Acetate fabric, commonly known as acetate fabric, is also known as yasha, which is the Chinese harmonic reading of the English word ACETATE. Acetate (acetate) is a man-made fibre made from acetic acid and cellulose through an esterification reaction. Belonging to the family of man-made fibres, acetate is most like to imitate silk fibres, manufactured using advanced textile techniques, with bright colours, bright appearance, soft and comfortable to touch, and close to mulberry silk in terms of lustre and performance.

The acetate fabric is very skin-friendly and extremely comfortable. The upper body has a feeling of being pampered. And the sheen is very elegant and silky, easily accentuating the gentle side of a woman.

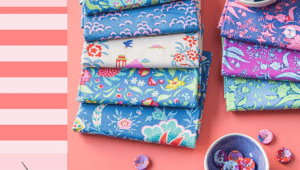

Due to its acetic acid properties it can be dyed with disperse dyes and has very good colouring properties, producing more vibrant colours and excellent shades than other fabrics.

Acetate fabric is very thermoplastic

Acetic acid is very stretchable and does not shrink like silk. It maintains the design well and gives the suit a more three-dimensional look.

Excellent wrinkle resistance

It does not wrinkle or harden or shrink after washing, as the water expansion rate of acetate is much lower than that of other fabrics, so the garment has excellent stability. This stability ensures that the garment is always in perfect condition and does not wrinkle at any time, keeping the garment looking good at all times.

Excellent drape

It has a very soft and silky feel, comparable to real silk, with a gorgeous satin texture, excellent drape and very skin-friendly and breathable!

Optimum comfort

Close to the feel of silk, its fabric contains the right amount of water, close to the skin moisture vaporisation to produce a cool feeling, also has a good breathability, the fabric is delicate and smooth, more close to the skin, comfortable and light.

Diacetate and Triacetate

When it comes to acetate, it is important to talk about its classification. Acetate fibres are produced from wood pulp meal, in which the cellulose is acetylated to form cellulose esterified derivatives, which are then spun in a dry process.

Depending on the degree of substitution of the hydroxyl group (-OH) in the cellulose by the acetyl group, they are classified as diacetate and triacetate.

Diacetate is formed by the partial hydrolysis of a type of acetate, which is less esterified than triacetate. As a result, the thermal properties are less than those of triacetate, the dyeing properties are better than those of triacetate, and the moisture absorption rate is higher than that of triacetate.

Triacetate is a type I vinegar ester formed without hydrolysis, and its degree of esterification is higher. As a result, it is more resistant to light and heat, has poorer dyeing properties and has a lower moisture absorption rate (also known as moisture regain).

Properties of acetate

1. Chemical properties

a. Alkali resistance

Weak alkaline alkalis do not cause damage to acetate fibres and the weight loss of the fibres is minimal. When strong alkalis are encountered, especially in diacetate, deacetylation occurs easily, resulting in weight loss and a consequent decrease in strength and modulus. Under standard washing conditions, it is highly resistant to chlorine bleaching and can also be dry cleaned with perchloroethylene.

b. Resistance to organic solvents

Acetate is completely soluble in acetone, DMF and glacial acetic acid, but insoluble in ethanol and tetrachloroethylene. Based on these properties, acetone can be used as a spinning solvent for acetate, and perchloroethylene can be used for dry cleaning of acetate fabrics, etc.

c. Acid resistance

The acid resistance of acetic acid is good. Common sulphuric acid, hydrochloric acid and nitric acid do not affect the strength, lustre and elongation of the fibres within a certain concentration range; however, they can be dissolved in concentrated sulphuric acid, concentrated hydrochloric acid and concentrated nitric acid.

d. Colourability

Although acetate is derived from cellulose, a large part of the polar hydroxyl groups on the glucose ring of cellulose are replaced by acetyl groups to form esters during the esterification process. The most suitable dyestuffs for acetate fibres are disperse dyestuffs with low molecular weight and similar dyeing rates.

Disperse dyestuffs produce a bright and colourful acetate or fabric with good homogenisation, high dye absorption, high colour fastness and a full colour spectrum.

2. Physical properties

a. Acetate fiber has a certain degree of water absorption, but also has the performance of rapid removal of water after absorption

b. The thermal stability of acetate is good, the glass transition temperature of the fiber is around 185 ℃, the melt termination temperature is around 310 ℃, at the end of the temperature rise, the weight loss of the fiber is 90.78%; the fracture strength of acetate is 1.29 cN/dtex, while the strain is 31.44%.

c. The density of acetate is less than that of viscose and is closer to that of polyester; the strength is the lowest of the three fibres.

d. The elasticity of acetate is relatively good, similar to that of silk and wool.

e. Boiling water shrinkage is low, but high temperature treatment can affect the strength and lustre of the fibres, so the temperature should not exceed 85°C.

Comparison of diacetate with similar fibres

The wood pulp is made from trees grown for many years, the impurities of the wood pulp are removed and filtered and treated with acetic anhydride to form cellulose esters. The vinegar cellulose esters are dissolved, defoamed, sprayed, solidified, drawn and wound to form the vinegar filaments of cellulose fibres.

The second vinegar is a type I vinegar ester formed by partial hydrolysis, its vinegar degree is lower than that of the third vinegar. Therefore, the heat performance is less than that of triacetin, and the dyeing performance is better than that of triacetin (diacetin is generally dyed at 85~100℃, triacetin is generally dyed at 130℃), and the moisture absorption rate is higher than that of triacetin (at a relative temperature of 65%, the moisture regain rate of diacetin is 6.5%, while that of triacetin is only 3.5%).

Diacetate fibres resemble real silk, have a soft hand, are brightly dyed, beautiful and sun-resistant, but their strength and abrasion resistance are poor and they are mainly used to make 84% of clothes (such as underwear and knitwear); 15% of home decorations (such as furniture covers); and about 1% of industrial use (such as car cushions).

Fibres spun from cellulose triacetate have many properties similar to those of true synthetic fibres (e.g. polypropylene fibres, nylon and polyvinyl acetate). The chemical fibres are hydrophobic, heat treatment improves crystallinity, the fabric is easy to finish, wrinkle resistant, dimensionally stable, easy to dry and its most important feature is its stable form. Acetate fibres have textile properties similar to those of synthetic fibres.

How to take care of it

1: The fabric itself is not electrically charged and does not generate static electricity, so it will not become mouldy or moth-eaten when placed on a daily basis.

2: Acetate fabric performance is close to silk, people will also use it as a substitute for silk. Before wearing ironing temperature must not be too high, low temperature ironing must play steam, not dry ironing.

3:, Acetate fabric gives extremely good comfort, but when wearing it, try to reduce the pulling on the garment.

4: The same suit should not be worn for more than 7 days in a row. After 2-3 days of normal wear the clothes need to be hung on special hangers to allow the fabric fibres to have a natural repair process.