Roman Fabric

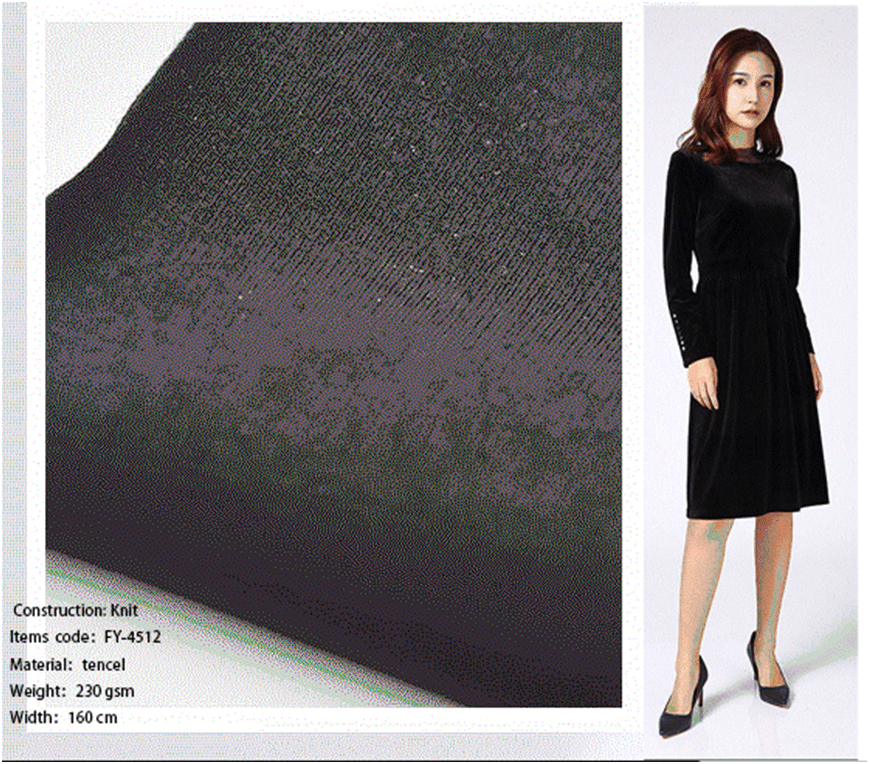

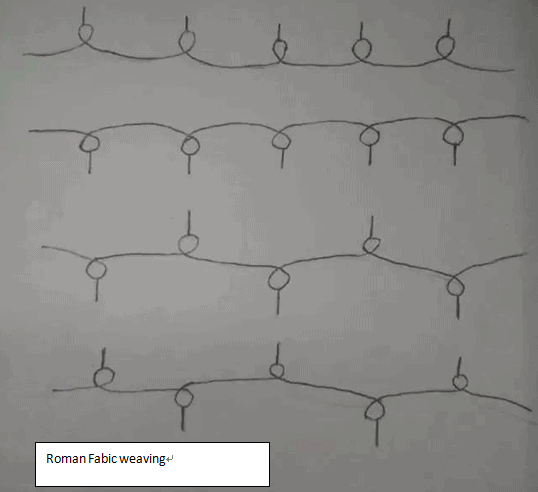

Roman cloth is a knitted fabric, weft knitted, made by double-sided large circular machine. It is also called ponte-de-roma, commonly known as chicken-fighting fabric.

Characteristics of Roman Fabric

(Official statement) Roman fabric is four ways a cycle, the cloth surface is not ordinary double-sided cloth flat, slightly slight and not too regular horizontal stripes.

Roman fabric features

Roman fabric is not easy to stick to the hair, dust, dirty and easy to wash! Stretchy, with a wide range of handfeel, soft and wide! Can meet different design needs! So it is mostly used for middle and high grade garments, tops, pants, jackets and other categories.

Because the Roman fabric is thicker, stopping the mouth flat is not easy to take off the yarn, so many clothing styles use this excellent characteristic of the Roman fabric to do hairy edge design! Let a simple clothes become rich in design and characteristics! But because the elasticity of the Roman fabric is very good, generally contains 6 percent of spandex! Burlap stop at the spandex yarn has been cut off, if a long time under pressure, distortion, high temperature will cause spandex yarn aging, fracture, shrinkage! Make clothes deformation can not recover! So due to improper wearing and washing may make the Roman fabric clothes burlap stop appear wavy effect!

Test Analysis

1、How to disassemble the Roman cloth

First disassemble one side, if you can’t demolish the other side, (double-sided cloth upside down in the direction of the starting circle is good to demolish, if the direction of the starting circle, it will be more difficult to demolish; single-sided cloth like sweat cloth, both sides are very easy to disassemble) If you still can’t disassemble, then tell you a trick! One side of the cloth cut into the following way, it is easy to disassemble

2、Distinguish the front and back of Roman cloth

Does Roman cloth have front and back side?

Theoretically, there is no difference between front and back side of Roman cloth, if there is only a small piece of cloth, it is difficult to distinguish front and back side, if there is a whole cloth cover, you can determine which side is the face and which side is the bottom according to the shaping pinhole.

(Roman cloth) is a color woven cloth, so the front and the reverse side has a very obvious color difference, positive and negative at a glance.

3、Density

The density of knitted fabric refers to the number of horizontal and vertical stitches in 1cm.

4、Differentiation of raw materials

Black yarn is viscose like burning paper

The white yarn has renewed combustion but the renewed combustion is significantly less than 65T/35R, the preliminary judgment is 80T/20R (for reference only, please refer to the corresponding test standard for accurate identification)

Because the weaving method is four-way a cycle, the surface of the cloth is not flat ordinary double-sided cloth, fabric horizontal and vertical elasticity is better, but the horizontal stretch is not as good as double-sided cloth, generally used as pants, sports and leisure jacket, etc., breathable, soft, smooth, tight, comfortable to wear. The most common problem is the feel of this piece.

Dyeing and finishing process of 40sN/R Roman cloth: cloth preparation – gas steaming – predetermined type – dyeing – fabric management – drying – into a fixed.

Dyeing process: this method is a Yu two-step ordinary dyeing process, if the color fastness requirements are relatively high after the overflow 6 minutes first 60 ° over acid put off and then wash water and then dye acid fastness can be increased by about 0.5-1 grade.

Shaping process: 130°C gas steam – predetermined type 185°C * 50m/min under the machine door width according to the requirements to do (specific depending on the performance of the dyeing cylinder) gram weight pull light about 100 grams, dyeing color out of the cylinder dehydration Rei cloth drying, drying process: 180°C as much as heavy drying, plus silicone oil according to the requirements of the specifications of the finished product shaping, two hand feel style process as follows.

1. Smooth and tight hand feeling.

KL837 with 1%

KL817 with 4%

KL811C 2%

If the cloth itself is too soft, add appropriate stiffener to stiffen

2. Soft and smooth feel

KL879T dosage 3%

KL842T dosage 2%

KL811N dosage 1%

The common 30s40s50s60s80s yarn weave, 40s for example, its composition is mostly: 63% rayon + 32% nylon + 5% spandex, the regular feel of two styles: a smooth, tight, bone-like, used as pants 30s40s most, square grams in about 400, the largest amount of this. Another fluffy, soft and smooth used as sports and leisure jacket, common yarn weave 50s60s80s this square gram weight between 200-240. N / R Roman cloth general airflow cylinder dyeing, finishing shaping plus gas steam to do 4 times, the equipment requirements are relatively high, the style mainly depends on the dyeing shaping process.