Best Practices

Eco-Friendly Materials

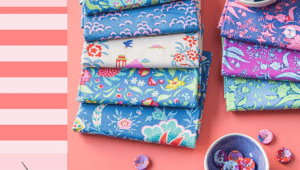

Using eco-friendly materials is a key best practice in sustainable garment manufacturing. Chinese manufacturers are exploring alternatives to conventional materials, such as organic cotton, recycled polyester, and bamboo, to reduce the environmental impact of garment production.

Energy Efficiency

Energy efficiency is another important aspect of sustainable garment manufacturing. Chinese manufacturers are investing in renewable energy sources, such as solar and wind power, to reduce their carbon footprint. They are also optimizing production processes to reduce energy consumption and waste.

Water Conservation

Water conservation is a critical issue in garment manufacturing, as the industry is one of the largest consumers of water. Chinese manufacturers are adopting water conservation measures, such as using closed-loop systems and water-efficient equipment, to reduce water consumption and wastewater discharge.

Ethical Labor Practices

Ethical labor practices are also a key aspect of sustainable garment manufacturing. Chinese manufacturers are working to improve working conditions for employees, ensuring fair wages, reasonable working hours, and safe working conditions.

Herausforderungen

Lack of Awareness

One of the main challenges in sustainability in Chinese garment manufacturing is a lack of awareness among suppliers and manufacturers. Many businesses are still not aware of the importance of sustainability or the best practices for achieving it.

Cost

Another challenge is the cost of adopting sustainable practices. Many Chinese manufacturers operate on thin profit margins and may not have the resources to invest in sustainability initiatives.

Limited Supply Chain Transparency

Limited supply chain transparency is also a challenge in sustainable garment manufacturing. It can be difficult for manufacturers to trace the origin of materials and ensure ethical labor practices throughout the supply chain.

Policy and Regulation

Policy and regulation can also be a challenge in sustainable garment manufacturing. The regulatory landscape is complex, and there is a lack of standardized guidelines for sustainability in the industry.

Abschluss

In conclusion, sustainability is becoming increasingly important in Chinese garment manufacturing, and businesses are taking steps to adopt eco-friendly and ethical practices. Best practices such as using eco-friendly materials, energy efficiency, water conservation, and ethical labor practices are being adopted, but challenges remain, including a lack of awareness, cost, limited supply chain transparency, and policy and regulation. By addressing these challenges and embracing sustainable practices, Chinese garment manufacturers can stay competitive and meet growing demand for eco-friendly and ethically produced clothing.

Häufig gestellte Fragen

- What are eco-friendly materials in sustainable garment manufacturing?

Eco-friendly materials in sustainable garment manufacturing include organic cotton, recycled polyester, and bamboo, which are alternatives to conventional materials that reduce the environmental impact of garment production.

- What is energy efficiency in sustainable garment manufacturing?

Energy efficiency in sustainable garment manufacturing involves investing in renewable energy sources, such as solar and wind power, and optimizing production processes to reduce energy consumption and waste.

- Why is water conservation important in garment manufacturing?

Water conservation is important in garment manufacturing because the industry is one of the largest water consumers. Chinese manufacturers are adopting measures such as closed-loop systems and water-efficient equipment to reduce water consumption and wastewater discharge.

- What are ethical labor practices in sustainable garment manufacturing?

Ethical labor practices in sustainable garment manufacturing include fair wages, reasonable working hours, and safe working conditions for employees.

- What are the challenges in sustainable garment manufacturing?

Challenges in sustainable garment manufacturing include a lack of awareness, cost, limited supply chain transparency, and policy and regulation.