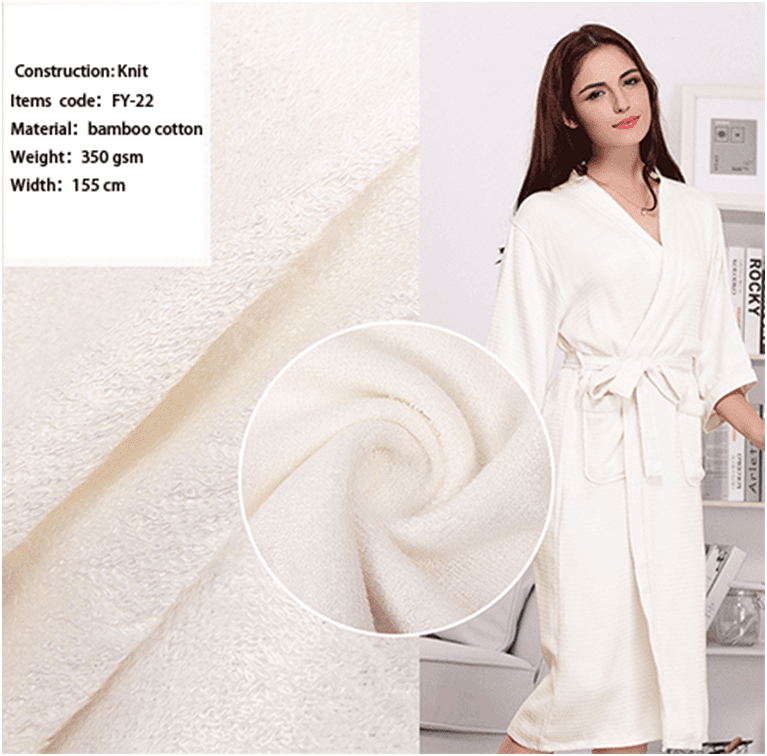

Bamboo fibre, bamboo pulp fibre, bamboo charcoal fibre

Bamboo fibre is divided into bamboo fibre, bamboo pulp fibre and bamboo charcoal fibre, which are often easily confused. Bamboo fibre is made from bamboo pulp by biochemical treatment and then spun, similar to the viscose process or made from bamboo cellulose, bamboo gabions, etc. by physical methods such as steaming. Bamboo fiber is a natural biological agent treatment of moso bamboo products, retaining the natural bamboo fiber anti-bacterial, mite, anti-UV function, but the feel is not as good as bamboo fiber. Therefore, when marketing their products, textile companies generally indicate that the bamboo pulp fibre belongs to bamboo fiber, otherwise it is easy to judge it as bamboo fiber.

Lyocell fibre (including bamboo fiber) is a new type of cellulose fibre developed using the Lyocell fibre production process, and the physical indicators are close to Modal fibre (but the dry and wet elongation is greater than Modal). Bamboo charcoal fibre is a pure oxygen high temperature and ammonia barrier of bamboo to achieve carbonisation, and processed into a nano-level micronised emulsion added to viscose or polyester spinning liquor to form a functional fibre, which is significantly different from the above process.

Cellulose fibres, cellulose ester fibres

In the manufacturing process, there are clear differences between regenerated cellulose fibres and cellulose ester fibres. In the conventional viscose fibre wet spinning production process, the pulp is impregnated with a sodium hydroxide solution, while copper ammonia fibres are replaced with a concentrated ammonia solution of copper hydroxide or alkaline copper salts, resulting in the formation of cellulose xanthate esters. Cellulose ester fibres are made from cellulose, for example by esterifying the hydroxyl groups of cellulose to produce cellulose acetate, which is spun by dry or wet spinning. The dry strength of copper ammonia fibres is similar to that of viscose fibres, but the wet strength and abrasion resistance is better than that of viscose fibres, and the use of a certain percentage in woollen products can significantly improve the smoothness and lustre of the fabric. Acetate fibres are thermoplastic fibres with long-lasting ironing resistance, plus low modulus, soft hand, not easy to wrinkle, good elasticity and excellent drapability. Both of these fibres are commonly used in high-grade silk or knitted fabrics, and are an option in terms of good value for money.

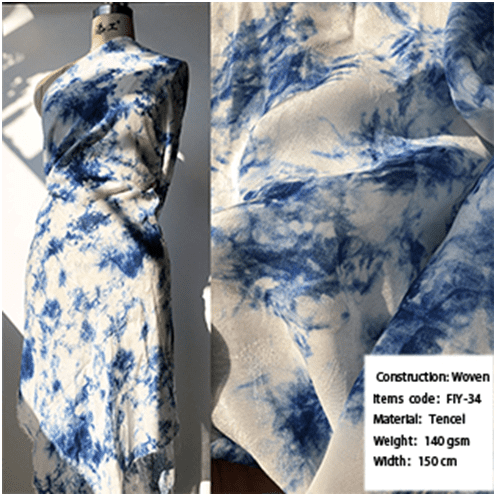

Tencel (Tencel), Lyocell (Lyocell)

Lyocell is known as the “green fibre of the 21st century”, it is a recycled cellulose fibre that uses N-Methylmorpholine-N-oxide (NMMO) as a solvent for wet spinning. The waste is naturally degradable and 99.5% of the amine oxide solvent from the production process can be recycled. “Very low toxicity and no environmental pollution”.

However, the industry and the media, and even some experts in academic reports or papers, often compare “Tencel®” y “Lyocell” as two fibres, comparing Tencel with Lyocell and other cellulose fibres. In 1980, the Dutch company Akzo (Akzo) first patented the process and product of Lyocell fiber, and the British company Courtaulds (Courtaulds) was one of the first manufacturers to develop Lyocell fiber. Akzo Nobel then acquired 65% of Courtaulds’ shares and founded Acordis. Lenzing Austria eventually acquired the Tencel Group of companies, a division of Acordis Corsadi BV, and since then Lenzing has dominated the production of Lyocell fibres and since March 2005 Lenzing has decided to use the trade name “Tencel®” for all its Lyocell fibres. for all Lyocell fibres in the group. During this period Tencel® was produced by Courtaulds in the UK.

Tencel® and Tencel® are therefore trade names for the Lyocell fibres produced by Lenzing, and represent a trade name for a fibre product rather than a classification of fibre components. Since they are trade names, they need to be accompanied by the registered trade mark symbols, otherwise they are misrepresentations. Just like polyester (polyester) fibres, which are available in PET, PBT, PTT, cationic dyeable polyester, etc., Lyocell is the name of a broad category of fibres, with common types of Lyocell fibres including filament and staple fibres, mainly Newcell® from Akzo Nobel, and Lyocell staple fibres such as Tencel®, Alceru®, Cocel®, Acell®, etc. These varieties are all made from wood pulp meal. The most used and most widely used by spinners is Lenzing Lyocell non-primary Tencel® A100, while Tencel® LF low prime and G100 prime are used for post-processing and for special needs. Therefore, when writing a paper referring to Lyocell or Lysol fibres, it is important to specify which trade name is used and not to compare Lyocell in general with other manufacturers’ recycled fibre products, which may cause confusion between the individual and the overall concept.

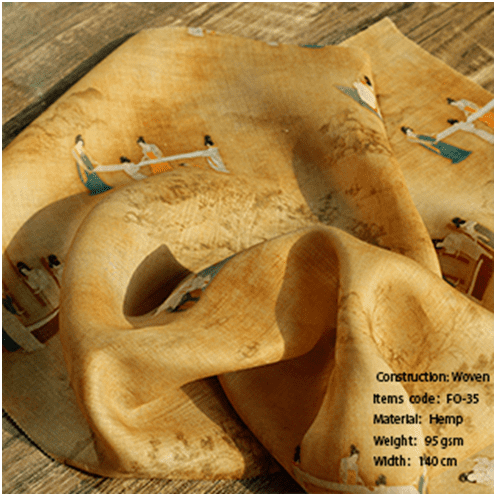

Hemp fibre, hemp pulp fibre

China’s hemp fiber production in the world’s first, but because hemp fiber pretreatment, including permaculture, moisture, pre-loosening, etc., the treatment process is complex, long processing time, high technical requirements, damage to equipment, general cotton spinning mills are difficult to get involved. For this reason, the Chinese Academy of Textile Science since 2005 to start Lyocell fiber localization technology research and product development work, in the research and development of “bamboo”, “hemp” resources on the use of environmental protection has made considerable achievements. Similar to bamboo fibre, hemp fibre is also divided into two types: raw hemp fibre and hemp pulp viscose fibre made from hemp as the cellulose donor. Hemp fiber and bamboo fiber, like the original, using mechanical separation, flash processing and chemical degumming extraction to get. Hemp pulp viscose fibre is a recycled cellulose fibre spun by the wet method, the waste can be naturally degraded, there are currently sage fibre, lyocell fibre, hemp selvage fibre, silk hemp fibre, etc. By the way, it is often encountered that the TM code is added to the upper right corner of the trade name, which is different from the trademark®. TM indicates that the trademark has been applied for to the State Trademark Office and the Notice of Acceptance has been issued to prevent others from filing duplicate applications.

ShengmaTM is (Hebei Jigao Chemical Fibre), made from yellow-red hemp, ramie and flax, using the processes of steaming, bleaching, gum making, spinning and post-treatment to retain the antibacterial properties of hemp; Lai MaTM (Jilin Chemical Fibre), with a serrated fibre cross-section and longitudinal distribution of grooves. It is characterised by a high wet modulus, more than three times that of ordinary cellulose fibres, and is not easily deformed; Hemp SelleTM (Jutecell Hengtian Hailong), made from jute, is a differentiated viscose fibre, retaining the hollow shape of the original hemp, maintaining the characteristics of anti-bacteria and anti-mould, moisture absorption and fast drying; Silk HempTM (Shandong Yinying), based on hemp pulp fibre, using ultra-fine pulverisation technology, the silk protein powder is made from viscose As a carrier, through cross-linking, blending technology, the formation of hemp pulp modified protein cellulose fiber, to overcome the shortcomings of viscose soft, skeletonless, both the feel and luster of silk, but also the texture of hemp.