Purpose of fabric finishing

(1) Changing the appearance of the fabric, such as rolling finishing, fluorescent whitening, etc.

(2) Change the feel of the fabric, such as soft finishing, stiff finishing, etc.

(3) To improve the morphological stability of the fabric, such as stentering, heat-setting finishing of synthetic fibres and their blends, resin finishing, etc.

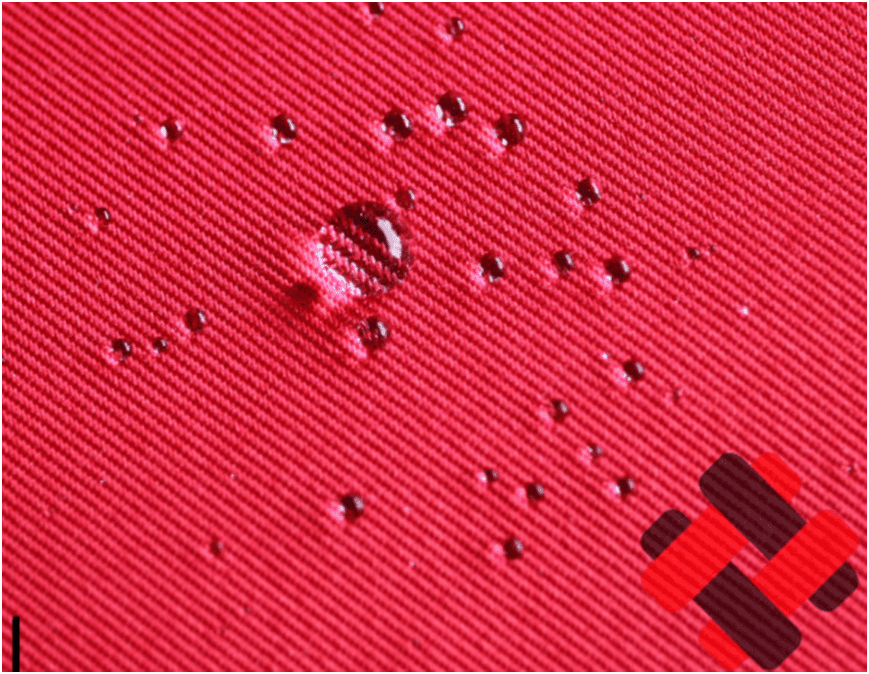

(4) To improve the protective properties of fabrics, such as waterproof finishing, flame retardant finishing, anti-static finishing, anti-radiation finishing and anti-ultraviolet finishing.

(5) to ensure the fabric’s service life, such as anti-mould finishing, mothproof finishing, etc.

(6) Improve the health function of fabrics, such as anti-bacterial and anti-odour finishing, fragrance finishing, negative ion finishing and far-infrared finishing, etc.

Methods of fabric finishing

1. Physical or mechanical finishing. This fabric finishing method uses moisture, heat, pressure and machinery to achieve the purpose of finishing, such as stretched finishing, rolled finishing and electro-gloss finishing. In addition, filling finishing can also be classified as such, which is the addition of filling material to the fabric to improve the feel and weight of the fabric, such as sizing finishing with starch or gum, clay and other minerals formulated into a slurry.

2.Chemical finishing. This finishing method is the use of chemical agents and chemical reaction of textile fibres, so as to change the physical and chemical properties of the fibres. Such as resin finishing, durable waterproof and fireproof finishing, etc.

3.functional fibres and other fibres blended or interwoven, such as heat-resistant flame retardant Nomox fibres and cotton, hemp, viscose and other blended or interwoven, other fibres for flame retardant finishing, antibacterial finishing; anti-static fibres and other fibres blended, such fabrics for anti-wrinkle, anti-oil, waterproof, easy to stain and other three-proof finishing.

If the fabric finishing effect is classified according to the degree of durability, it can be divided into temporary finishing and durable finishing.

(1) Temporary finishing: this finishing effect is easier to disappear after washing or long storage. Such as rolling light finishing, electric light finishing, sizing finishing, etc.

(2) Durable finishing: this finishing effect is not easy to disappear after several washings or dry cleaning. Such as resin finishing, durable waterproof and fireproof finishing, heat setting finishing, etc.

In practice, no classification method can clearly delineate the various fabric finishing methods. Sometimes a fabric finishing method can receive a variety of finishing effects. For example, viscose fibre fabric after resin finishing, both with shrinkage and wrinkle resistance of the morphological stability of performance, but also to change the feel of the fabric and wet strength. Another example is that some chemical finishes are often combined with mechanical finishes to achieve a durable effect.

The current fabric finishing new equipment increases, new fibres and blends a wide variety, finishing methods and content become diversified, tends to be fast and continuous, and even two or more printing and dyeing, finishing process once or a step to complete. Such as anti-wrinkle and anti-oil, waterproof, easy to decontamination finishing combined; with combustion, waterproof and anti-bacterial, anti-static finishing combined together, both to save time, but also to improve the quality of the product.