10 different types of fabric services

Fabric Sourcing

Fabric sourcing involves finding and selecting the right fabrics for a specific product. This process requires a thorough understanding of the various types of fabrics available in the market, their properties, and their suitability for different products. A fabric sourcing expert will work closely with manufacturers, designers, and product development teams to identify the most suitable fabrics based on factors such as cost, quality, durability, and aesthetics.

Fabric Cutting

Fabric cutting is the process of cutting fabrics to the desired size and shape for production. This process requires precision and accuracy to ensure that each piece of fabric is cut to the exact dimensions required for the product. Fabric cutting can be done manually using scissors or a rotary cutter, or it can be done using automated cutting machines for faster and more precise results.

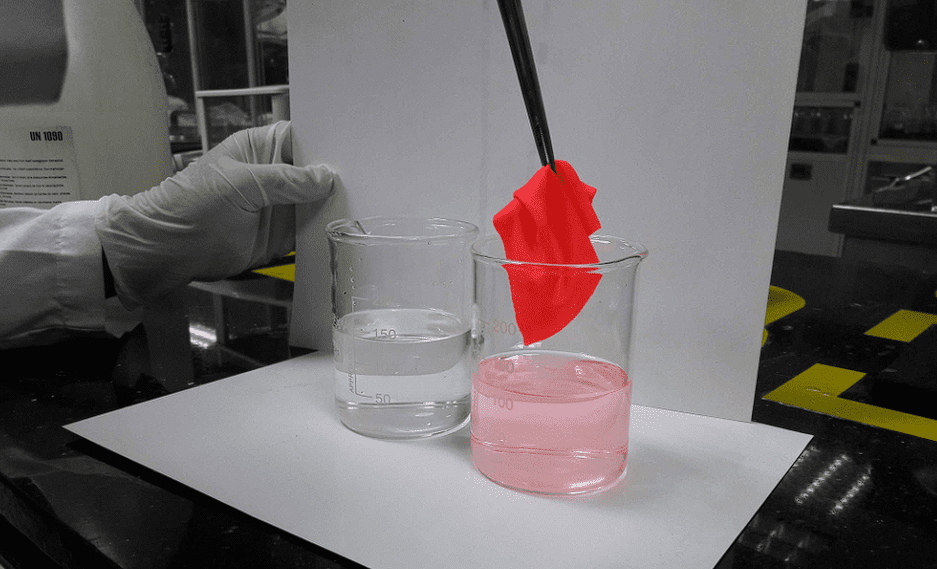

Fabric Dyeing

Fabric dyeing involves coloring fabrics to achieve a desired hue or pattern. This process can be done using natural or synthetic dyes, and can be achieved through a variety of techniques, including immersion dyeing, tie-dyeing, and batik. Fabric dyeing requires expertise in color theory and chemistry to ensure that the color is consistent and long-lasting.

Fabric Printing

Fabric printing involves adding designs or patterns onto fabrics using various printing techniques. This process can be done using screen printing, digital printing, or block printing, among others. Fabric printing requires a combination of technical skill and creativity to ensure that the design is accurate and aesthetically pleasing.

Fabric Finishing

Fabric finishing involves treating fabrics to improve their quality, durability, or appearance. This process can include treatments such as pre-shrinking, anti-static, flame retardant, or water-resistant coatings, among others. Fabric finishing requires an understanding of the specific properties of each fabric, as well as the desired outcome of the treatment.

Fabric Embroidery

Fabric embroidery involves adding decorative stitching onto fabrics using a needle and thread or a specialized embroidery machine. This process can be used to create intricate patterns or designs on fabrics, and is often used for clothing, home decor, and accessories. Fabric embroidery requires a high level of skill and precision to create a clean and polished look.

Fabric Lamination

Fabric lamination involves bonding two or more layers of fabric together using heat and pressure to create a single, thicker fabric. This process can be used to improve the durability, water-resistance, or thermal insulation properties of fabrics, and is often used in the production of outdoor gear and industrial textiles. Fabric lamination requires specialized equipment and expertise to ensure that the layers are bonded evenly and securely.

Fabric Coating

Fabric coating involves applying a layer of chemical or polymer coating onto fabrics to enhance their performance or appearance. This process can be used to create fabrics that are water-resistant, fire-resistant, anti-static, or anti-microbial, among other properties. Fabric coating requires an understanding of the specific properties of each coating material, as well as the desired outcome of the treatment.

Fabric Repair

Fabric repair involves fixing or mending damaged fabrics to restore their function and appearance. This process can involve patching holes or tears, reweaving damaged areas, or reinforcing weak spots in the fabric. Fabric repair requires a high level of skill and attention to detail to ensure that the repair is seamless and does not compromise the quality of the fabric.

Fabric Testing

Fabric testing involves subjecting fabrics to various tests to evaluate their performance, quality, and durability. This process can include tests such as abrasion resistance, tear strength, colorfastness, and shrinkage, among others. Fabric testing is important for ensuring that the fabrics and products produced meet the desired quality standards and can withstand the rigors

5 benefits of using an apparel fabric service:

Pericia

Apparel fabric services have a wealth of knowledge and expertise when it comes to sourcing, cutting, dyeing, printing, finishing, and testing fabrics. They have a deep understanding of the various types of fabrics available in the market, their properties, and their suitability for different products. By utilizing their expertise, manufacturers and designers can ensure that they are using the right fabrics for their products, and that those fabrics are of high quality.

Efficiency

Fabric services have the equipment and expertise to cut, dye, print, and finish fabrics quickly and efficiently. By outsourcing these services, manufacturers and designers can save time and focus on other aspects of product development, such as design and marketing.

Cost-effectiveness

Fabric services can help manufacturers and designers save money by sourcing fabrics at lower prices, and by optimizing the production process to minimize waste and reduce costs. Additionally, fabric services may offer bulk discounts on services such as dyeing or printing, which can further reduce costs.

Quality Control

Fabric services have strict quality control measures in place to ensure that the fabrics and products produced meet the desired quality standards. By utilizing their services, manufacturers and designers can ensure that their products are of consistent quality and meet the expectations of their customers.

5 tips on how to find a reliable fabric service provider

Look for experience and expertise: Look for fabric service providers that have a proven track record of experience and expertise in the type of fabric service you require. Consider the provider’s history, reviews, and testimonials from other clients to get an idea of their reputation in the industry.

Check for certifications and standards

Check if the fabric service provider has any relevant certifications or standards that demonstrate their commitment to quality and safety. Look for certifications such as ISO, Oeko-Tex, or GOTS, among others.

Consider their production capacity

Consider the fabric service provider’s production capacity to ensure that they can handle the volume of fabrics you require for your seasonal development. Make sure that they have the necessary equipment, resources, and personnel to meet your production needs.

Look for transparency and communication

Look for fabric service providers that are transparent about their processes and communication. They should be able to provide you with regular updates on the progress of your project, and be responsive to your questions and concerns.

Evaluate their pricing and terms

Evaluate the fabric service provider’s pricing and terms to ensure that they are reasonable and fair. Consider factors such as minimum order quantities, lead times, and payment terms to ensure that they align with your needs and expectations.

Consider their location and shipping capabilities

Consider the fabric service provider’s location and shipping capabilities to ensure that they can deliver your fabrics to you in a timely and cost-effective manner.

Conclusión

Fabric services play a crucial role in the apparel industry by providing a wide range of services, from fabric sourcing to fabric testing. By utilizing these services, manufacturers and designers can ensure that they are using the right fabrics for their products, that those fabrics are of high quality, and that their production process is efficient and cost-effective. When looking for a reliable fabric service provider, it is important to consider factors such as experience, certifications, production capacity, transparency and communication, pricing and terms, and location and shipping capabilities. By doing so, manufacturers and designers can ensure that they are working with a provider who can meet their needs and help them achieve their goals.