Improve printing wet and dry wipe Key elements

Users are now demanding more and more from digital direct printing, including its versatility, resistance to friction and high colour fastness. The degree of fading of digital direct printing when subjected to external factors (squeezing, rubbing, washing, rain, exposure, impregnation, etc.), such as good colour fastness, makes the textile less likely to lose colour during use.

Chinese Clothing print industry Development

clothing printing mainly refers to t-shirts, sweatshirts, casual clothing, knitted sportswear, children’s clothing, denim clothing, jumpers, individual pattern prints on garments or garments, but also knitted underwear, home wear, women’s clothing continuous pattern printing. The majority of fabrics are cotton weft knitted fabrics, while functional, modified and cotton- and linen-like polyester fabrics are gradually being […]

printing processes commonly used on textile fabrics

Textile fabric pearlescent and luminous printing There are natural and artificial pearlescent, and artificial pearlescent can be extracted from fish scales. Pearlescent does not need to be stimulated by light sources and is resistant to acids and alkalis and high temperatures. Tencel fabrics with pearlescent printing show a soft pearl-like lustre and elegance, with an […]

Coatings in digital inkjet printers

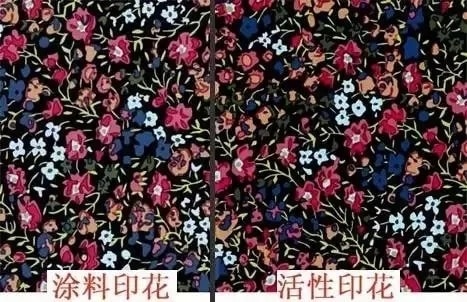

The traditional printing methods used in printing and dyeing industry are reactive dyes, disperse dyes, acid dyes and coating direct printing; among them, reactive dyes, disperse dyes and acid dyes printing are commonly used by the majority of printing and dyeing manufacturers because of their printing patterns with bright colors, full colors, soft fabric feel and clear pattern outline; many foreign trade orders also add some special requirements, such as chlorine bleaching resistance, oxygen bleaching resistance, dry cleaning resistance, etc.. Therefore, we must use the latest technical means to adapt to the requirements of the market, otherwise a very passive situation will be formed and the development of the industry will be hindered. In this case, people will naturally think of non-polluting or less polluting printing method a coating printing.