Recubrimientos en impresoras digitales de inyección de tinta.

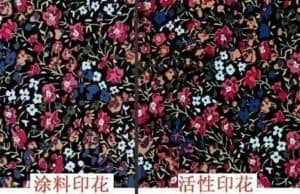

The traditional printing methods used in printing and dyeing industry are reactive dyes, disperse dyes, acid dyes and coating direct printing; among them, reactive dyes, disperse dyes and acid dyes printing are commonly used by the majority of printing and dyeing manufacturers because of their printing patterns with bright colors, full colors, soft fabric feel and clear pattern outline; many foreign trade orders also add some special requirements, such as chlorine bleaching resistance, oxygen bleaching resistance, dry cleaning resistance, etc.. Therefore, we must use the latest technical means to adapt to the requirements of the market, otherwise a very passive situation will be formed and the development of the industry will be hindered. In this case, people will naturally think of non-polluting or less polluting printing method a coating printing.