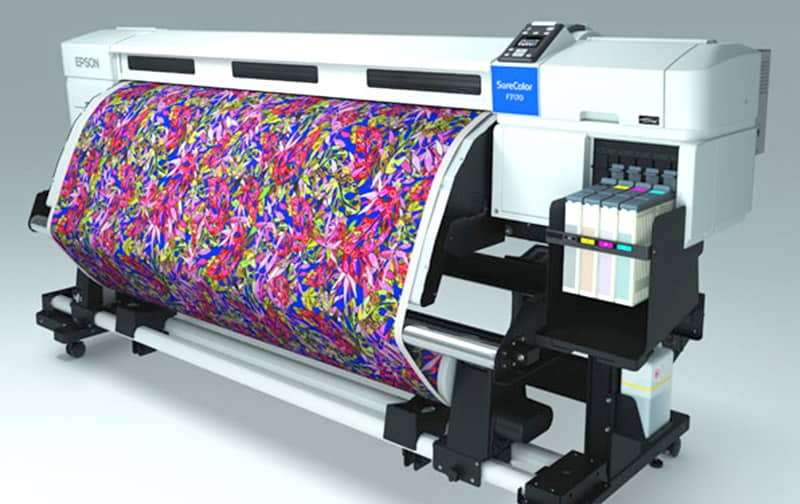

Digital printing uses advanced inkjet technology to print intricate designs directly onto fabric. This method is ideal for small-volume orders, as it offers high-resolution prints, unlimited color options, and quick turnaround times. However, digital printing can be more expensive than other techniques, particularly for larger orders.

C. Dye-Sublimation Printing

Dye-sublimation printing is a process in which heat is used to transfer dye onto fabric, resulting in a permanent, high-quality print. This method is best suited for polyester fabrics and is ideal for producing vibrant, full-color designs. Dye-sublimation printing is known for its durability and resistance to fading, making it an excellent choice for outdoor applications and sportswear.

D. Heat Transfer Printing

Heat transfer printing involves the use of heat and pressure to transfer pre-printed designs onto fabric. This technique is suitable for both small and large orders, offering a wide range of design options and quick turnaround times. However, heat transfer prints may not be as durable as other methods and are more susceptible to fading and cracking over time.

E. Comparison of Techniques

Each custom fabric printing technique has its unique advantages and drawbacks, making them suitable for different applications and needs. Screen printing offers affordability and durability for large orders, while digital printing provides high-resolution prints for small-scale projects. Dye-sublimation printing is ideal for vibrant, long-lasting designs on polyester fabrics, and heat transfer printing offers versatility and quick turnaround times but may lack durability.

Advantages of Custom Fabric Printing

A. Customization and Personalization

One of the primary benefits of custom fabric printing is the ability to create unique, personalized designs that cater to individual preferences and styles. This level of customization enables businesses and individuals to differentiate themselves from competitors and express their unique brand identity.

B. Efficiency and Cost Savings

Custom fabric printing allows for efficient production processes, as digital designs can be quickly and easily modified or scaled. This flexibility enables businesses to save time and resources by streamlining their production processes, ultimately reducing costs.

C. Environmental Sustainability

As the textile industry shifts toward more sustainable practices, custom fabric printing has emerged as an eco-friendly alternative to traditional printing methods. By using water-based inks, recyclable materials, and energy-efficient processes, custom fabric printing can minimize its environmental impact.

D. Quality and Durability

Advancements in printing technology have enabled custom fabric printing to produce high-quality, long-lasting prints. These durable prints can withstand regular wear and tear, making them an ideal choice for various applications, including fashion, home décor, and promotional materials.

E. Advantages over Traditional Printing Methods

Custom fabric printing offers several advantages over traditional printing methods, including greater design flexibility, faster production times, and the ability to produce small-scale orders at an affordable cost.

Applications of Custom Fabric Printing

A. Fashion and Apparel

Custom fabric printing is widely used in the fashion and apparel industry to create unique clothing items, accessories, and textile designs. From custom t-shirts and dresses to bespoke accessories, custom fabric printing allows fashion designers and businesses to express their creativity and stand out in the competitive market.

B. Home Decor and Furnishings

In the home décor and furnishings sector, custom fabric printing enables the creation of personalized items such as curtains, upholstery, pillows, and bedding. This level of customization allows consumers to express their personal style and create a unique living space.

C. Signage and Banners

Custom fabric printing is an excellent option for producing vibrant, durable signage and banners for both indoor and outdoor use. Businesses can leverage this technology to create eye-catching promotional materials and advertisements.

D. Promotional Items and Marketing Materials

Custom fabric printing is widely used to create branded promotional items, such as custom tote bags, t-shirts, and hats. These personalized items can help businesses increase brand awareness and establish a strong brand identity.

E. Other Applications

Custom fabric printing has numerous other applications, including artistic installations, stage backdrops, and even custom-designed vehicle wraps. The versatility of custom fabric printing allows for its use in a wide range of industries and projects.

Challenges and Limitations

A. Technical Limitations

While custom fabric printing technology continues to advance, there are still technical limitations that can impact the quality and feasibility of certain designs. Factors such as color matching, fabric compatibility, and print resolution may pose challenges for some projects.

B. Cost and Time Constraints

Although custom fabric printing can offer cost savings and efficiency for some projects, it may not always be the most economical option. The initial setup costs for certain printing techniques can be high, and the per-unit cost for small-scale orders may be more expensive compared to traditional methods.

C. Quality Control and Consistency

Ensuring consistent quality across multiple prints can be a challenge in custom fabric printing. Factors such as ink quality, fabric type, and printing technique can all influence the final result, requiring close attention to detail and quality control measures.

D. Sustainability Concerns

While custom fabric printing has made strides in adopting more sustainable practices, there are still concerns related to the environmental impact of certain printing techniques and materials. For example, dye-sublimation printing requires the use of polyester fabrics, which are derived from non-renewable resources.

E. Intellectual Property Issues

Custom fabric printing can raise intellectual property concerns, particularly when reproducing copyrighted or trademarked designs. Businesses and individuals must be vigilant in ensuring they have the necessary permissions to use and reproduce such designs.

Future Outlook and Implications

A. Emerging Trends in Custom Fabric Printing

As technology continues to advance, new trends are emerging in the custom fabric printing industry, including the use of artificial intelligence (AI) to create innovative designs, the integration of 3D printing techniques, and the development of eco-friendly materials and processes.

B. Potential Applications and Opportunities

The future of custom fabric printing holds numerous potential applications and opportunities, from wearable technology and smart textiles to large-scale architectural installations. As the demand for personalized products continues to grow, businesses and entrepreneurs can capitalize on the expanding market and develop innovative solutions.

C. Impact on the Textile Industry

Custom fabric printing is poised to have a significant impact on the textile industry, as it offers a more sustainable and efficient alternative to traditional printing methods. This shift toward custom fabric printing is expected to drive innovation and transform the industry landscape.

D. Implications for Businesses and Consumers

The growth of custom fabric printing presents opportunities and challenges for both businesses and consumers. Businesses must adapt to changing consumer preferences and invest in the necessary technology and infrastructure to remain competitive. Meanwhile, consumers can benefit from increased personalization and choice in the products they purchase.

Conclusión

A. Summary of Key Findings

Custom fabric printing is a rapidly growing market within the textile industry, driven by the demand for personalized products, technological advancements, and a focus on sustainability. By understanding the various printing techniques, advantages, applications, challenges, and future trends, businesses and individuals can leverage custom fabric printing to create unique and innovative products.

B. Implications for Future Research

As custom fabric printing continues to evolve, further research is needed to explore new technologies, materials, and processes that can enhance the industry’s sustainability and efficiency. Additionally, studies examining the impact of custom fabric printing on consumer behavior, market dynamics, and the global textile industry will provide valuable insights for businesses and policymakers.

C. Final Thoughts and Recommendations

Custom fabric printing offers immense potential for growth and innovation, transforming the textile industry and providing businesses and consumers with unique, personalized products. To capitalize on this potential, businesses must invest in research and development, embrace sustainable practices, and adapt to changing consumer demands. By doing so, they can create a competitive edge in the expanding custom fabric printing market and contribute to a more sustainable and personalized future.